10

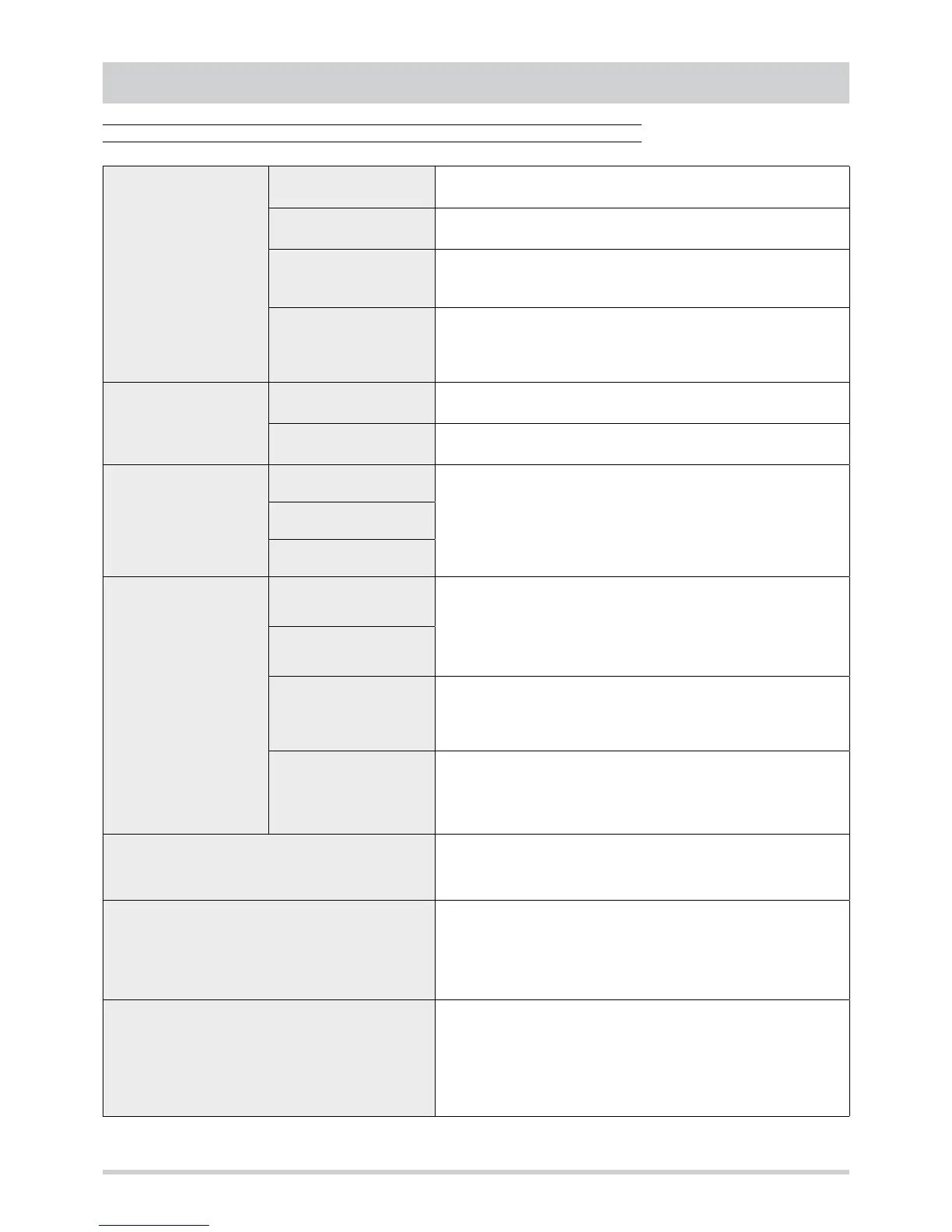

GENERAL FEATURES

Options

Constructive

configuration

VB - Base version It only allows to operate with all return air.

V1 - 1 damper version It allows to operate with a fixed percentage of outdoor fresh air, manually set.

V2 - 2 dampers version

It allows to operate with a variable percentage of outdoor fresh air, adjusted by

the unit controller according to free cooling and air quality control algorythms.

V3 - 3 dampers version

It allows to operate with a variable percentage of outdoor fresh air, adjusted by

the unit controller according to free cooling and air quality control algorythms.

Moreover it manages the expulsion of an air flow rate equal to the outdoor fresh

air flow rate.

Air flow

position

Standard

(frontal or upwards)

For the models of frame 1 and 2 the standard position is frontal while for the

models of frame 3 the standard position is upwards.

Downwards It is available for all the models and it allows a more compact installation.

Internal fan

Standard

In order to adjust the performances of the internal fan to the air flow rate and

available head values required, for each model are available three type of inter-

nal fan that are different for pulleys used, electrical motor installed power and in

some cases for the kind of fan used.

The pulley installed on the electrical motor is a variable diameter type pulley

and allows, within certain limits, to adjust the performance curve of the fan to

the characteristic curve of the plant.

Upsized

Reduced

Heating

integration

Hot water coil

2 or 3 rows

with pipes

It performs the heating function (as heat pump integration or replacement), the

post heating function (in cooling mode) and the ice protection function. It is

equipped with automatic air vent, drain valve, shut off ball valves at the inlet and

outlet, safety valve (6 bar) and stainless steel condensate tray.

The ball type motorized 3 way valve is managed by the unit controller according

to an on-off logic.

Hot water coil

2 or 3 rows

with 3 way valve

Electrical heater coil

standard or upsized

It performs the heating function (as heat pump integration or replacement), the

post heating function (in cooling mode) and the ice protection function. It is

equipped with safety thermostat and is protected against overcurrents by me-

ans of fuses placed inside the electrical panel.

Condensing

gas heating module

standard or upsized

It performs the heating function (as heat pump replacement) and the ice pro-

tection function. The stainless steel air-fumes exchanger is coupled with a mo-

dulating premixed burner that allows to adjust the power supplied inside a wide

operating range and to maximize the exploitation of the fumes condensing heat

also at part loads.

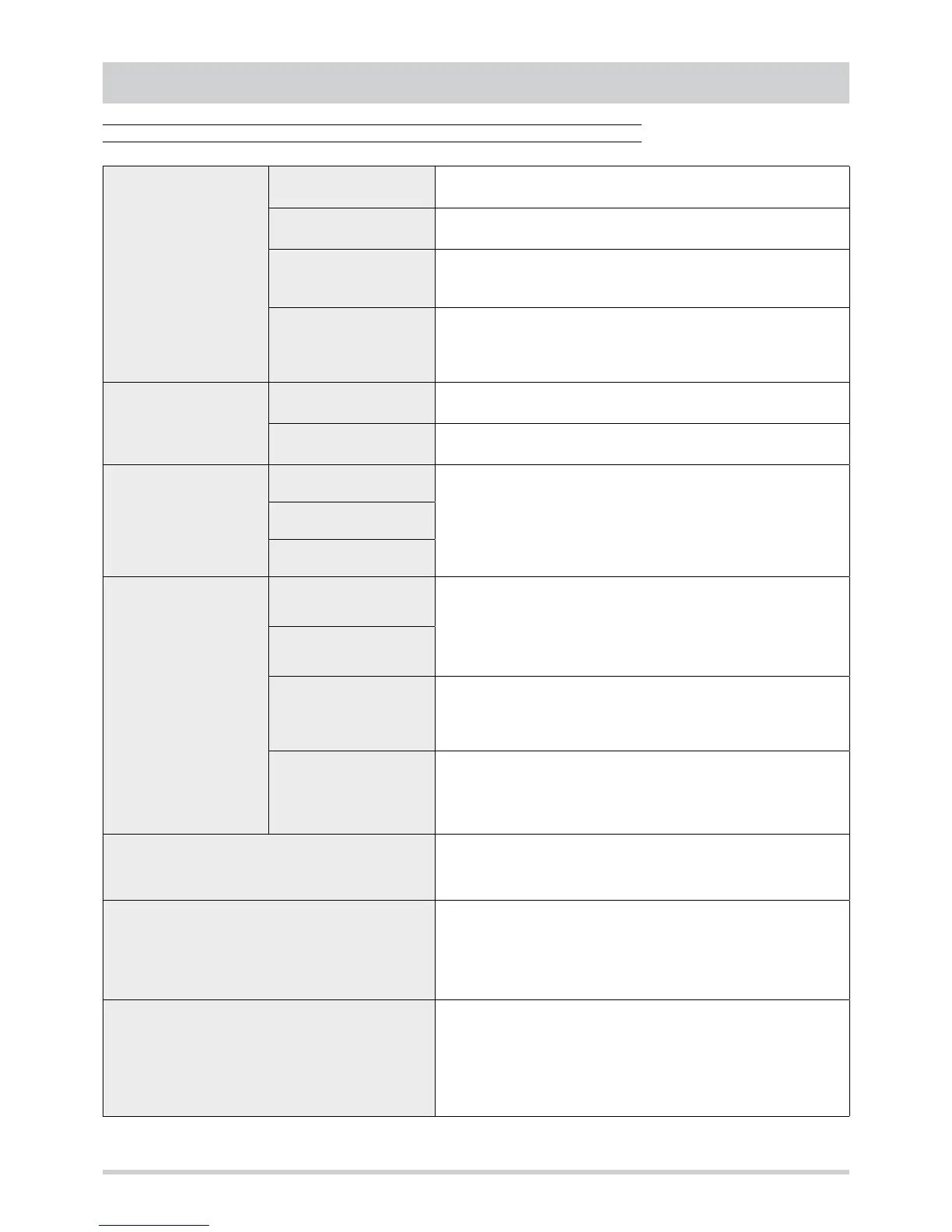

Low noise acoustic setting up

It allows to reduce the noise emissions produced by the unit through the insula-

tion of the walls of the compartment that contains the refrigerant circuit and the

use of sound absorbent jackets on the compressors. Such setting up includes

also the modulating control of the external fans.

Air flow silencers

They allow to reduce the noise transmitted to the conditioned ambients through

the air ducts. They are realized by mineral wool acoustic baffles with fiberglass

coating placed downstream the centrifugal internal fan.

They are available only for the models of frame 1 and 2 with standard "Air flow

position" option.

External fans control

The modulating control of the external fans allows to operate with low outdoor

temperatures in cooling and high outdoor temperatures in heating and permits

to reduce noise emissions in such operating conditions.

The fans rotational speed is modulated continuosly by a phase cut device that

allow to control the condensing pressure (in cooling) and the evaporation pres-

sure (in heating) according to the value read by the temperature probe placed

on the liquid line.

Loading...

Loading...