7

GENERAL FEATURES

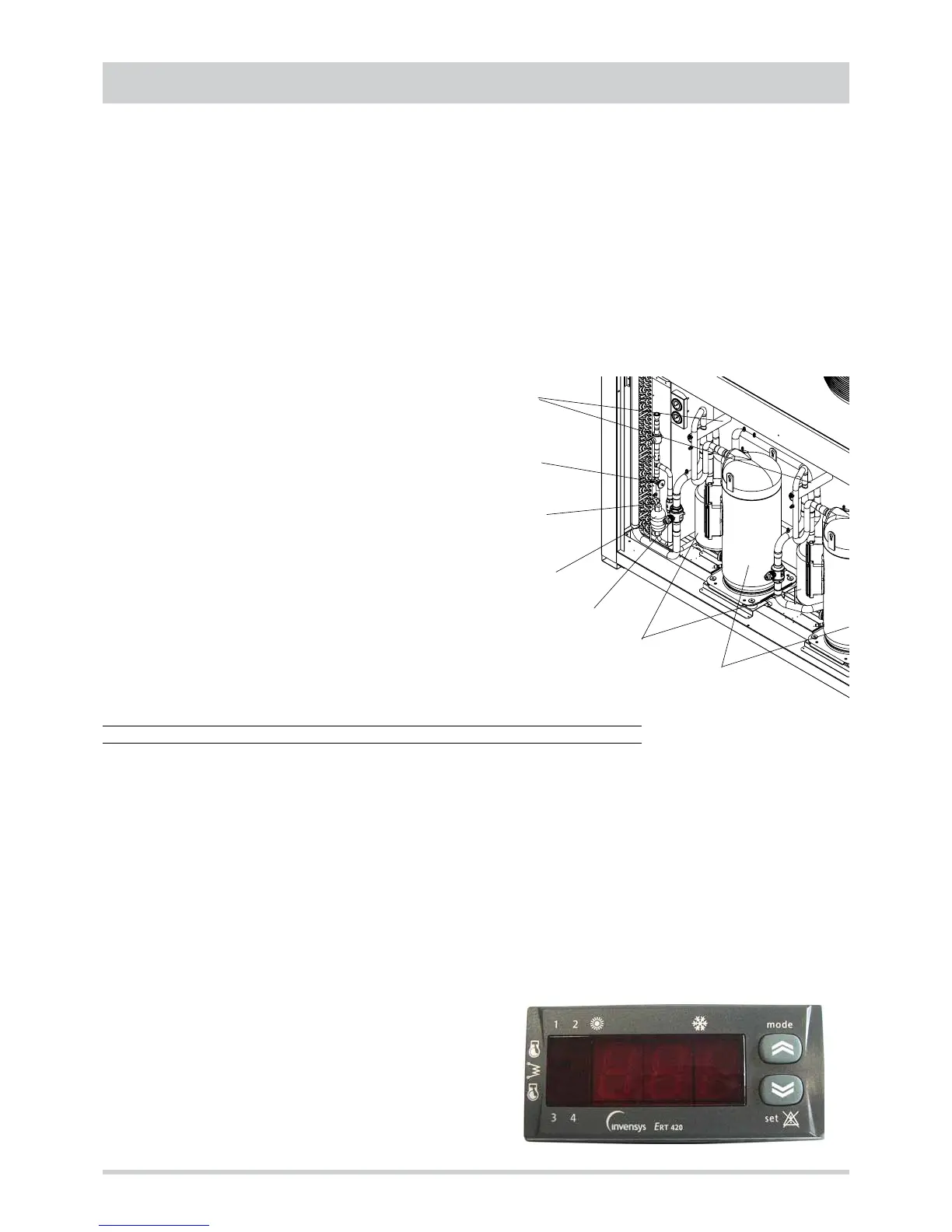

The internal side heat exchanger (user side) (2) is a finned

coil realized with grooved copper pipes and aluminium fins

with notched profile to increase the heat exchange coefficient.

To avoid condensate drag, the frontal crossing air velocity

don't exceed 2,7 m/s, also with the maximum air flow rate

configuration and in the least favourable thermohygrometric

conditions. For the condensate drainage there is a stainless

steel drain tray with inclined bottom, equipped with threaded

connector for the discharge.

The external side heat exchanger (source side) (3) is a

finned coil realized with grooved copper pipes and aluminium

fins with notched profile.

The expansion device (4), a thermostatic expansion valve with

external equalizer , allow the unit to adjust itself to the different

operating conditions keeping steady the set superheating.

The presence in each refrigerant circuit of two valves (one

for the cooling mode and one for the heating mode) allow

to optimize the adjustment of each valve and to obtain the

maximum efficiency.

Each refrigerant circuit contains moreover solid core hermetic

filter dryer (5) to restrain impurity and moisture residuals that

could be present in the circuit, liquid separator (6) placed on

the inlet pipe to protect the compressor against liquid returns,

liquid and humidity indicator (7) to detect the presence of

liquid before each thermostatic valve and allow to verify the

presence of humidity inside the refrigerant, shut off valves

(8) upstream and downstream of each external coil to allow to

stock all the refrigerant inside the coils (pump down) and permit

to execute maintenance operations on the refrigerant circuit

without discharging it, high and low pressure switches in

order to assure the compressor to operate inside the permitted

limits, 4 way reverse cycle valve (9) to allow operating

mode change reversing the refrigerant flow (only heat pump

models) and pressure connections SAE 5/16” - UNF 1/2” -

20 equipped with pin, gasket and blind nut, as required for the

use of R410A refrigerant (they allow the complete check of

the refrigerant circuit: compressor inlet pressure, compressor

outlet pressure and thermostatic valve upstream pressure).

Electrical panel. It contains all the power, control and security

components necessary to guarantee the unit to work properly.

The unit is managed by a microprocessor controller to which all

the electrical loads and the control devices are connected. The

user interface, accessible removing the protection panel of the

electrical board, allow to view and to modify, if necessary, all

the parameters of the unit.

All the units are supplied with an outdoor temperature sensor,

already installed on the unit.

Control system

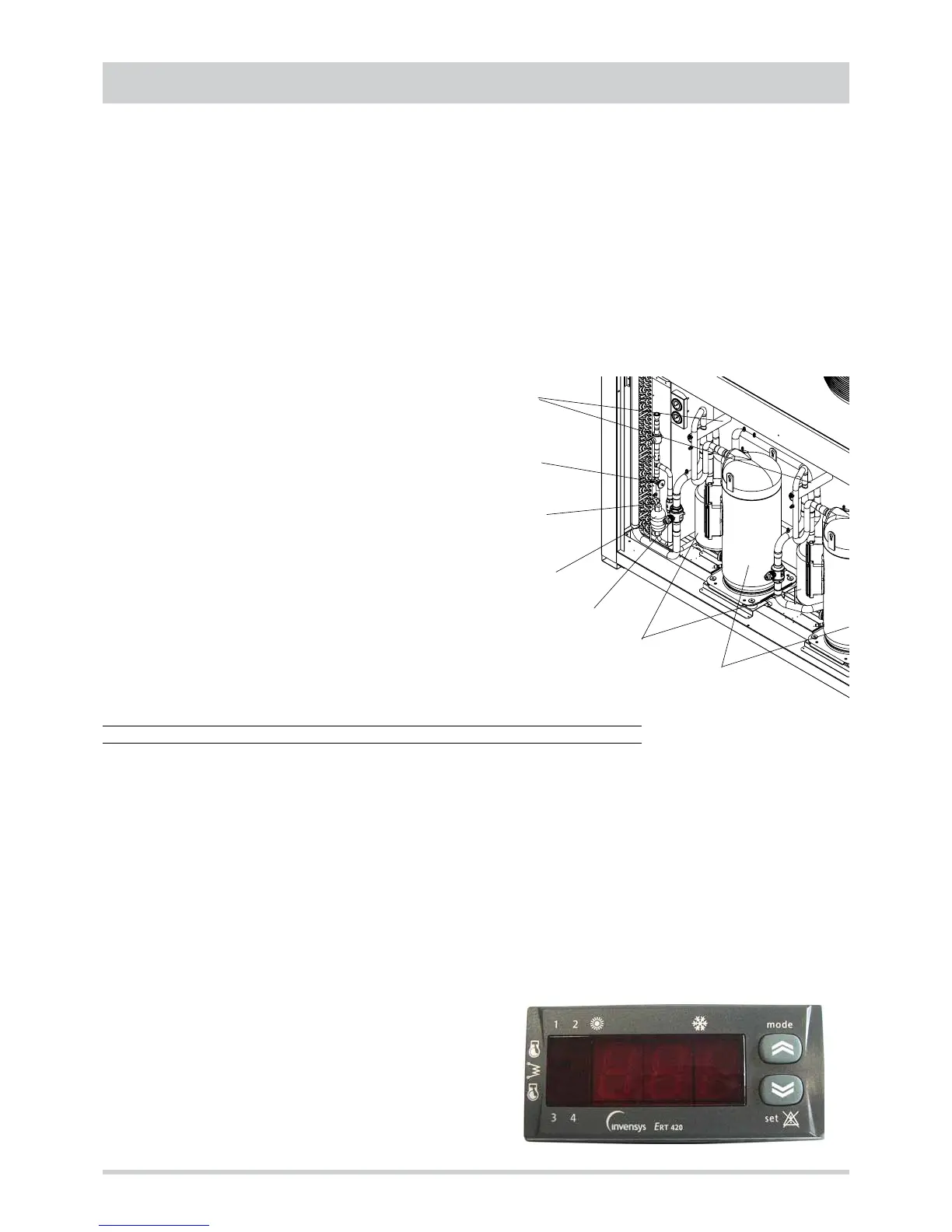

The unit is managed by a microprocessor controller to which,

through a board placed inside the electrical panel, all the

electrical loads and the control devices are connected. The

user interface, accessible removing the protection panel of

the electrical board, is realized by a display and two buttons

that allow to view and, if necessary, modify all the operating

parameters of the unit.

Are available, as accessories, a remote control, that reports all

the functionalities of the user interface placed on the unit, or a

remote thermostat.

The main functions available are :

- treated air temperature management (through set point

adjustment)

- treated air humidity management (only with enthalpic free

cooling option)

- treated air quality management (CO

2

)

- thermal or enthalpic (option) free cooling

- external fan management by means of continuos rotational

speed control (option)

- internal fan management

- return air fan management

- integrative heating sources management (electrical heater

coil, hot water coil, gas heating module)

- defrost cycle management

- dampers management (outdoor air, return air and expulsion

air)

- compressor and internal fan operating hours recording

- serial communication through Modbus protocol

- remote on-off

- remote cooling-heating

- active alarms visualization

- general alarm digital output

6

8

5

4

7

9

Loading...

Loading...