6

GENERAL FEATURES

Description of components

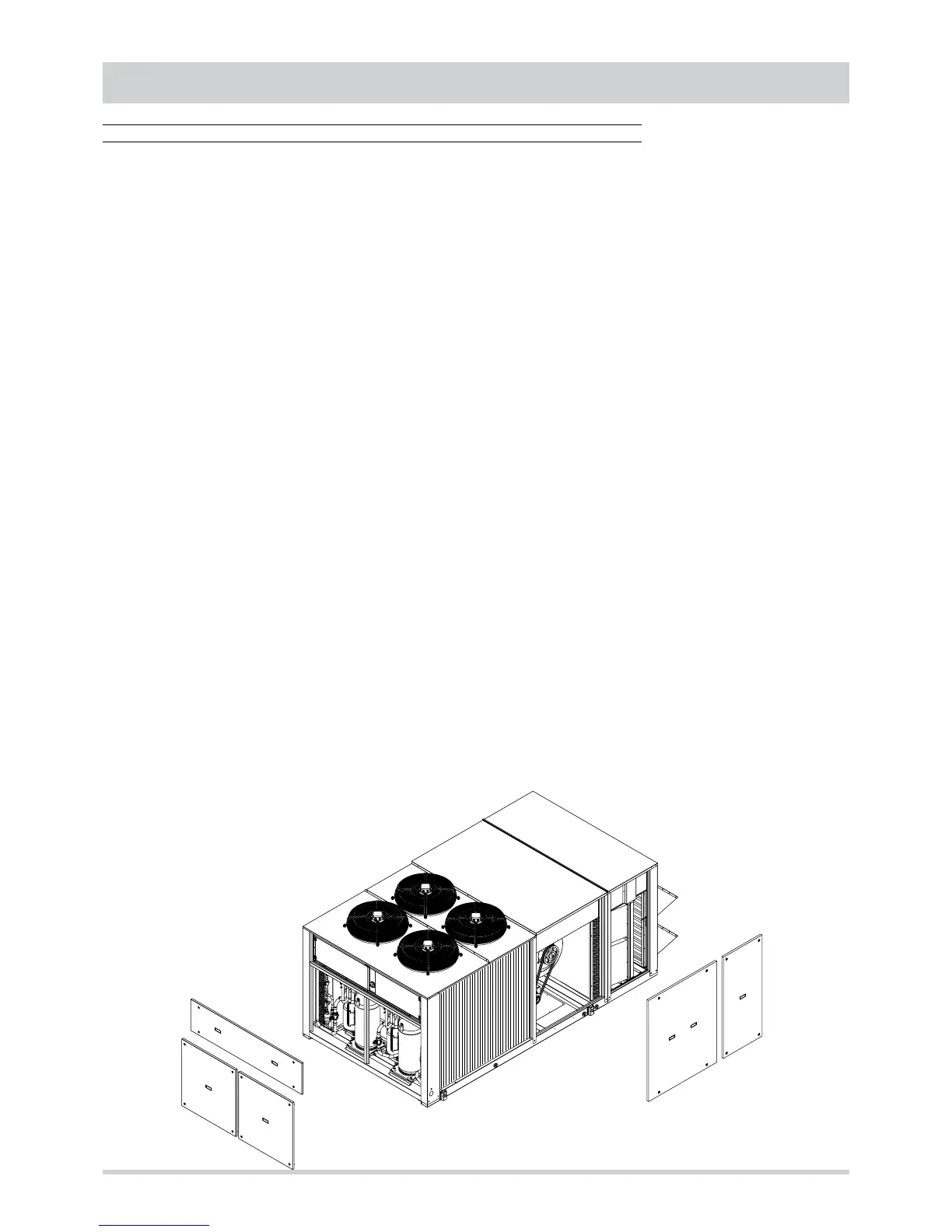

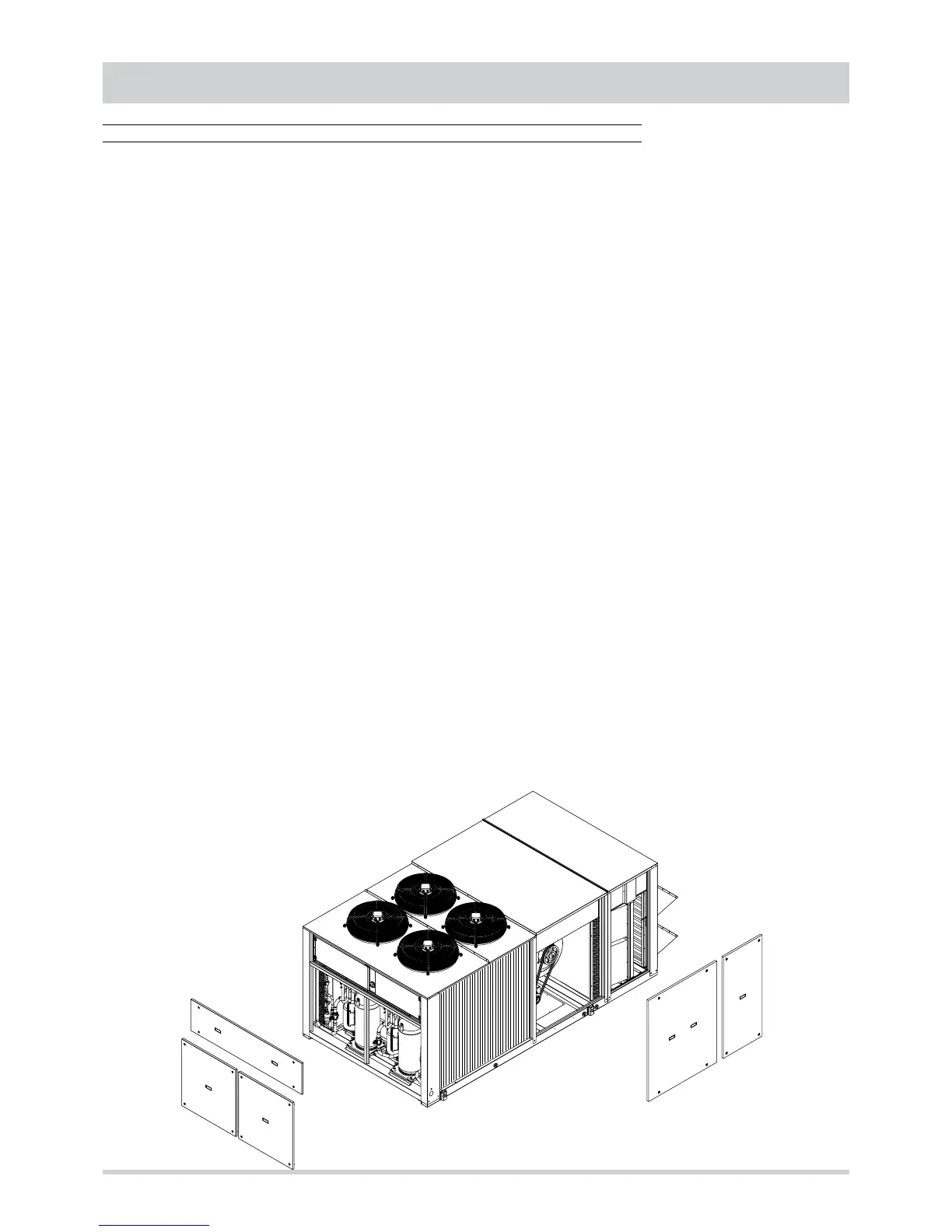

External structure. Basement, supporting structure and

lateral panels are made of galvanized and painted sheet-

steel (colour RAL 7035) to guarantee good resistance to

atmospheric agents.

The inspection panels are all easily removable by means of

¼ turn locks in order to allow total accessibility to the internal

components. The area in contact with the treated air is realized

with galvanized sheet-steel to guarantee proper cleaning and

is externally insulated by means of foam panels and double

panels with interposed an appropriate thermo acoustic

absorber layer in class 1.

External fan section. It is realized by axial fans with alluminium

sickle profiled blades, placed in a galvanized and painted

sheet-steel nozzle, equipped with a safety protection grille and

directly coupled to external rotor motors with intenal thermal

protection. The fans rotational speed is modulated continuosly

by a phase cut device (option) that allow to control the

condensing pressure (in cooling) and the evaporation pressure

(in heating) according to the value read by the temperature

probe placed on the liquid line.

Internal fan section. It is realized by a couple of centrifugal

fans with double aspiration with forward curved blades

balanced both statically and dynamically according to ISO

1940 standards, grade 6.3. The screw, the impeller, and the

frame are realized with galvanized sheet-steel, while the shaft

is made of C40 steel. The fan is coupled by means of belt and

pulleys to a three phase asynchronous 4-poles electrical motor

connected to an appropriate belt tightening slide, with IP55

protection rating, F insulation class, and suitable for continuous

service (S1) with enough heating margins in case of overloads

of limited extent. For powers equal to or greater than 4 kW the

units are equipped as standard with star-delta starter in order

to reduce the starting current and to ensure longer life of the

transmission. The pulley installed on the motor is a variable

diameter type pulley, and allows, within certain limits, to adjust

the rotational speed of the fan to obtain the desired air flow and

available head values.

Return air fan section. It is realized by a couple of centrifugal

fans with double aspiration with forward curved blades

balanced both statically and dynamically according to ISO

1940 standards, grade 6.3. The screw, the impeller, and the

frame are realized with galvanized sheet-steel, while the shaft

is made of C40 steel. For the models of frame 1 and 2 the

fan is directly coupled to a 2 speed electrical motor (star or

delta connection). For the models of frame 3 the fan is coupled

by means of belt and pulleys to an electrical motor connected

to an appropriate belt tightening slide. The pulley installed on

the motor is a variable diameter type pulley, and allows, within

certain limits, to adjust the rotational speed of the fan to obtain

the desired air flow and available head values.

Filtering section. All the units are equipped with waved type

filter cells realized with a galvanized sheet metal frame, an

electrically welded galvanized steel wire protective screen

and a reusable filter element made of polyester fiber stiffened

with synthetic resins. The filter cells have G4 efficiency

class according to standard CEN-EN 779 (Eurovent EU4

classification - 90% average weighted efficiency) and class 1

flame resistance. The filter cells are easily accessible for the

periodic cleaning and inspection operations. Once the advised

final pressure drop has been reached, the synthetic fiber can be

partially reused after treating with warm water and detergents.

Refrigerant circuit. It is contained inside a compartment

separated from the air flow to simplify maintenance and control

operations.

The ermetic scroll compressors (1) are mounted on damper

supports and are protected against overtemperatures and

overcurrents. They are equipped with an electrical heater,

that is activated when the compressor turns off, to keep the

compressor crankcase oil temperature high enough to prevent

migration of refrigerant during winter stops and to evaporate

any liquid present in the crankcase, in order to prevent possible

liquid rushes on starting (only heat pump models).

Loading...

Loading...