56

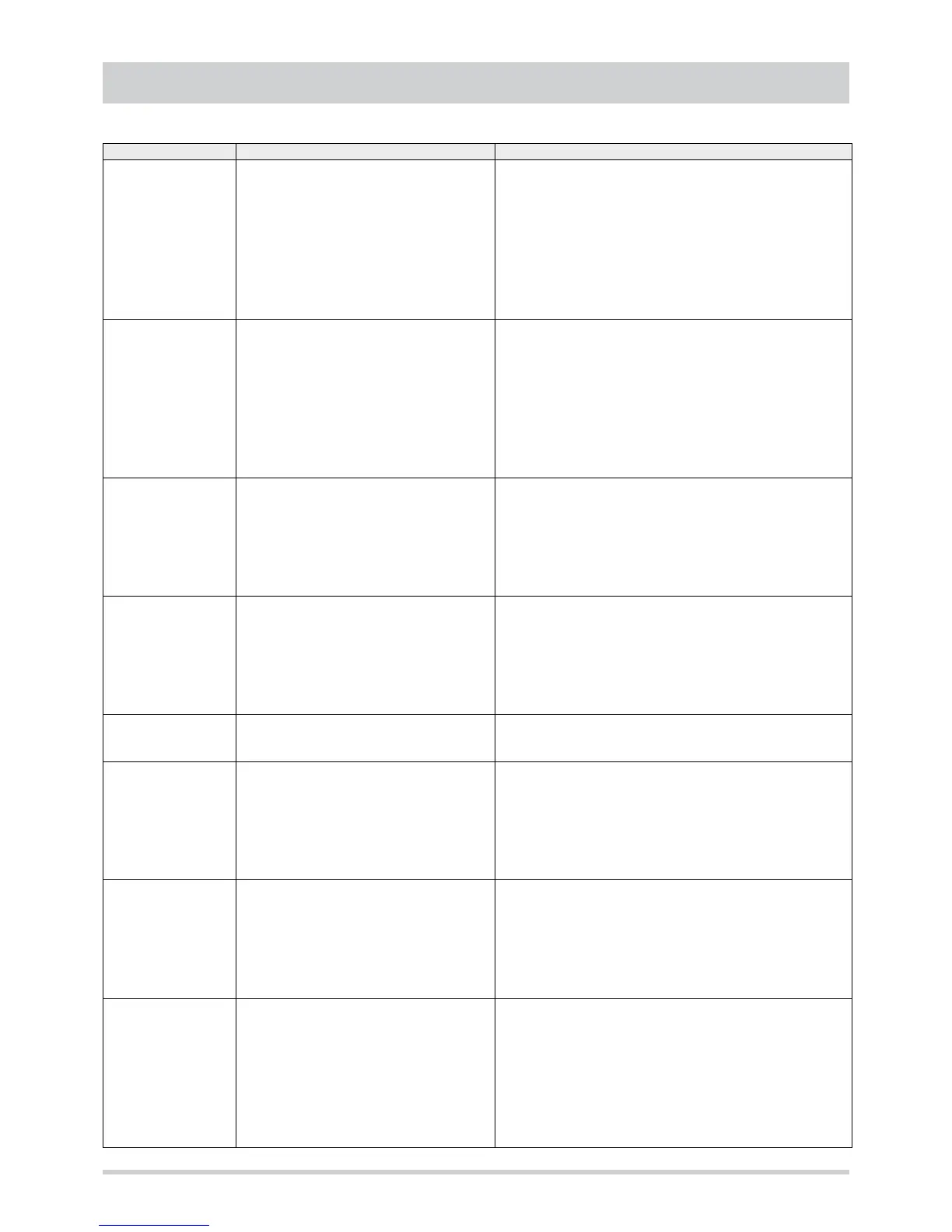

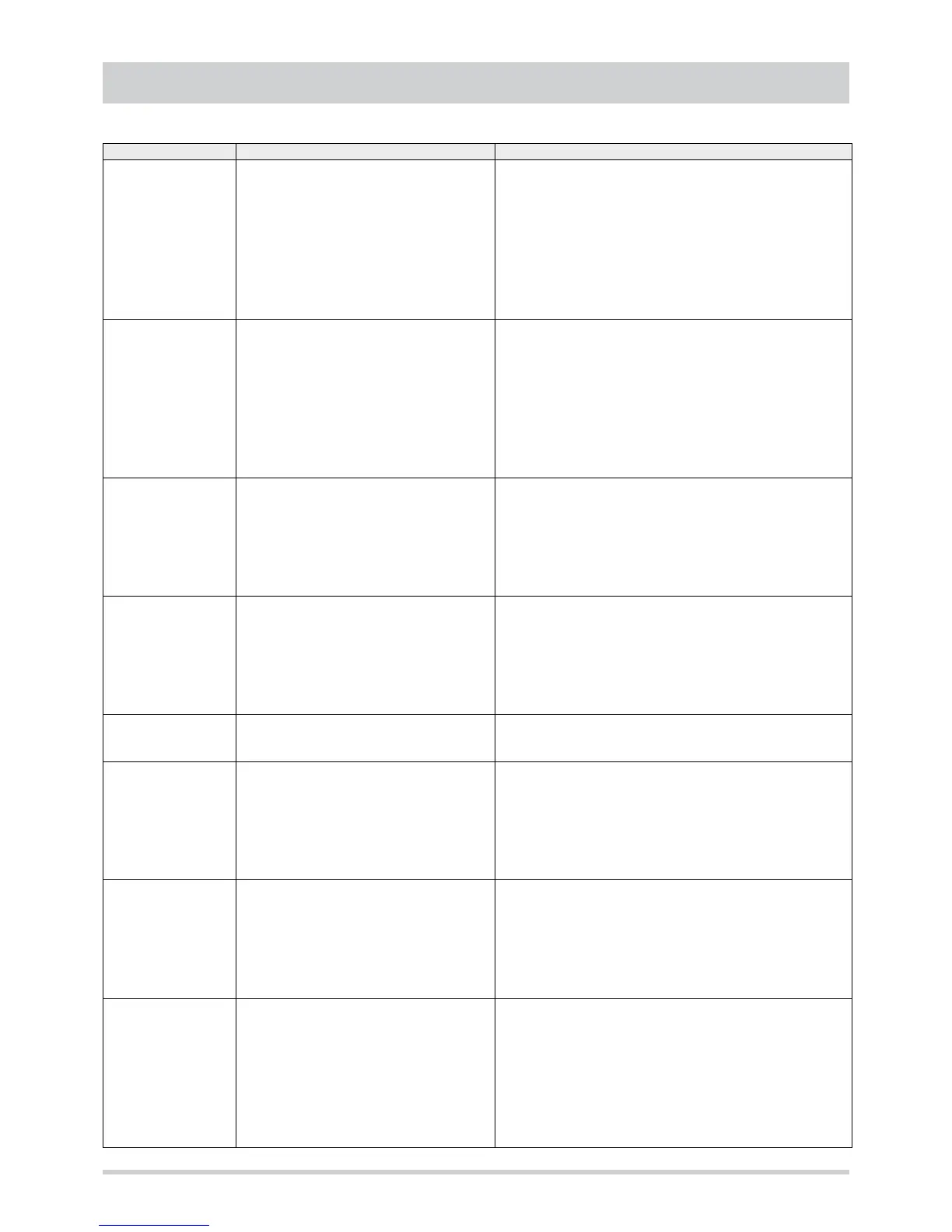

CONTROL SYSTEM

ALARM CAUSE POSSIBLE ACTION OR CHECK

8. External fans faulty (in heating).

9. External fan speed adjustment system inefficient

(in heating).

10. Phase sequence at supply terminals incorrect.

8. Check for any obstructions on the fan blades. Check the electrical

windings and replace any damaged fans.

9. Check the ventilation control PCBs and replace them if necessary.

Check the positioning of the fluid probes and their integrity. Check the

ventilation parameters.

10. Invert two phases at the unit's supply terminals.

The lack of refrigerant in the system is generally caused by leaks. There-

fore the leak points must be identified by pressurising the circuit. Car-

ry out repair, vacuum and reinstate the refrigerant charge necessary

for efficient operation of the unit.

E05

Low outlet air tempe-

rature

IN COOLING

1. Insufficient treated air flow.

IN HEATING

2. Operating temperature outside the operating li-

mits provided for.

3. Excessive opening of outside air shutter.

4. Excessive percentage of renewal air.

1. Make sure the treated air flow is between the max. and min. values

provided for. Make sure the inlet and outlet ducts are open and free

of obstructions. Check the state of the filters for the treated air. Check

the setting of the internal fan transmission and belt tension.

2. Make sure the temperature of the treated air is within the unit's ope-

rating limits.

3. Make sure the outside air shutter is not obstructed or blocked. Check

the operation of the relevant servomotor.

4. Check the shutter minimum opening value (Par L07) and reduce it if

necessary.

E06

Outlet air temperature

probe fault

1. Probe shorted or disconnected.

2. Temperature outside the probe limits (-30°C ÷

90°C).

3. Probe electrical connection faulty or loose.

1. Check the probe as described in the section “Probe characteristics”

and replace it if necessary.

2. With a thermometer check if the temperature is outside the probe

limits.

3. Check the probe electrical connections.If the operating temperature

is correct the probe is not faulty and the alarm remains; the electronic

controller could be damaged.

E07

Fluid probe fault circuit 1

1. Probe shorted or disconnected.

2. Temperature outside the probe limits (-30°C ÷

90°C).

3. Probe electrical connection faulty or loose.

1. Check the probe as described in the section “Probe characteristics”

and replace it if necessary.

2. With a thermometer check if the temperature is outside the probe

limits.

3. Check the probe electrical connections.

If the operating temperature is correct the probe is not faulty and the

alarm remains; the electronic controller could be damaged.

E26

CO2 probe fault

1. Sensor damaged.

2. Electrical connection faulty or loose.

1. Check the instrument and replace it if necessary.

2. Check the probe electrical connections (power supply and output si-

gnal).

E27

Fluid probe fault circuit 2

1. Probe shorted or disconnected.

2. Temperature outside the probe limits (-30°C ÷

90°C).

3. Probe electrical connection faulty or loose.

1. Check the probe as described in the section “Probe characteristics”

and replace it if necessary.

2. With a thermometer check if the temperature is outside the probe

limits.

3. Check the probe electrical connections.

If the operating temperature is correct the probe is not faulty and the

alarm remains; the electronic controller could be damaged.

E40

Inlet air temperature

probe fault

1. Probe shorted or disconnected.

2. Temperature outside the probe limits (-30°C ÷

90°C).

3. Probe electrical connection faulty or loose.

1. Check the probe as described in the section “Probe characteristics”

and replace it if necessary.

2. With a thermometer check if the temperature is outside the probe

limits.

3. Check the probe electrical connections.

If the operating temperature is correct the probe is not faulty and the

alarm remains; the electronic controller could be damaged.

E41

Filters differential pres-

sure switch

1. Dirty filters.

2. Insufficient treated air flow.

3. Electrical connection faulty or loose.

4. Incorrect intervention limit setting.

5. Faulty pressure switch.

1. Check the state of the filters and clean or change them if necessary.

2. Make sure the treated air flow is between the max. and min. values

provided for. Make sure the inlet and outlet ducts are open and free

of obstructions. Check the setting of the internal fan transmission and

belt tension.

3. Check the pressure switch electrical connections.

4. Check the pressure switch setting and make sure the set value is

compatible with the type of filters fitted.

5. Replace the pressure switch.

Loading...

Loading...