4-20

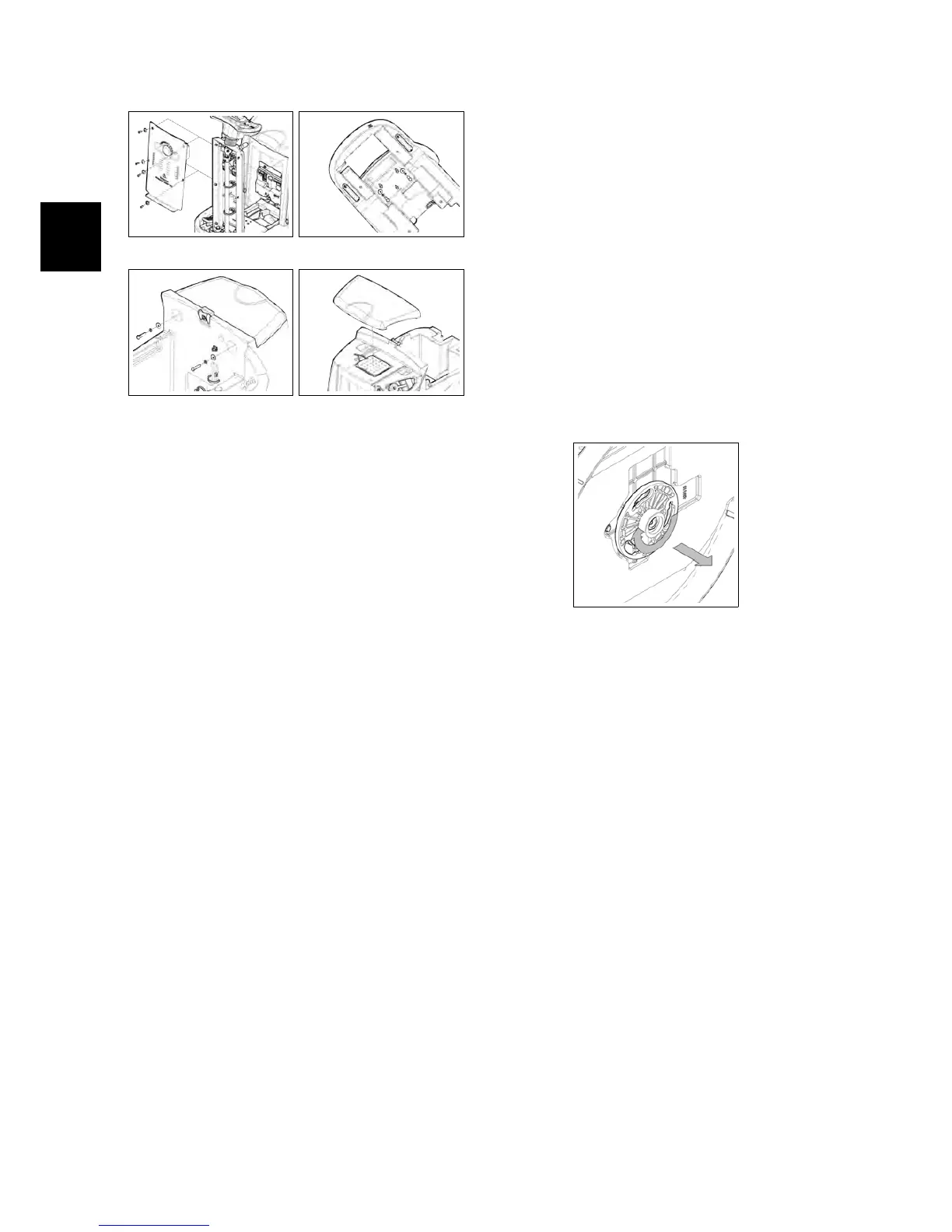

4.1.6-7 4.1.6-8

4.1.6-9 4.1.6-10

4.2 Mechanical Friction

System

4.2.1 Brush Deck Assembly

• Release the brush from the Brush

Deck.

• Put the machine in safe conditions.

• Make sure that the electrobrake is

enabled.

• Lower the brush deck to the floor.

• Remove the lift arms from the frame.

• Disconnect the electrical connector

of the brush motor and the electric

connector of the solenoid valve.

• Disconnect the solution supply

hose.

• Disconnect the lift chain from the

brush plate.

• Lift the front wheel in order to lift the

front part of the machine of about

20cm.

• Pull off the brush deck sideways to

the machine.

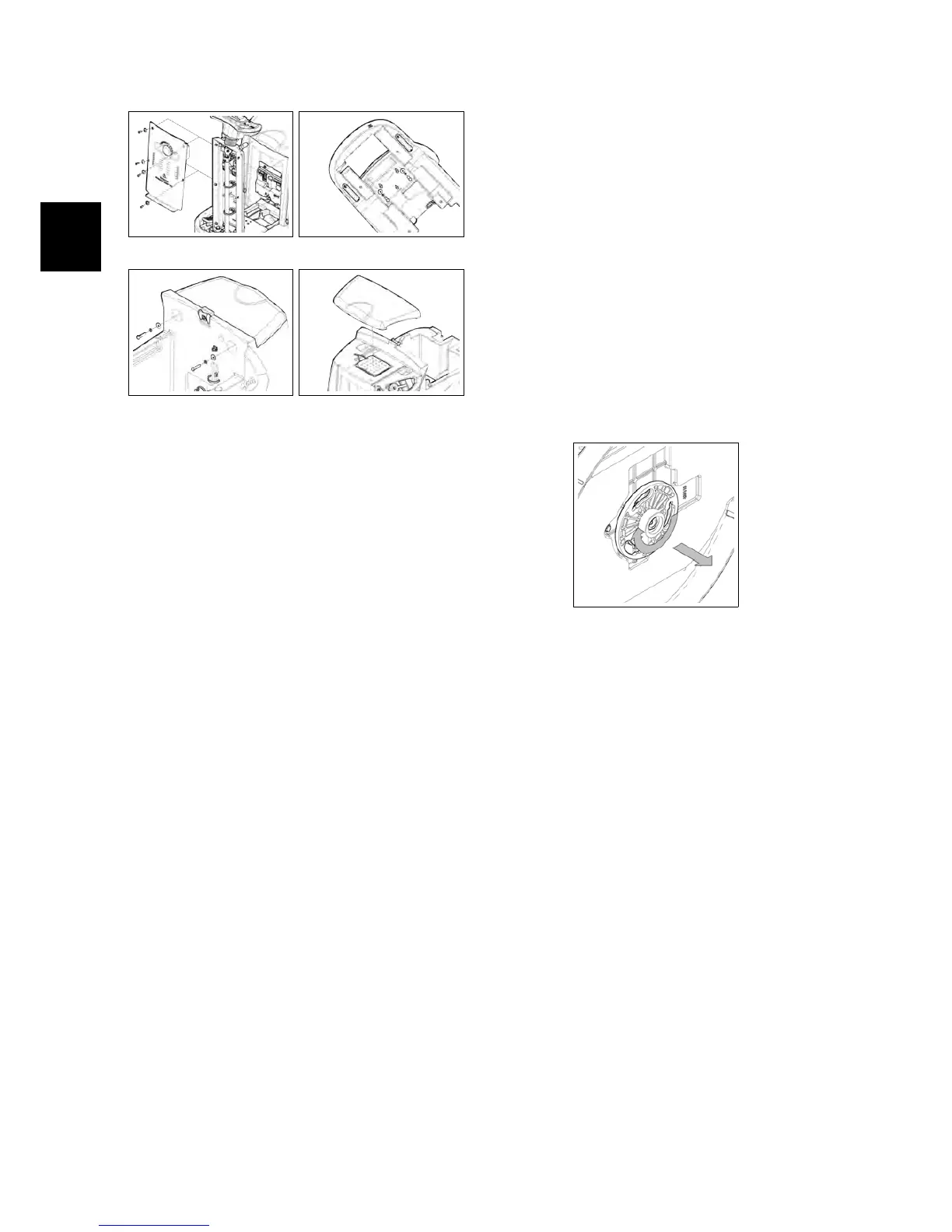

4.2.2 Brush Coupling Flange

• Put the machine in safe conditions.

• Disassemble the Brush Deck from

the machine (see section 4.2.1 at page 20).

• Unscrew the Coupling Flange rotat-

ing it in the same direction as the

brush in standard working condi-

tions.

• Proceed at reverse to refit the part.

Note: Before to refit the part lubricate

the thread in order to prevent blockings

because of dirt or oxide.

4.2.2-11

4.2.3 Brush Motor

• Put the machine in safe conditions.

• Disassemble the Brush Deck from

the machine (see section 4.2.1 at page 20).

• Unscrew the Coupling Flange from

the motor shaft (see section 4.2.2 at page 20).

• Disconnect the electrical connector

of the motor.

• Disconnect the water hose from the

motor (see fig. 4.5.1-58).

• Unscrew the 4 fixing screws and re-

move the motor (see fig. 4.2.3-13).

• Proceed at reverse to refit the part.

Note: Use the thread lock liquid on the

screw during the assembling.

Loading...

Loading...