4-27

• Remove the sprocket fixing screws

(see fig. 4.4.5-49).

• Remove the sprocket.

• Remove the screws that secure the

cam to the sprocket and remove the

cam.

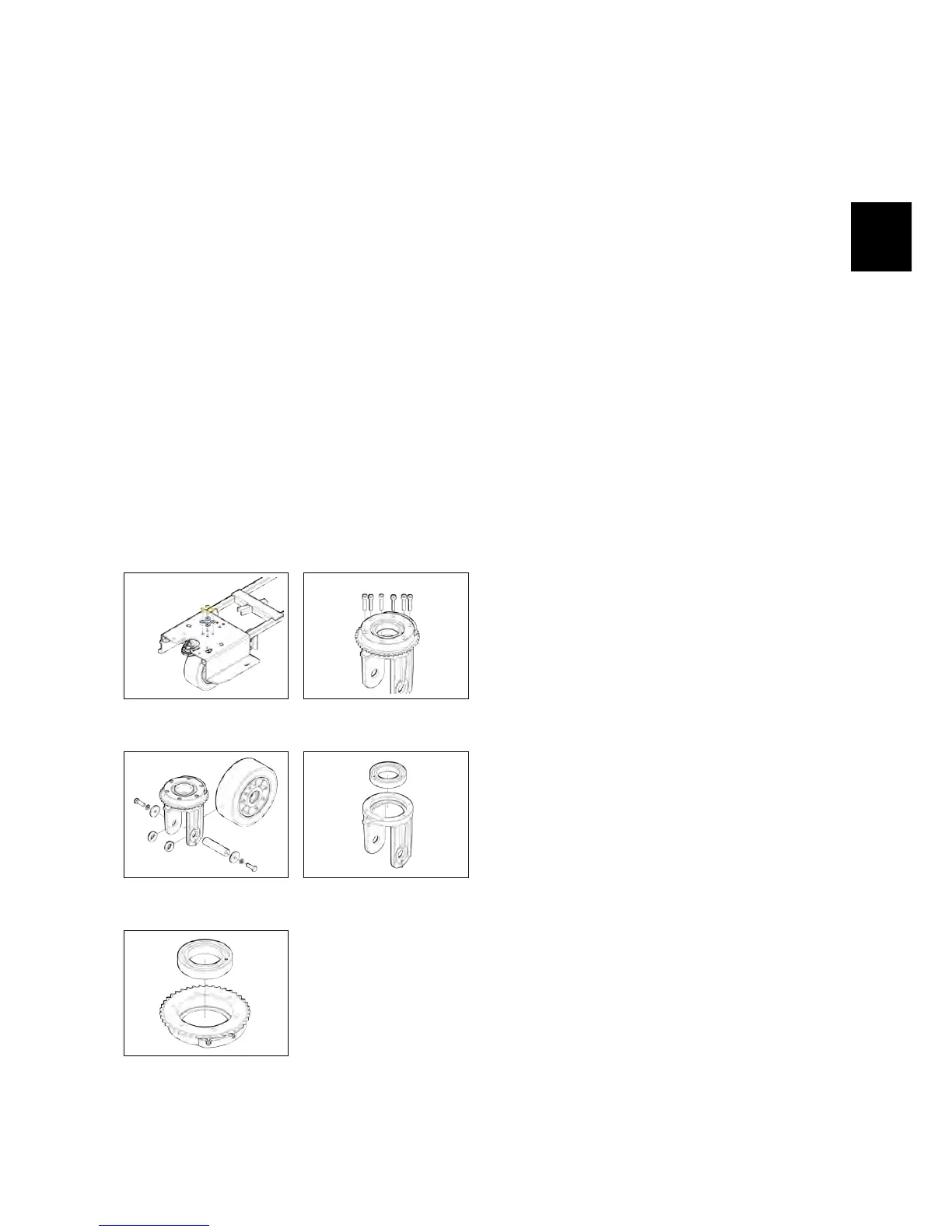

• Remove the Front Wheel (see fig. 4.4.5-

50).

• Remove the bearings pin.

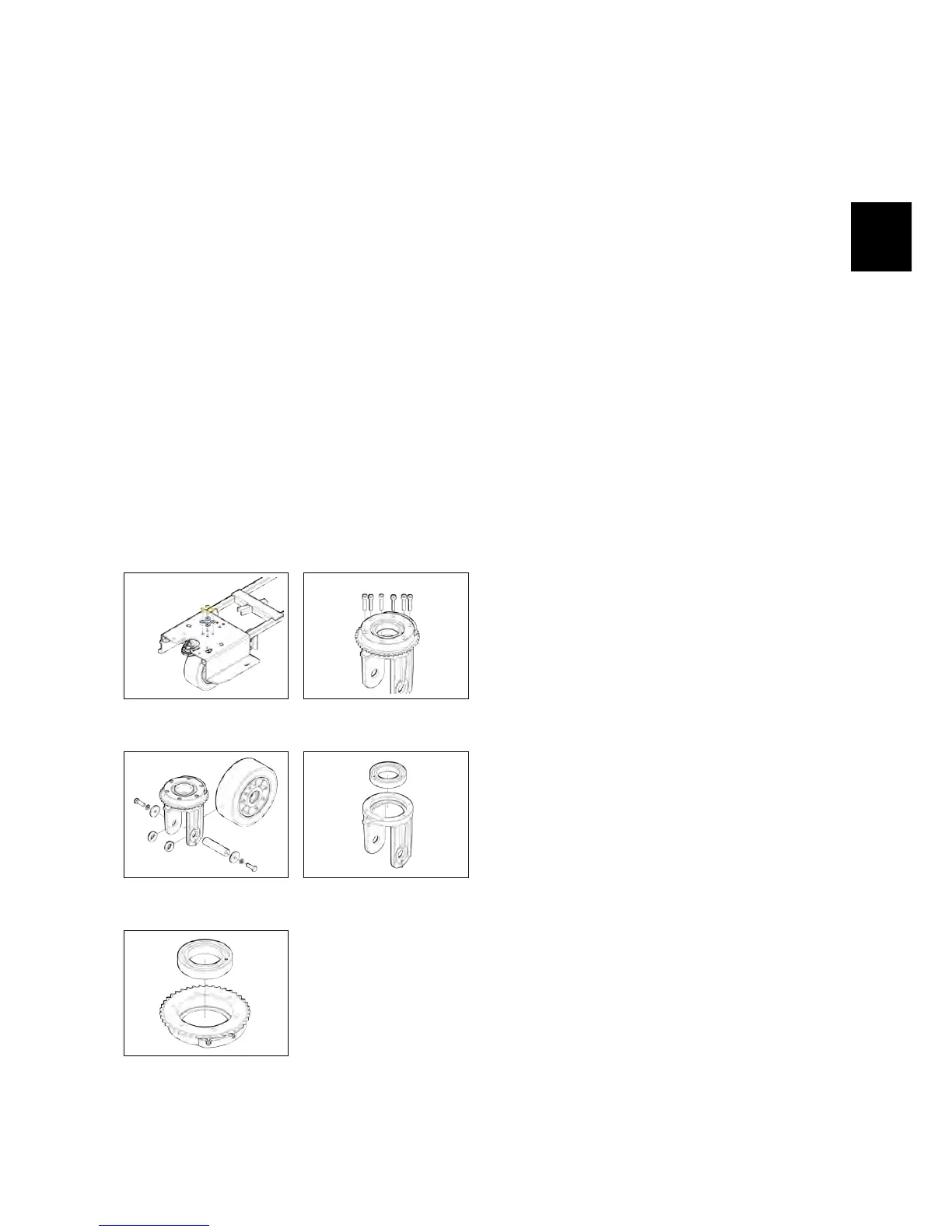

• Remove the bearings (see fig. 4.4.5-52).

• Proceed at reverse to refit the part.

ATTENTION: WHEN ASSEMBLING, PAY

EXTREME ATTENTION AT THE CORRECT

POSITIONING OF THE SPACER 436224,

BECAUSE IT IS FUNDAMENTAL FOR THE

PROPER FUNCTIONING OF THE PAR T.

4.4.5-48 Fixing screws of

the wheel to the frame

4.4.5-49 Fixing screws of

the steering sprocket

4.4.5-50 Wheel support

pin

4.4.5-51 Bearings in the

wheel fork

4.4.5-52 Bearings on the

steering sprocket

4.5 Solution Delivery Sys-

tem

4.5.1 Solution Tank

• Put the machine in safe conditions.

• Remove the recovery tank (see section

4.3.4 at page 23) (see fig. 4.5.1-53).

• Remove the battery tray (see fig. 4.5.1-54).

• Remove the steering column

carter.(see fig. 4.5.1-55).

• Remove the footrest.

• Remove the electrical installation

carter (see fig. 4.5.1-56).

• Remove the support bracket of the

Main card.

• Remove the traction pedal assembly.

• Remove the seat and the deadman

microswitch (see fig. 4.5.1-57).

• Disconnect the water hose from the

brush deck (see fig. 4.5.1-58).

• Disconnect the control rod from the

water valve (see fig. 4.5.3-62).

• Remove the screws that secure the

solution tank to the machine frame.

• Remove the tank, pulling it out from

the steering column, taking care not

to damage the steering wheel.

• Turn the tank and remove the solu-

tion delivery system (see fig. 4.5.1-60).

• Proceed at reverse to refit the part.

4.5.2 Hoses

• Put the machine in safe conditions.

• Loosen the clamps that hold the

hose to the fitting.

Loading...

Loading...