Commissioning Multi-DENCO

112 FläktGroup DC-2013-0101-GB • Subject to modifications • R5-08/2020

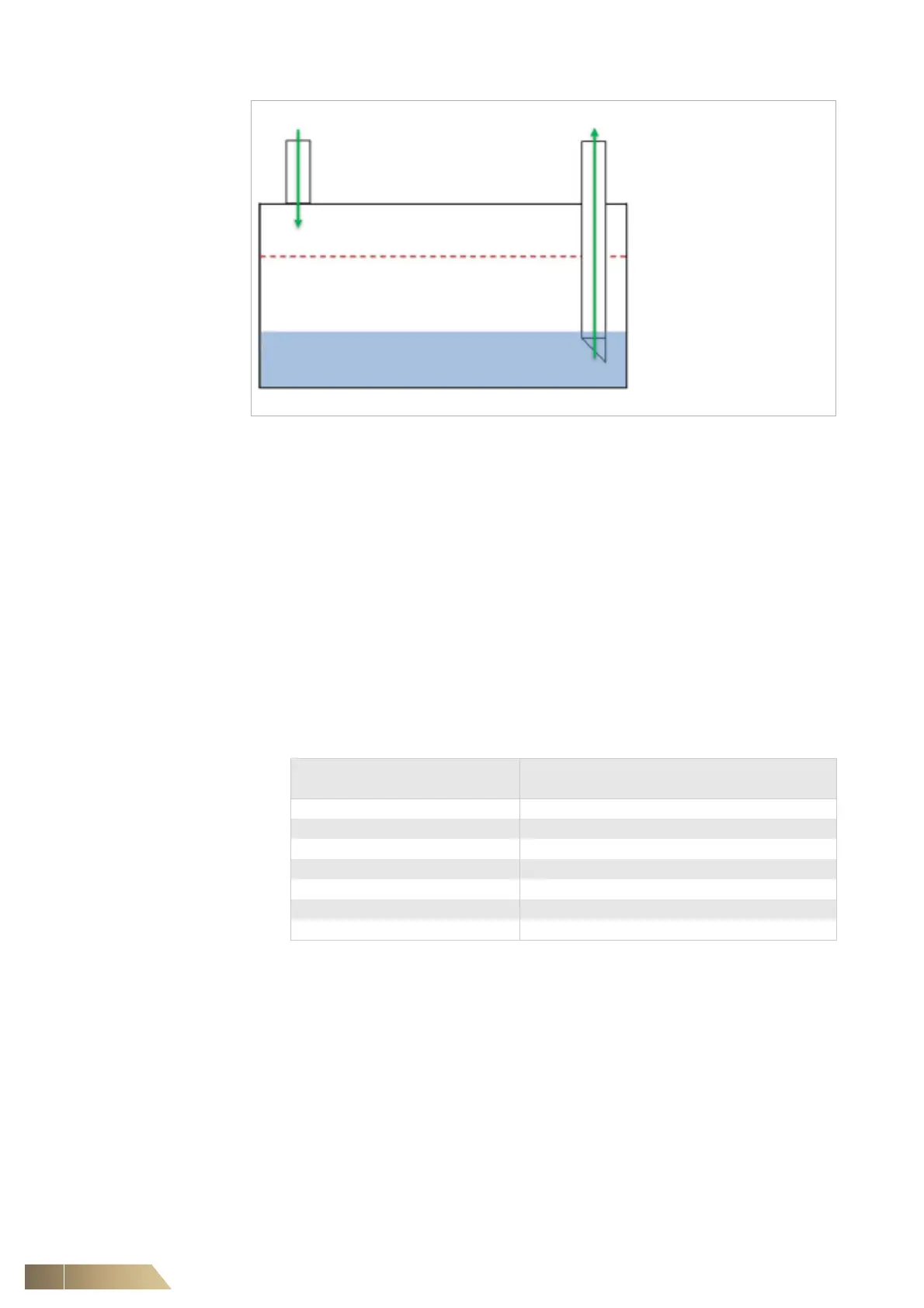

Fig. 8-2

• Add ALL the remaining estimated refrigerant to the system to fill the liquid

receiver further.

6. Once all the refrigerant has been added, the liquid receiver needs to be checked.

• Measure the ambient temperature on the face of the condenser coil.

• Take several measurements at different positions and calculate an

average value.

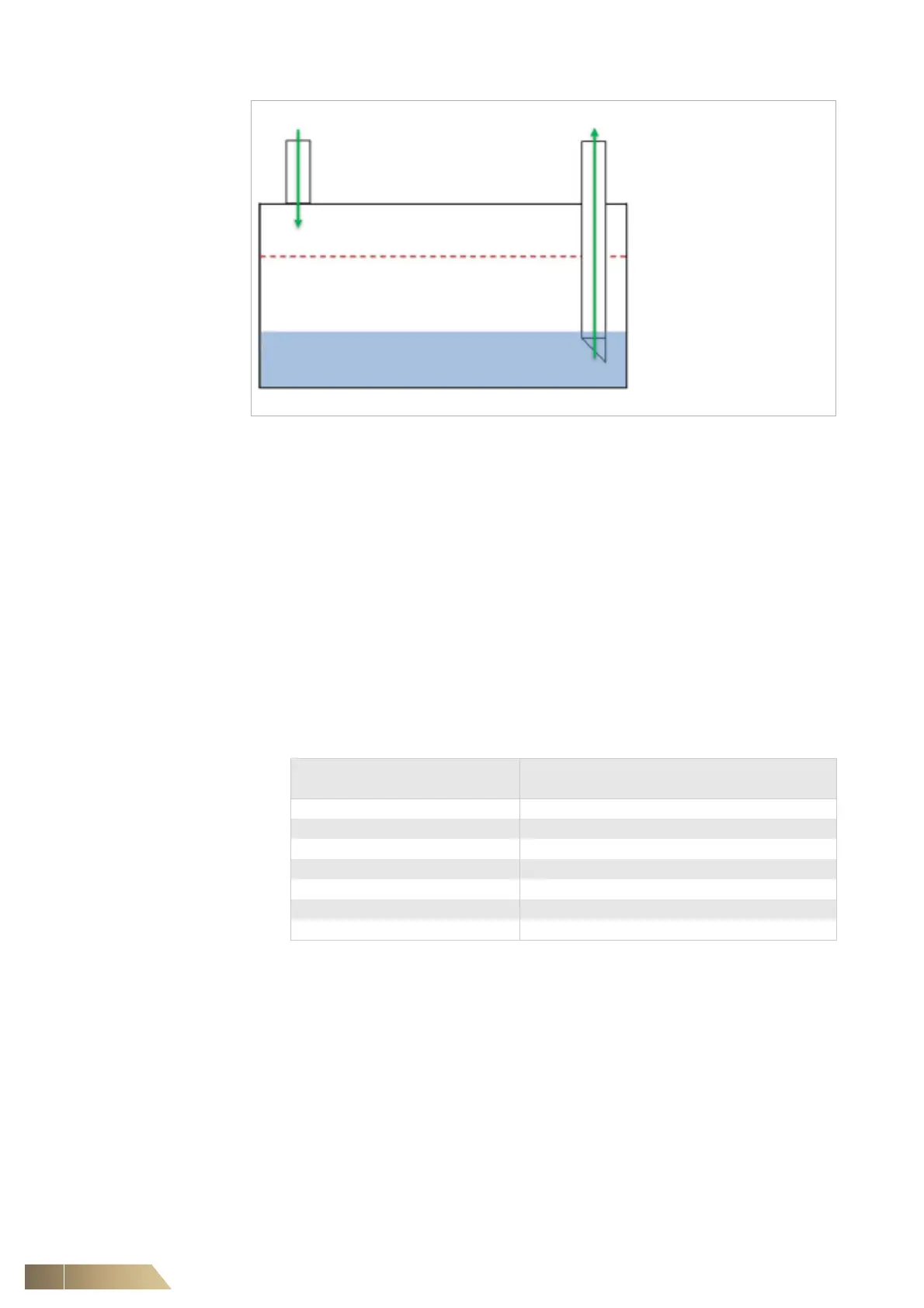

• Using the average temperature, the level of the liquid receiver should match

Tab. 8-5

• For example; if the temperature is above 20°C, the liquid receiver should only be

80% full (no liquid refrigerant in the condenser coil)

• Otherwise; if ambient temperature is 0°C on the day of commissioning, then the

liquid receiver should be about 30% full (lots of liquid refrigerant in the condenser

coil)

• Using a touch probe on the receiver shell (under the insulation) measure every

5 to 10 mm to determine the liquid receiver fill level.

• If the level does not match, add/remove refrigerant to meet the values in

the table.

7. Once the refrigerant level is correct, perform standard calibration checking (chapter

8.3.4).

8. The condenser fan settings should then be restored to 24 Bar and left on 'Minimum

Speed' control.

Level when 'liquid flashes' are

observed.

Required level

Ambient Temperature

°C

Liquid Receiver Fill Level

%

30 80

20 80

10 50

0 30

-10 20

-20 15

-30 10

Tab. 8-5

Loading...

Loading...