Multi-DENCO Medium Connections

FläktGroup DC-2013-0101-GB • Subject to modifications • R5-08/2020 61

6.2.2 Material quality

For refrigeration pipework:

– Copper tube quality must be the equivalent of EN 12735-1

– Refrigeration grade copper must be used

– Pipework must be cleaned and dehydrated

– Use of joints, bends or sets must be kept to a minimum

– Bends or sets are to be machine pulled to approved radius at all times

– Only properly swaged joints can be used (butt joints are not allowed)

– Manufactured bends are not recommended

– It is recommended to use half-hard straight lengths of copper instead of coils.

6.2.3 Sizing

Pipe sizing When sizing pipework, consideration should be given with regards to adequate oil

return during all conditions.

It is also important that the pressure drops in pipework are minimised to avoid unnec-

essary decreases in capacity. Larger pipe sizes reduce gas velocity and make oil

return more difficult to accomplish. Smaller pipe diameters increase oil velocity, but will

be more susceptible to high pressure drops.

A-Version & F-Version

Discharge Line: Recommended pressure drop = 1.0K, Max pressure drop = 2.5K

Liquid Line: Max pressure drop = 1.5K

NOTE!

Prior to installation it is particularly important to check the correct size refrigeration

pipework is being installed. Contact your local representative if you are unsure.

NOTE!

Only the pipe sizes listed below are ALLOWABLE for each size. ONLY these sizes

MUST be used for both horizontal and vertical risers. This table is for REFERENCE

ONLY.

NOTE!

FINAL and ULTIMATE responsibility for pipe sizing is of the contractor or installer.

The below table is for GUIDANCE ONLY to specify the range of sizes applicable. It

is necessary that suitably qualified engineers conduct their own, separate calcula-

tions to determine the sizing suitable for the application.

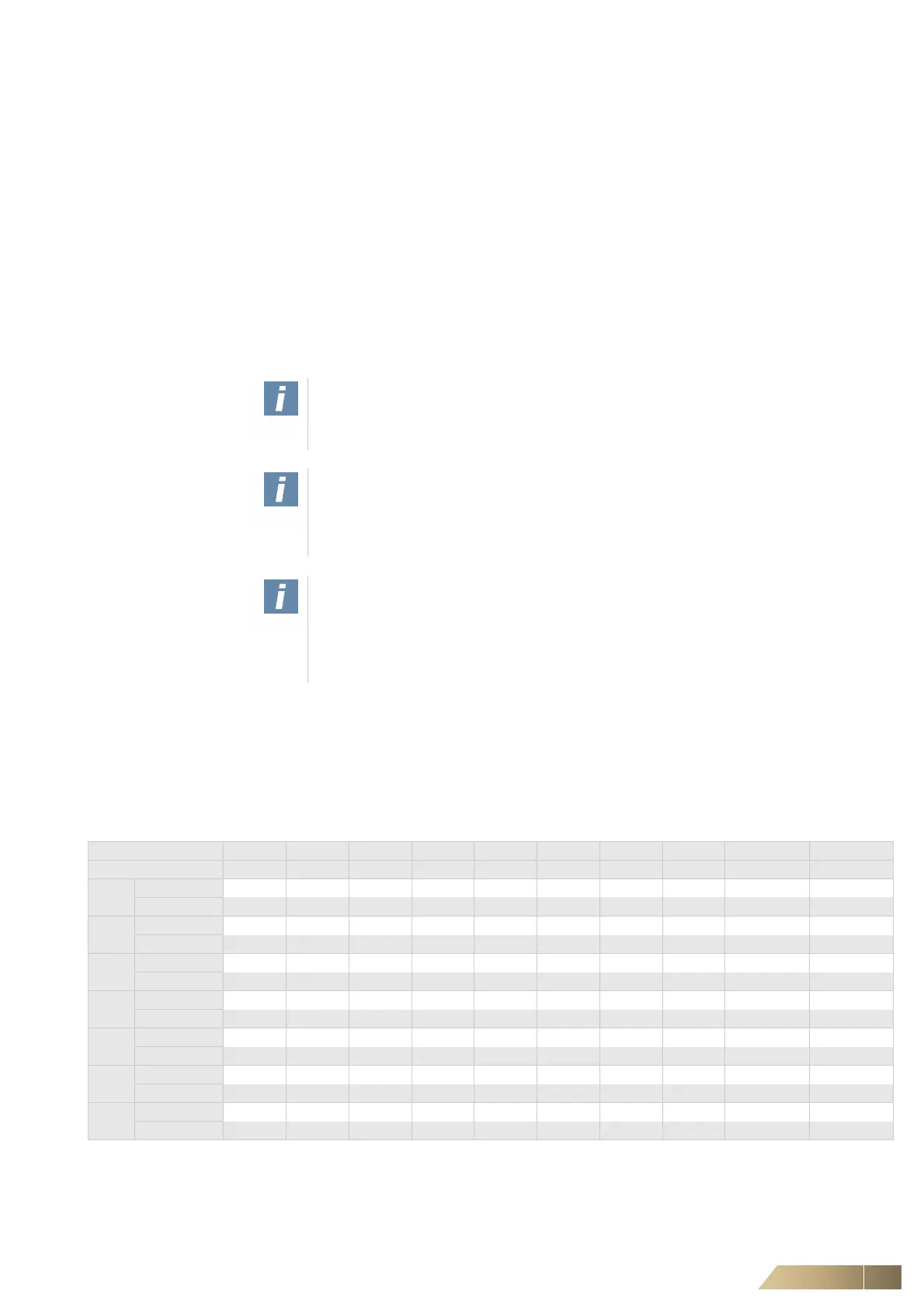

Metric (mm) 10 12 16 18 22 28 35 42 2 x 22 2 x 28

Imperial (Inch) 3/8 1/2 5/8 3/4 7/8 1-1/8 1-3/8 1-5/8 2 x 7/8 2 x 1-1/8

010

Liquid zzzz

Discharge z z z

018

Liquid zzz

Discharge z z

030

Liquid zzz

Discharge z z z

045

Liquid zzz

Discharge z z z

065

Liquid zz

Discharge z z

092

Liquid zz

Discharge z z z

130

Liquid z

z

Discharge

z

z z

Tab. 6-1

Loading...

Loading...