32

ARPEX 8706 en

Operating instructions 10/2017

4 35512

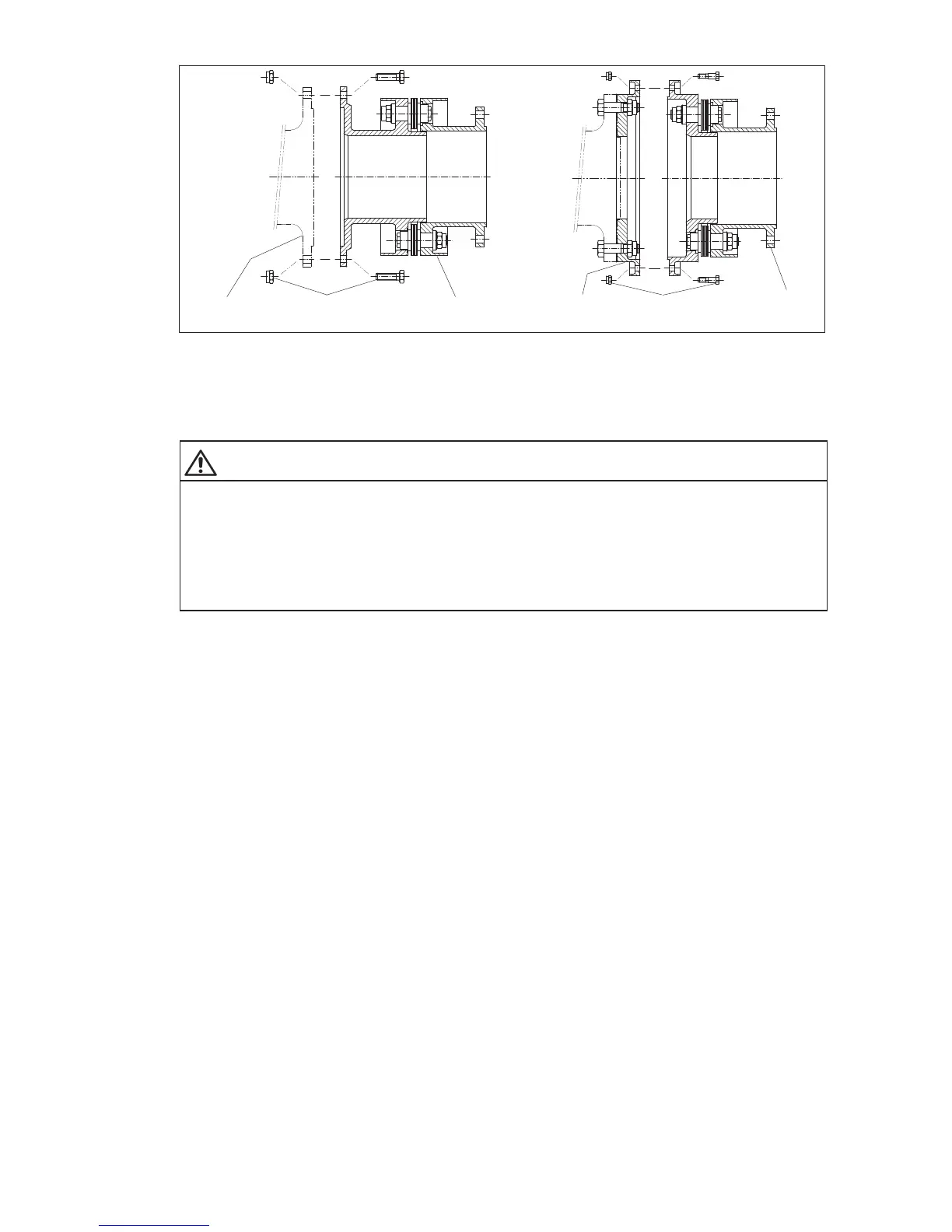

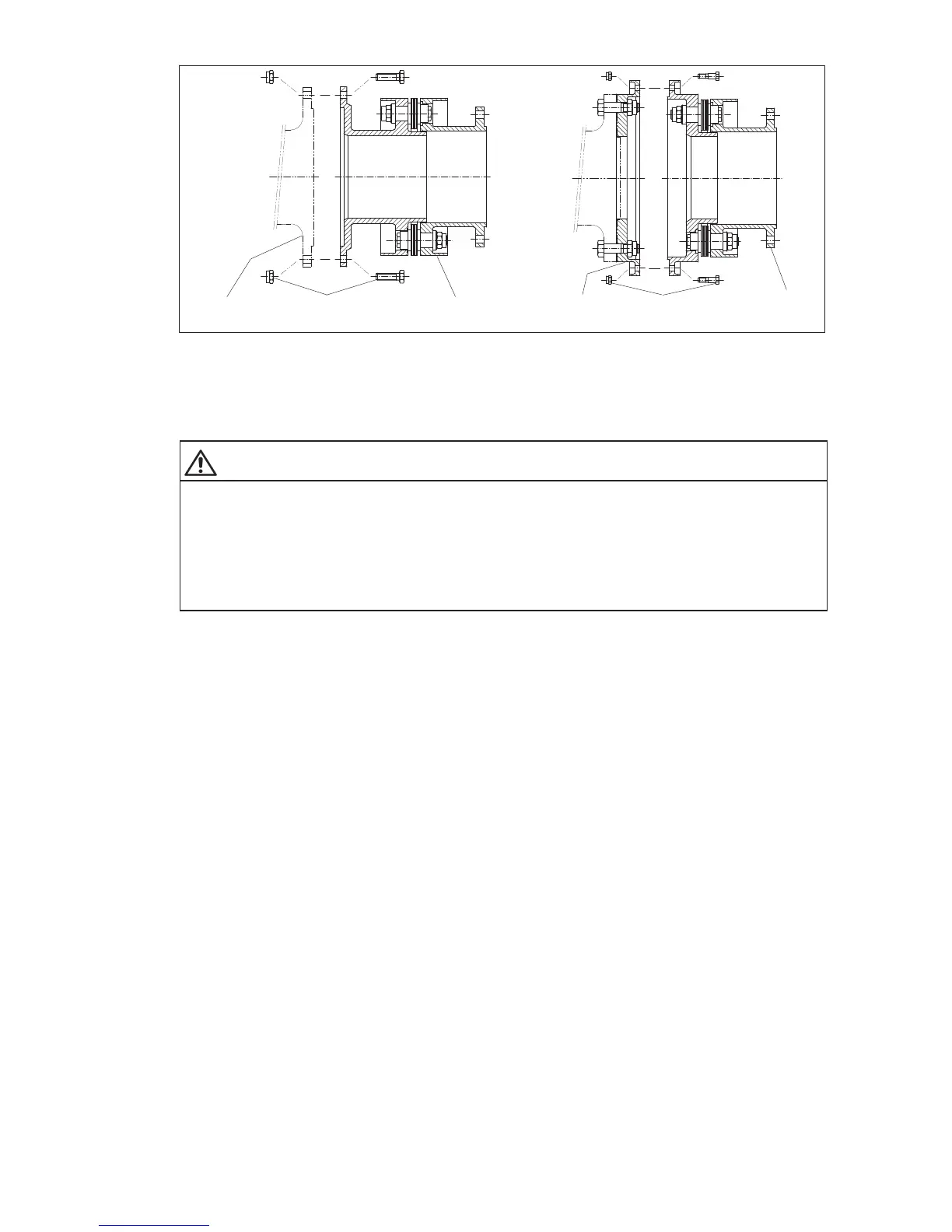

Fig. 22: Fitting "F" and "D" modules

1"D" module 2 "F" flange (fitted)

3"F" module 4 Connecting flange

5 Screw connection of flange

WARNING

Risk of serious injury through flying fragments

Risk of serious injury through flying fragments and/or risk of damage to the coupling.

– Locking nuts must only be used three times, to guarantee the locking properties.

– Adhere to specified tightening torques. Observe the instructions relating to cleaning and/or treatment

of the bolts with auxiliary materials.

6.5 Test run of the customer’s shaft with fitted coupling parts

Observe the safety instructions in section 6.1, "General information on fitting"!

If a test run of the customer’s shaft with fitted coupling parts and any weight simulators must be performed,

if necessary, this should be done in accordance with the configuration described in item 6.10.

6.6 Compensation of the flange or shaft distance "DBSE"

Observe the safety instructions in section 6.1, "General information on fitting"!

"DBSE" = distance between shaft ends

Set the flange or shaft distance between the machines to be coupled exactly to the fitting

dimension "DBSE" (on axially pretensioned couplings "DBSE fitting"), as shown on the orderspecific

drawing of the coupling.

Lengths can be adjusted with shims. These are mainly used with tapering shaft ends and customer’s

connecting flanges. Shims form only an optional part of the scope of delivery. The position of the shims can

be seen on the orderspecific drawing of the coupling. As a rule, they are fitted between the fitted

coupling part (e.g. "M"hub or "B" module, see figure 23) and the intermediate unit (e.g. "H" module or

"V" spacer, see figure 23). With customer’s connecting flanges they can also be fitted between the fitted

coupling part (e.g. "F" flange, see figure 23) and the customer’s flange.

Loading...

Loading...