26

OPERATION (continued)

USER CONFIGURATION MODE (Advanced Options) (continued)

DAUGHTER BOARD MODULES (continued)

4-20mA Menu (Requires 4-20mA Daughter Board Module) (continued)

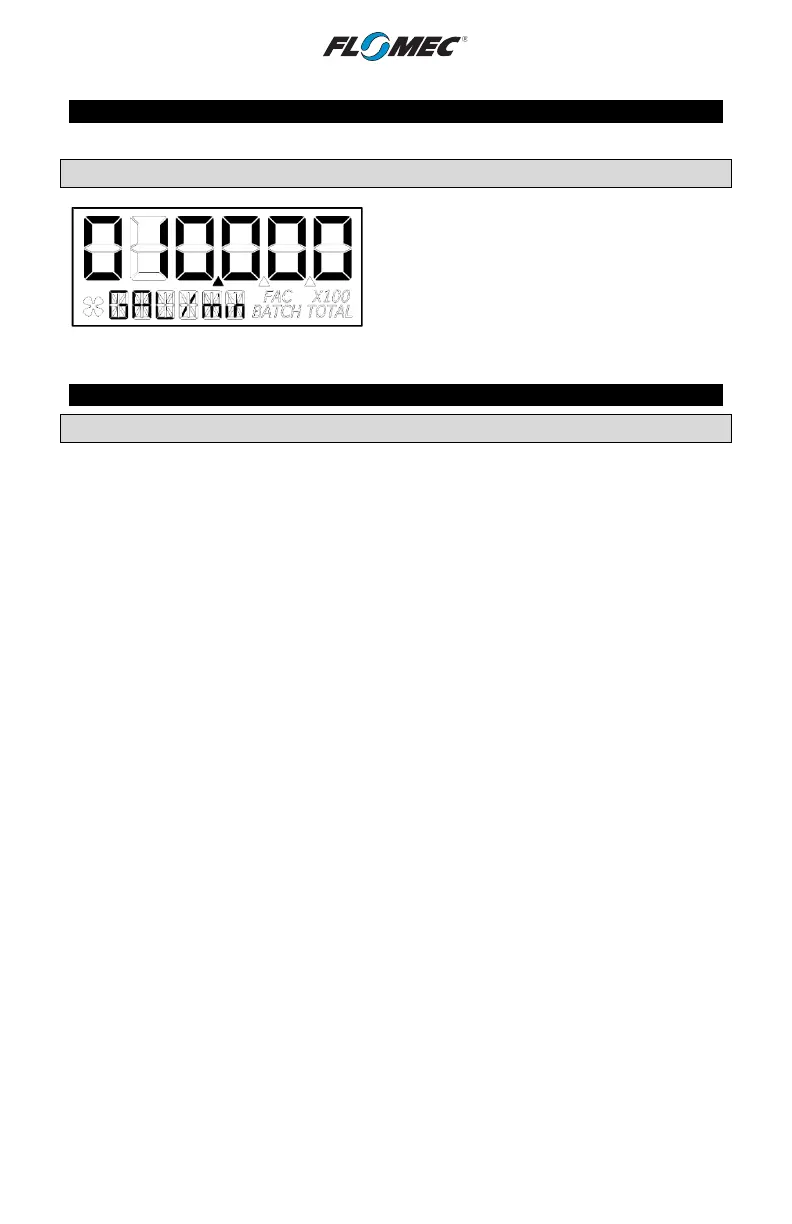

NOTE: Figure 29-4 shows the display when

changing “span” or 20mA Flowrate Settings.

Figure 29-4

USER CONFIGURATION MODE (Field Calibration Mode)

Field Calibration Method

General

The field calibration method may be set by the user, and can be changed or modified at any

time using a field calibration method described in this section. Totals or flowrate derived from

the field calibration are being invoked when the (FAC) icon is no longer visible below the 6-

digit display.

Factory calibration settings are programmed into each computer during manufacturing, using

Stoddard test solvent at 70° F (21° C) for meters up to 1 inch. Meters 1-1/2 inch and larger

are factory calibrated using water at 70° F (21° C).

Settings are correct for light liquids such as water, gasoline or diesel. Readings using the

factory calibration (FAC) may not be accurate in some situations, for example, "heavy" liquids

such as motor oil, under extreme temperature conditions, non-standard plumbing

configurations or with fluids other than those mentioned above.

For improved accuracy under such conditions, the computer allows for field calibration, that

is, user entry of custom calibration parameters. A "single point" field calibration curve may

yield acceptable accuracy when used in a non-standard application; however, the computer

is capable of programming a “five point” field calibration curve.

NOTE: If the calibration method is changed when in user configuration mode, i.e., not using

the default factory calibration (FAC), the programming will allow the user to adjust the user

programmable calibration table for the calibration method selected. This is done by shunting

the user to the field calibration method entry menu specific to that calibration method upon

exit from the user configuration mode.

Verify Accuracy before Beginning Field Calibration

For the most accurate results, dispense at a flowrate which best simulates your actual

operating conditions. Avoid "dribbling" more fluid or repeatedly starting and stopping the flow.

This can result in less accurate calibrations. Make sure you meet the meter's minimum

flowrate requirements.

The use of a uniformly dependable, accurate calibration container is recommended for the

most accurate results. A five-gallon calibration container is available in the parts section of

this manual. For best results, the meter should be installed and purged of air before field

calibration.

Due to high flowrates on meters 2 inch and larger, it is strongly recommended that field

calibration be completed with a combination of volume and weight determined with fine

resolution scales.

Loading...

Loading...