32

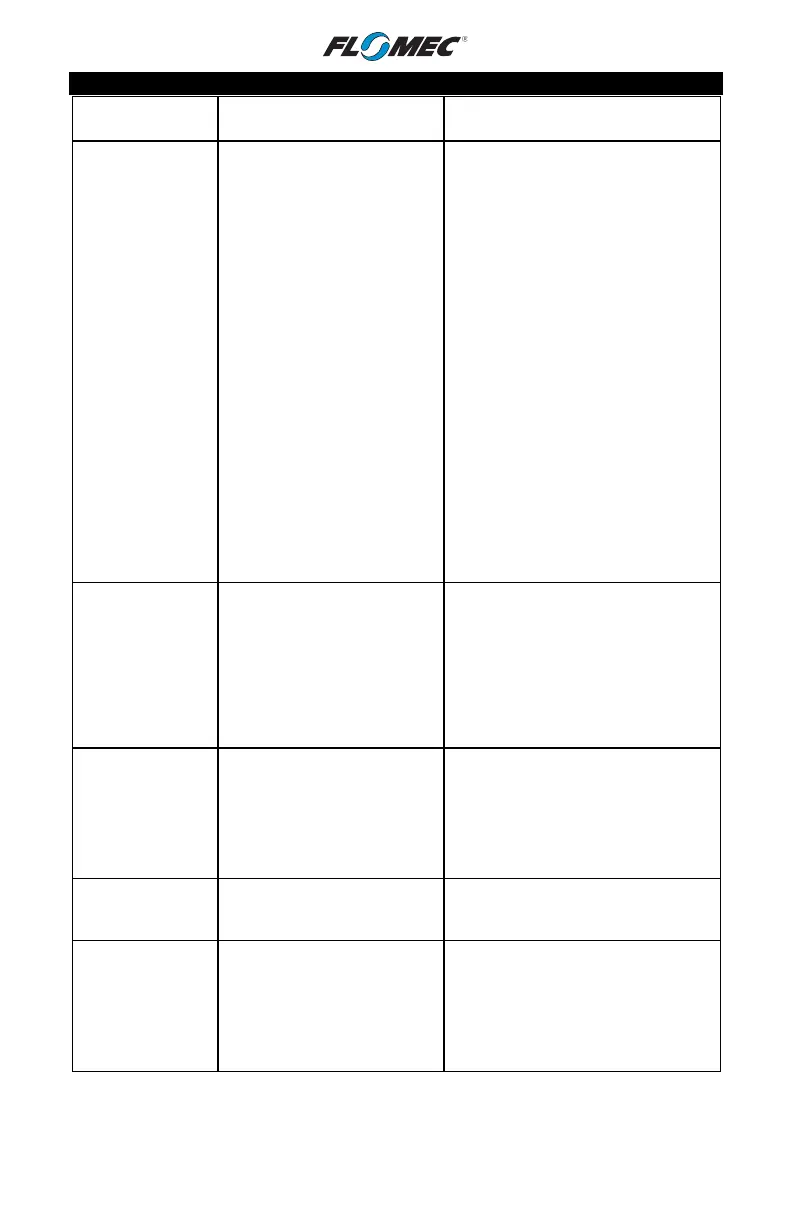

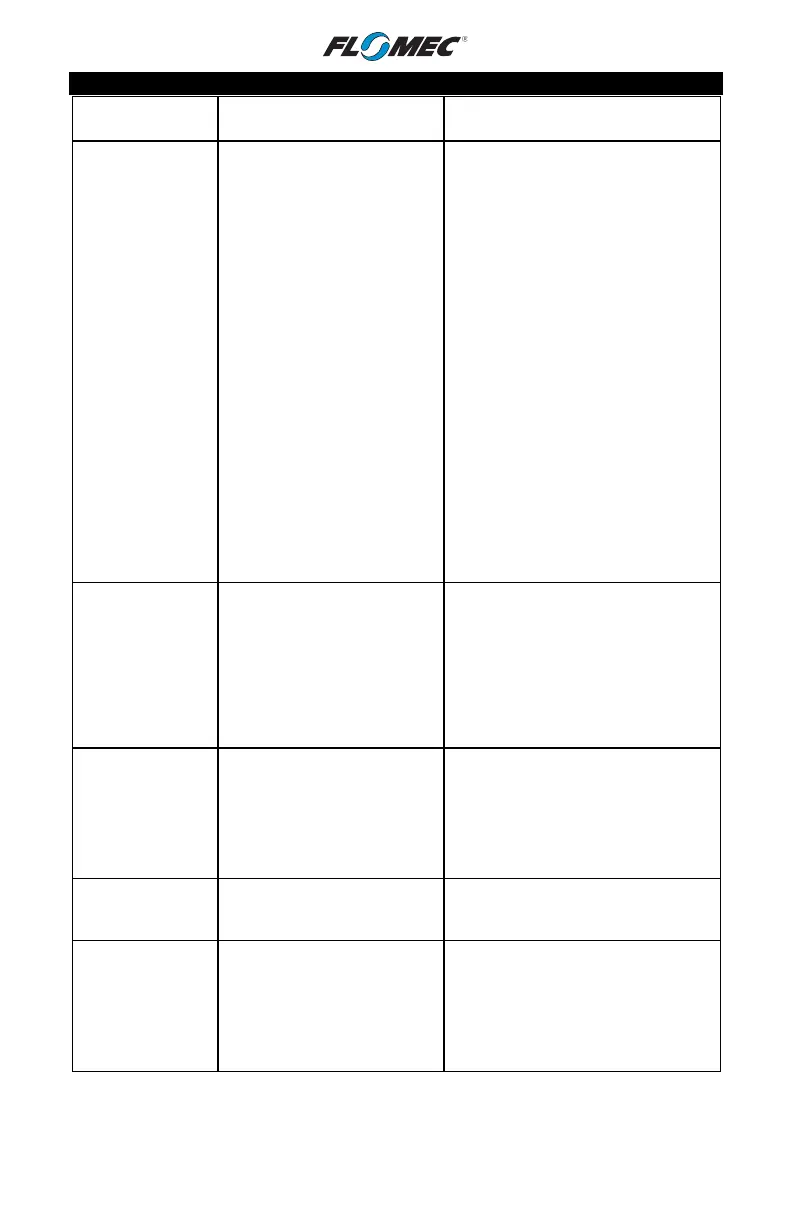

TROUBLESHOOTING

Symptom Probable Cause Corrective Action

A. INACCURATE

TOTALS /

FLOWRATE.

1. Field Calibration not

performed properly.

2. Factory Calibration not

suitable for liquid being

measured.

3. Meter operated below

minimum flowrate.

4. Meter partially clogged with

dried liquid.

5. Turbine bearings partially

clogged with dried liquid.

6. Sealant material wrapped

around meter rotor.

7. Meter installed too close to

fittings.

8. Meter installed to close to

motors or electrically “noisy”

environment.

Field calibrate again or select Factory

Calibration.

Perform a Field Calibration according

to Field Calibration Section.

Increase flowrate.

Remove meter. Clean carefully. Make

sure rotor spins freely.

Remove meter. Clean carefully. Make

sure rotor spins freely.

If applicable, remove rotor. Make sure

rotor spins freely.

Install correctly.

Install correctly.

B. BUTTON NOT

WORKING.

1. Button plunger not fully

pressed.

2. Button only operates upon

release.

3. Assembly issue.

4. Configuration issue.

Ensure finger covers entire button.

Release button to see display change.

Contact the factory.

Contact the factory.

C. “BA0.000” IS

DISPLAYED.

1. Configuration issue. a. Reset Batch and Accumulative

Totals.

b. Performing a Field Calibration may

allow desired performance.

c. Contact the factory.

D. WEIRD

CHARACTERS

ON SCREEN.

1. Assembly issue.

2. Bad LCD.

Contact the factory.

Contact the factory.

E. DISPLAY IS

FADED OR

BLANK.

1. Batteries weak, dead, or

not connected.

2. Ambient temperature is too

cold.

3. Computer defective.

Remove display. Check and replace

batteries.

Place bare hand or warmer on display

for temporary readability.

Contact the factory.

Loading...

Loading...