67

BLITZ

G BG B

G BG B

G B

10-04B

10-04A

1

2

1

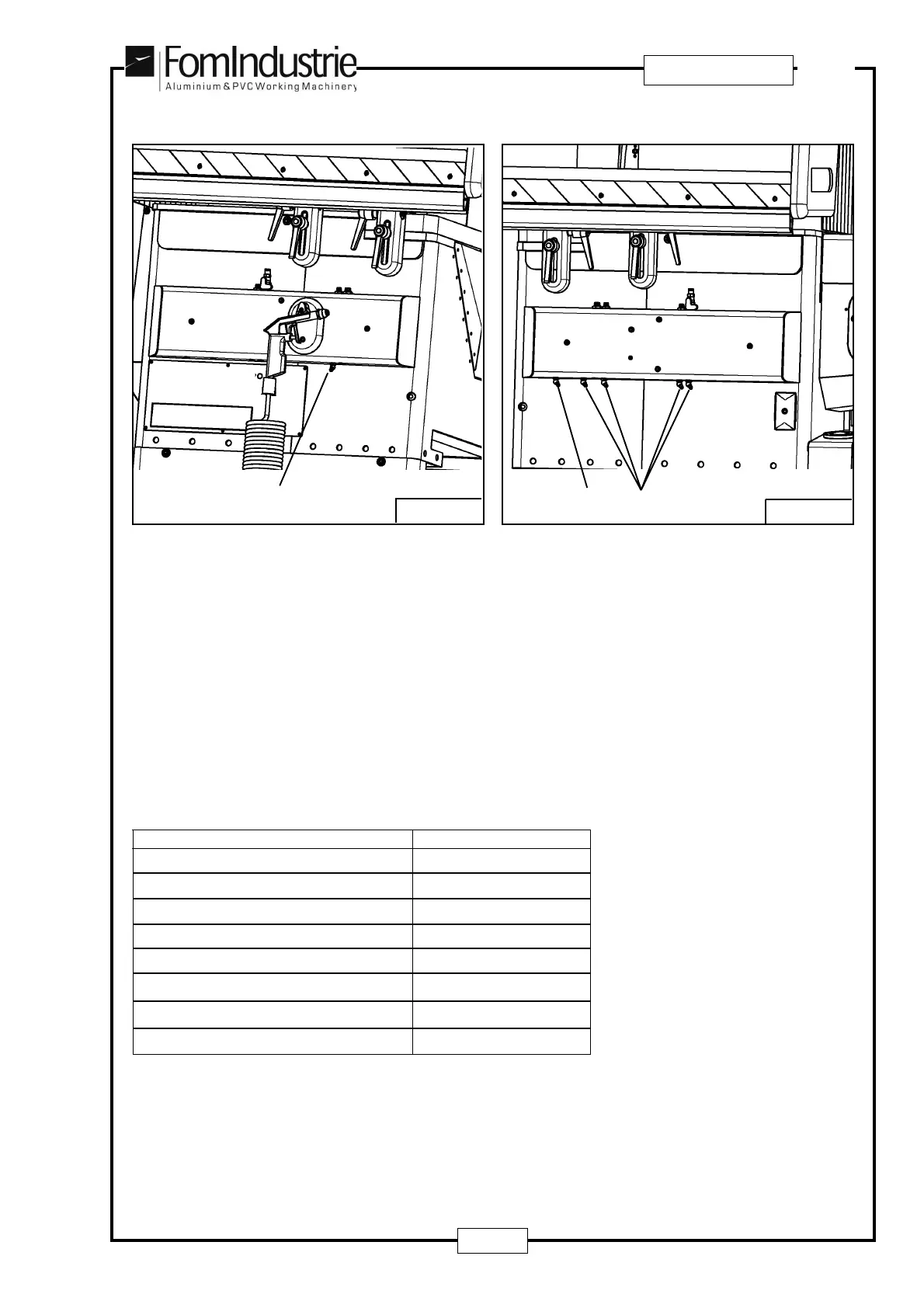

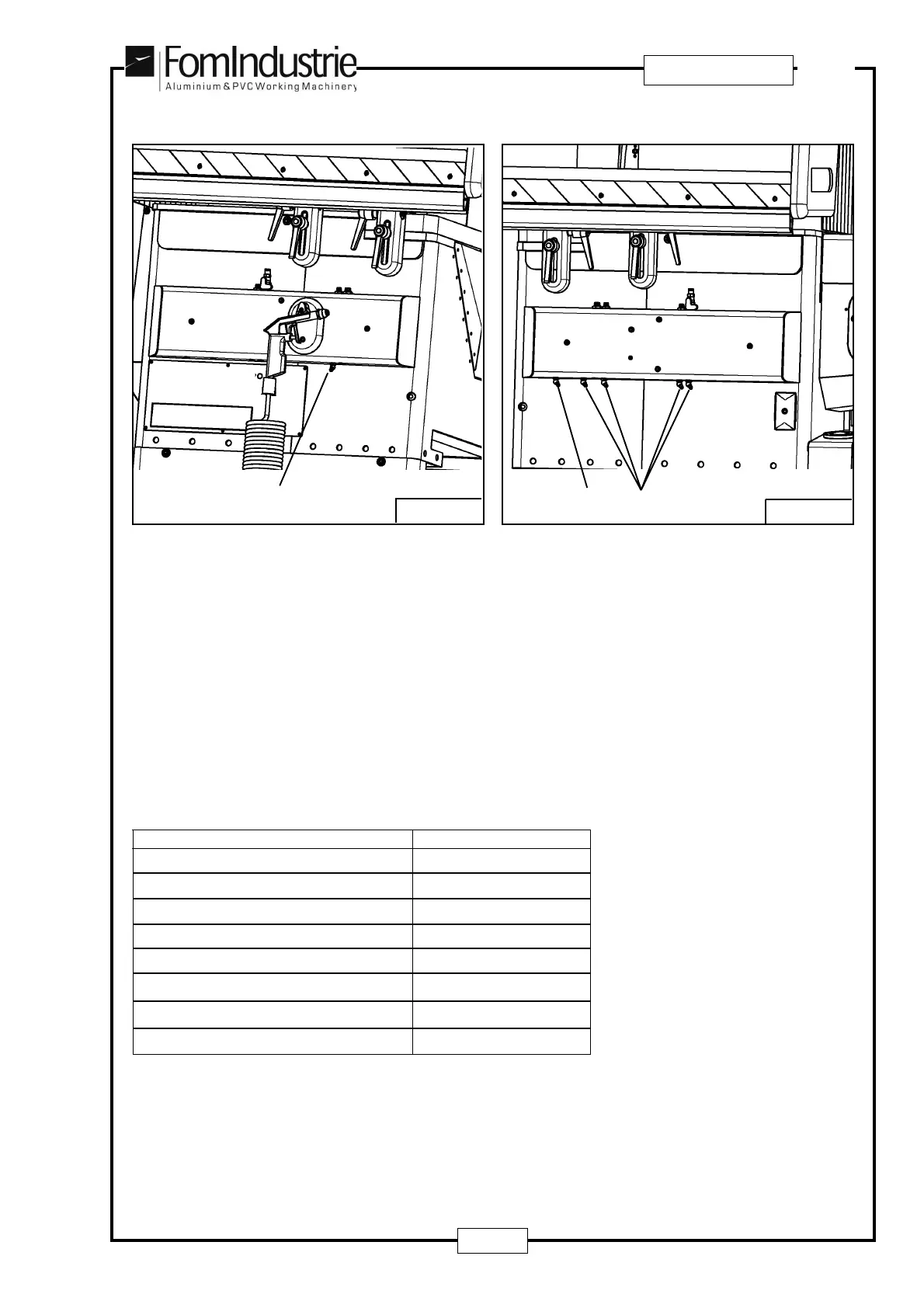

Approx every 900 work cycles each retractable profile support must be greased (if present) by the following

procedure:

1) move the mobile head away from the fixed head and take it to the end of the bench so that the profile supports

can be raised;

2) remove the support cover using screw “3” - Fig. 10-04C

3) apply grease inside race “4” - Fig. 10-04D;

4) put the cover back on the profile support using screw “3” - Fig. 10-04C making sure that the support is set

perpendicularly to the bench.

For each lubrication, pump just once with average force during the operation.

The specifications of the grease to use are given in Table 10-02.

GREASE SPECIFICATIONS

Table 10-02

FOM spare part code for grease: ET-77460 in 1 Kg. packs.

Type of soap Semi-synthetic

Active component Liquilon PTFE

NLGI consistency 0

Working temperature -20 +178 °C

Flash point 276 °C

Density at 40°C 0.904 g/cm

3

Consistency ASTM D217 25°C 285

Evaporation ASTM D972 99°C None

Rust protection ASTM D 1743 Passed

Loading...

Loading...