66

G BG B

G BG B

G B

BLITZ

10.2 PERIODIC MAINTENANCE

- Carefully oil all the exposed mechanical parts (ex. guideways, work table, etc.)

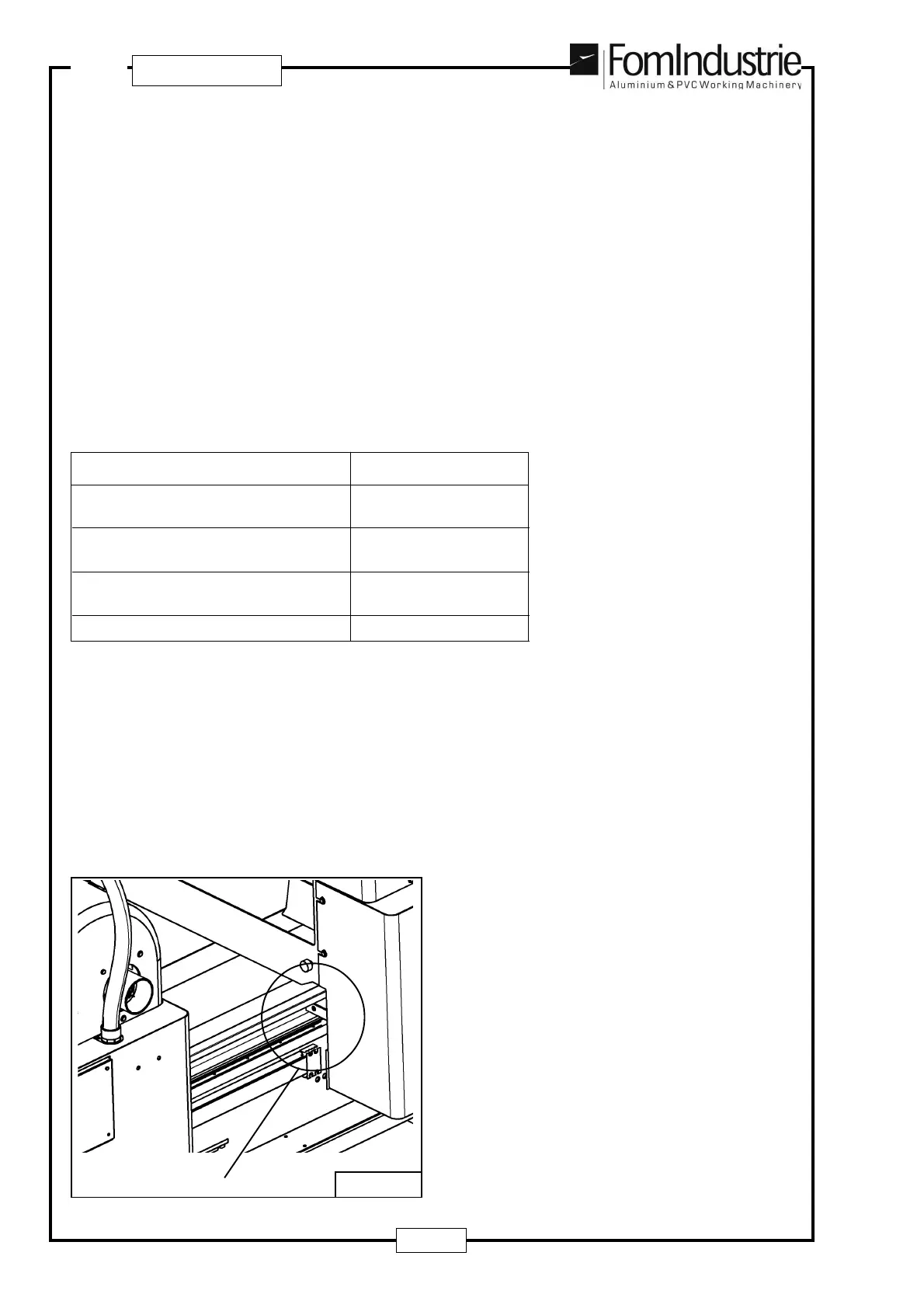

- Clean the chips from under the guideway covers “A” - Fig. 10-03 with a suction hose to prevent the chips

from building up around the fixed head when the mobile head moves in, with consequent difficulties also

during the machine calibration phase.

- Approx. every 200 working hours it is necessary to grease, through the nozzles “1” - Fig. 10-04A / Fig.

10-04B (2), and using the syringe supplied, the recirculating ball screws used to tilt the head.

Approx. every 200 working hours it is necessary to grease, through nozzles “2” - Fig. 10-04B (4) also

the recirculating ball screws with the syringe supplied.

For each lubrication, pump just once with average force during the operation.

The specifications of the grease to use are given in Table 10-01.

GREASE SPECIFICATIONS

Type of soap Lithium - calcium

Work penetration 60 double strikes

(ASTM D 217) 400 – 430 mm/10

Drop point

(ASTM D 566) 165° C

Corrosive to copper

(IP 112 b 5) Negative

Emcor test Passed

FOM spare part code for grease: ET-77906 in 1 Kg. packs.

10-03

Table 10-01

A

Loading...

Loading...