72

G BG B

G BG B

G B

BLITZ

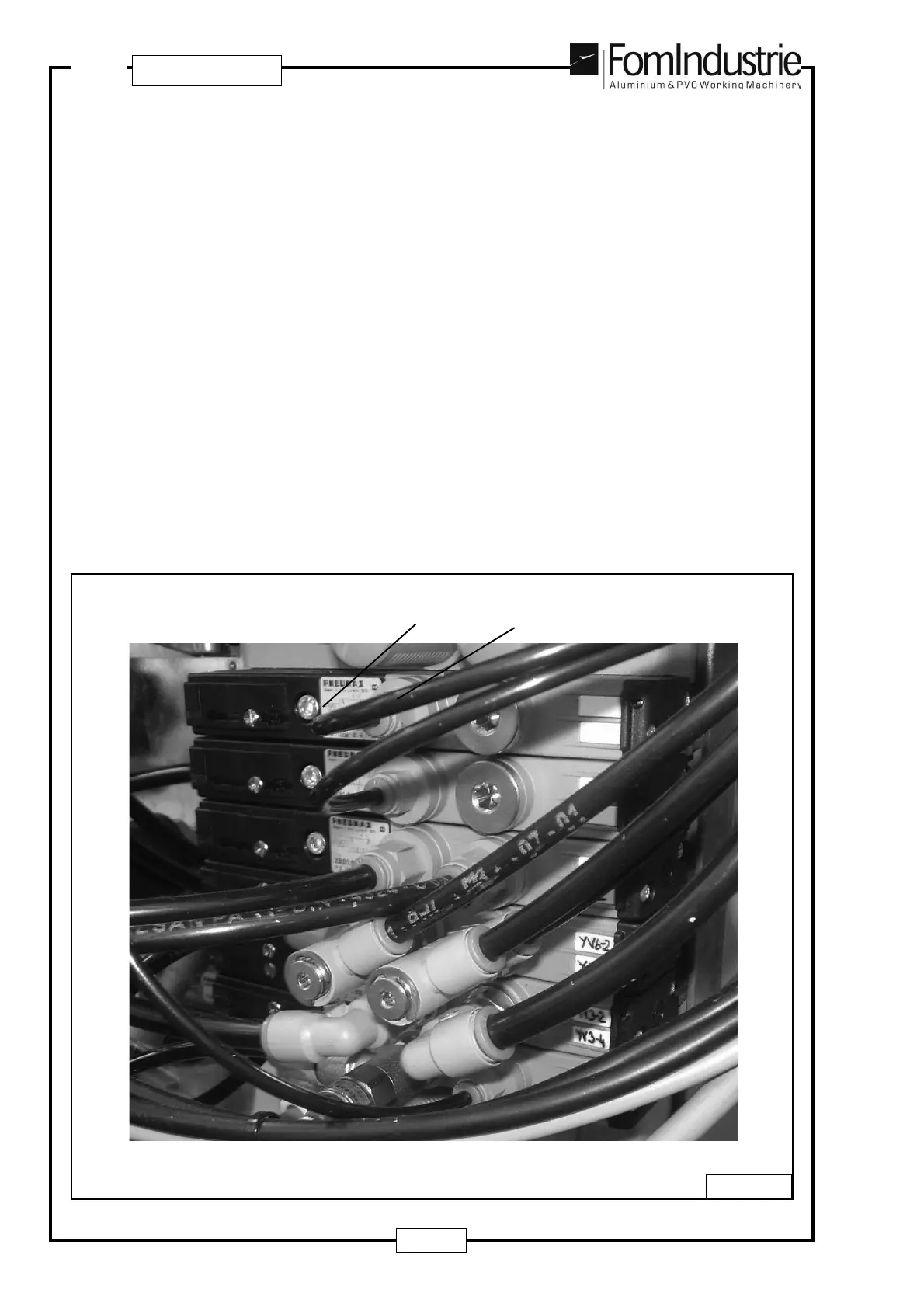

10.5 FITTING NEW SOLENOID VALVES (FIG. 10-10)

The need to fit a new solenoid valve may arise each time one of the electro-pneumatically governed operations

cannot be performed; for example, closing the vices, blade exit, etc.

In this case substitute the relevant solenoid valve by the following procedure:

1) Turn the pneumatic master switch to “0” and secure it with a padlock. Then open the main switch and

secure that too with a padlock.

2) Open the rear safety guard “A” - Fig. 10-09 of the FH or MH (depending on which solenoid valve needs

replacing) using the 4 fixing screws.

3) Disconnect the air tubes.

4) Undo screw “C” and then pull out the solenoid valve by turning it through 90°.

5) Fit the new solenoid valve to the sub-base (turning it through 90°) and fix it in place with screw “C” (there

is only one way round to fit it).

6) Disconnect the air tubes “B”.

7) Refit and secure the rear safety guard.

8) Release the pneumatic master switch and set it to “I”, remove the padlock from the main switch, then

restore power to the machine using the same switch.

9) Carry out a few test runs.

10-10

B

C

Loading...

Loading...