Drive Axles with Differential

Lock

Drive Axles with Main Differential

Lock

The main differential lock is a driver-controlled trac-

tion device operated from the vehicle cab. A dash

switch controls the side to side lock-up of the rear

axle, supplying equal traction to both sides. On tan-

dem axles there are three possible differential lock

options:

•

Forward-rear carrier only

•

Rear-rear carrier only

•

Both rear carriers.

An indicator light comes on when the differential lock

is engaged. An optional buzzer can also be used to

indicate differential lock engagement.

The main differential lock provides maximum traction

under slippery conditions. When the differential lock

is engaged, the clutch collar completely locks the

differential case, gearing, and axle shafts together,

maximizing traction of both wheels and protecting

against spinout. Under normal traction conditions, do

not engage the differential lock. Operate the axle

with differential action between both wheels.

WARNING

Be especially careful when driving under slippery

conditions with the differential locked. Though

forward traction is improved, the vehicle can still

slip sideways, causing possible loss of vehicle

control, personal injury, and property damage.

Main Differential Lock Operation

To lock the main differential and obtain maximum

traction under slippery conditions, move the control

switch to the lock position.

NOTE: On some vehicles, the differential lock

system is connected through the low speed

range of the transmission. If this system is used,

the transmission must be in the low speed

range for the differential to fully lock.

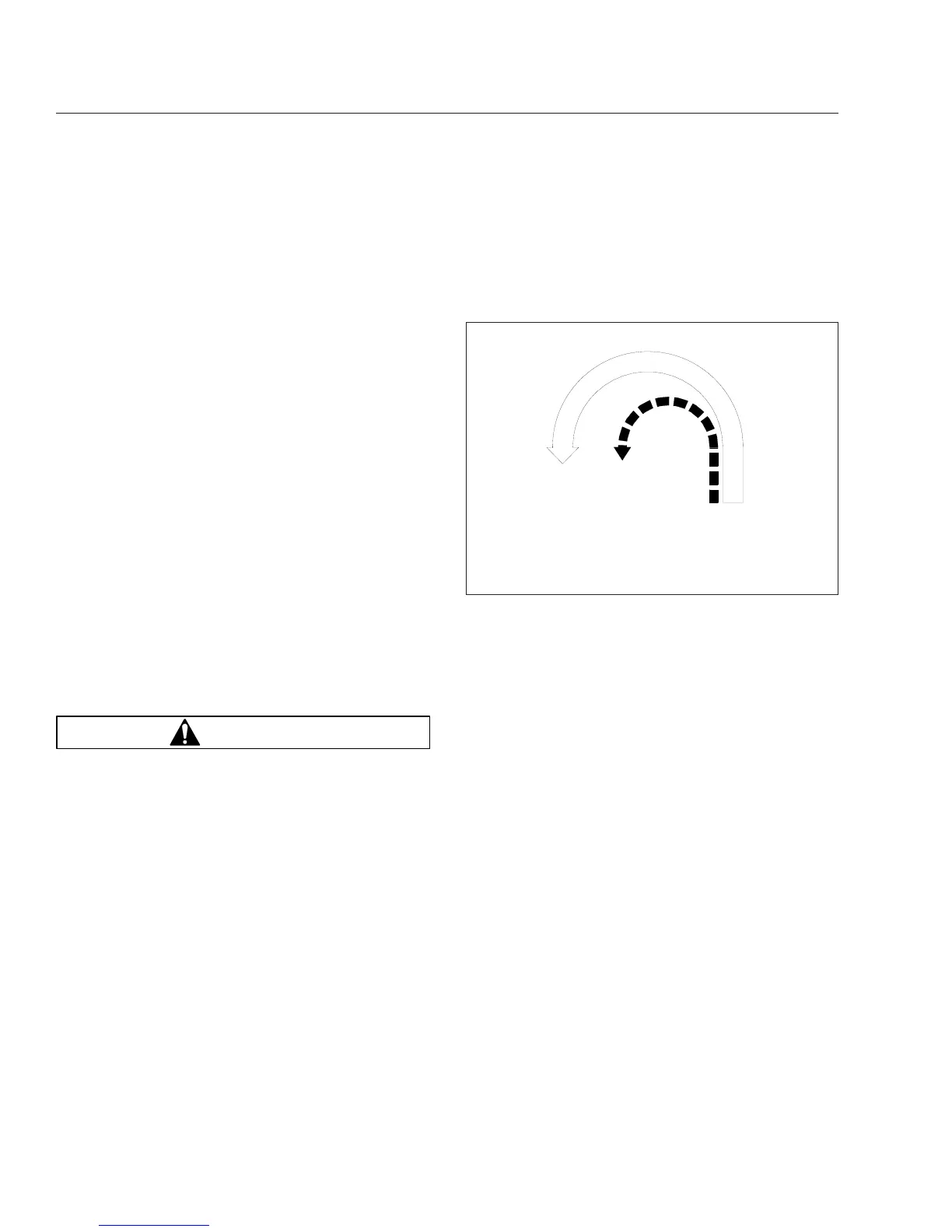

If the vehicle is moving, maintain a constant vehicle

speed while engaging the differential lock. Briefly let

up on the accelerator to relieve torque on the gear-

ing, allowing the differential to fully lock. The indica-

tor light should come on and the buzzer should

sound on vehicles so equipped. When the differential

is fully locked, the turning radius will increase be-

cause the vehicle understeers. See

Fig. 15.1. Drive

cautiously and do not exceed 25 mph (40 km/h).

To unlock the main differential, move the control

switch to the unlock position. Briefly let up on the

accelerator to relieve torque on the gearing, allowing

the differential to fully unlock.

NOTE: If the differential lock system is con-

nected through the low speed range of the

transmission, shifting out of low speed range will

also unlock the differential.

When the differential lock disengages, the indicator

light will go off and the buzzer will stop.

Tandem Drive Axles with Interaxle

Differential

Tandem drive axles with an interaxle differential have

a lockout feature. Differential lockout is controlled by

a switch (

Fig. 15.2) on the control panel.

In the UNLOCK position, there is differential action

between the two axles. The differential compensates

for different wheel speeds and variations in tire size.

Keep the interaxle differential unlocked for normal

driving on roads where traction is good.

In the LOCK position, the interaxle differential is

locked out and the driveshaft becomes a solid con-

nection between the two axles. Power entering the

02/09/96

f350079a

A

B

A. Turning Radius When Differential is Locked

(engaged)—Understeer Condition

B. Turning Radius When Differential is Unlocked

(disengaged)

Fig. 15.1, Turning Radius

Drive Axles

15.1

Loading...

Loading...