4.

Position the tractor so that the center of the fifth

wheel is in line with the trailer kingpin. The king-

pin should be in a position to enter the throat of

the locking mechanism.

NOTICE

Attempting to couple at the wrong height may

cause improper coupling, which could result in

damage to the fifth wheel or kingpin.

5.

Adjust the trailer height if required.

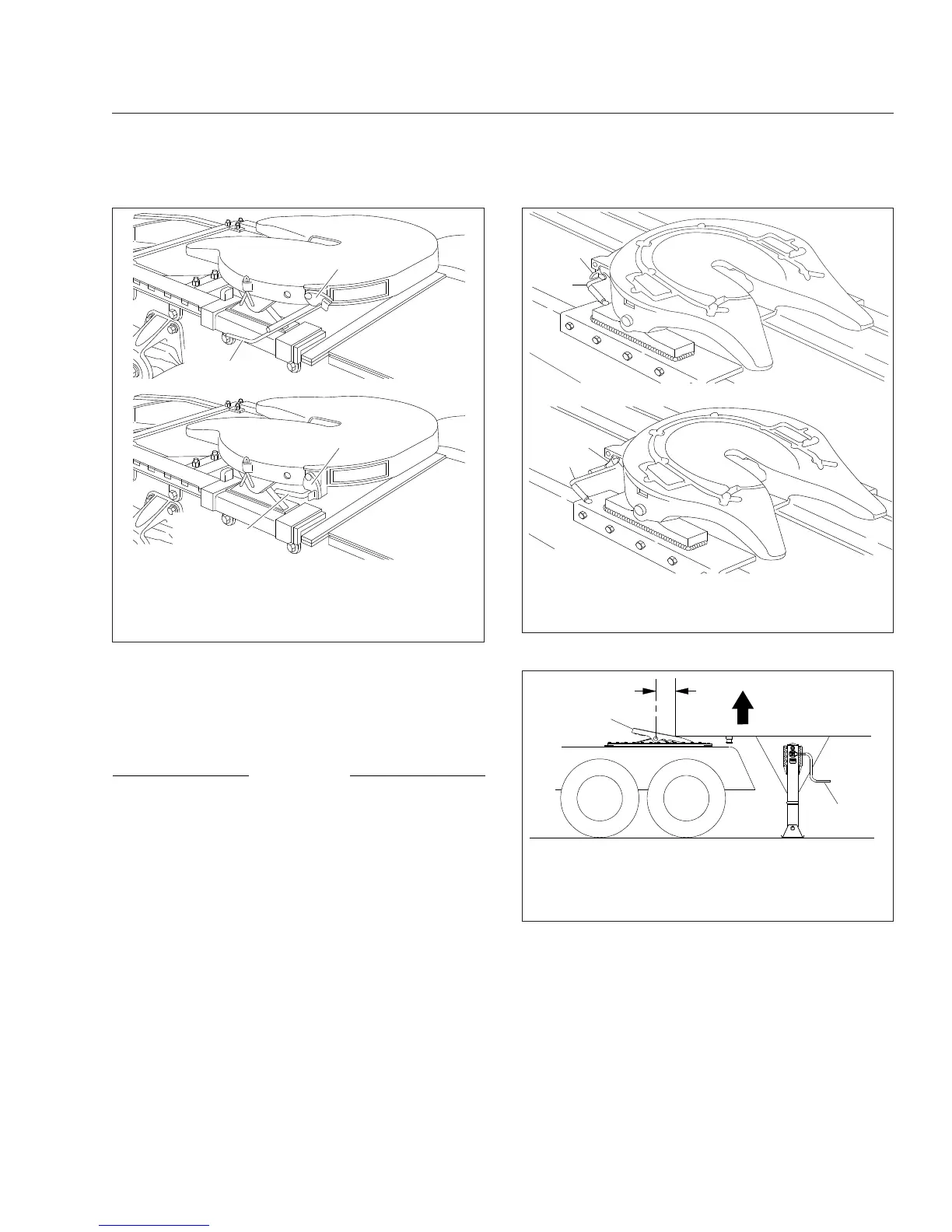

For a standard fifth wheel plate, the trailer

should contact the fifth wheel approximately 4 to

8 inches (10 to 20 cm) behind the fifth wheel

pivot. See

Fig. 17.4.

For a low-lube fifth wheel plate, the fifth wheel

must slide freely under the trailer, and the trailer

should contact the fifth wheel at the pivot. See

Fig. 17.5.

6.

With the fifth wheel lock opening aligned with the

trailer kingpin, back the tractor slowly toward the

trailer. After sliding under the trailer, STOP to

prevent from hitting the kingpin too hard, then

resume backing slowly until the fifth wheel locks.

On a standard fifth wheel, the fifth wheel must lift

the trailer.

On a low-lube fifth wheel, do not lift the trailer as

this may damage the fifth wheel plate.

1

1

2

2

10/26/2010

f310110a

A

B

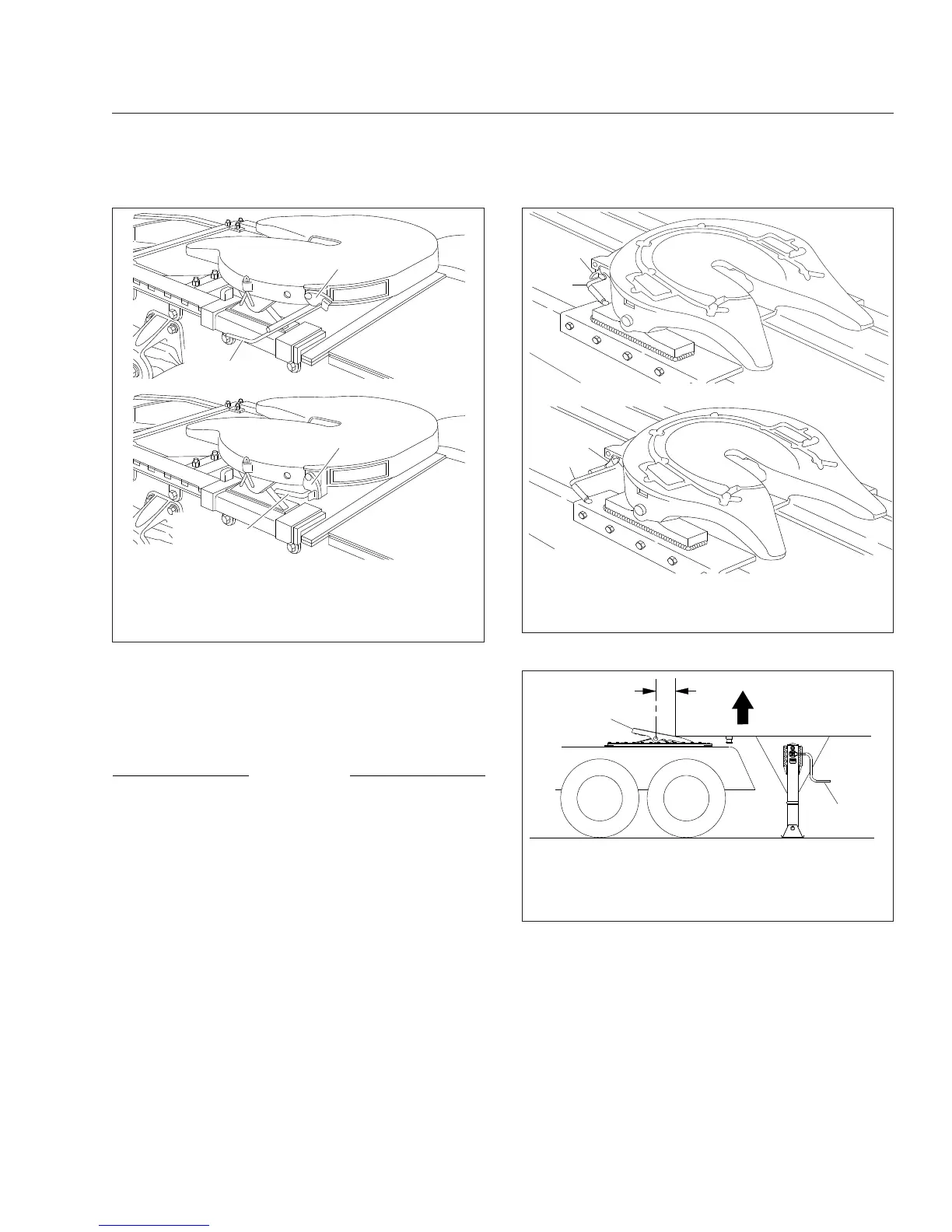

NOTE: Make sure the safety latch is down when the

control handle is locked.

A. Unlocked B. Locked

1. Safety Latch 2. Lock Control Handle

Fig. 17.2, Fontaine Locking Mechanism

1

1

2

3

11/02/2010

f310447

1. Safety Latch

2. Operating Rod (locked)

3. Operating Rod (unlocked)

Fig. 17.3, Holland Simplex SE Locking Mechanism

10/28/2010 f311124

A

B

C

D

A. Fifth wheel must lift

trailer

B. Adjust trailer height

C. Ramps tilted down

D. 4 to 8 inches

Fig. 17.4, Trailer Connection Point, Standard Fifth

Wheel

Fifth Wheels

17.2

Loading...

Loading...