1.

If the vehicle was originally equipped with wheel

covers, ensure all wheel covers are present. In-

spect wheel covers for damage or wear. Remove

wheel covers from rear drive wheels, if equipped,

prior to inspecting the tires and wheel compo-

nents.

NOTE: During wheel cover installation, ensure

the V-notch in the liner inner retaining ring is

centered on the valve stem. The inner and outer

retaining rings should be uniformly aligned to

each other and to the wheel rim. The outer re-

taining ring of the liner is equipped with two

canvas flaps. When installing the face cover,

make sure the cover retaining ring is inserted

between the two canvas flaps on the liner outer

retaining ring so that the Velcro strips line up

between the face cover and the liner. Make cer-

tain the detachable view cover is centered on

the face cover, and the Velcro strips are

pressed firmly in place.

2.

Inspect each tire for the following:

•

valve stem caps on every tire, screwed on

finger-tight

•

bulges, cracks, cuts, and penetrations

•

oil contamination (petroleum derivatives will

soften the rubber and destroy the tire)

•

tread depth—if tread is less than 4/32 inch

(3 mm) on any front tire, or less than 2/32

inch (1.5 mm) on any rear tire, replace the

tire

•

debris lodged between duel tire sets

IMPORTANT: Low-rolling resistance (LRR) tires

minimize wasted energy as a tire rolls, thereby

decreasing rolling effort and improving fuel effi-

ciency. If tire replacement is necessary, replace-

ment tires must meet or exceed the rolling resis-

tance of the originally installed tires in order to

maintain compliance with greenhouse gas and

full efficiency regulations (GHG14).

Contact your tire manufacturer/supplier to deter-

mine the rolling resistance of the originally in-

stalled tires. Visit

www.epa.gov/smartway for

additional information and resources.

3.

Check tire inflation.

For inflation pressures and maximum loads, see

the tire manufacturer’s guidelines. Inflate the tires

to the applicable pressures if needed.

If a tire has been run flat or under-inflated, check

the wheel and tire for damage before adding air.

Keep compressed air reservoirs and lines dry

during tire inflation. Use well-maintained inline

moisture traps and service them regularly.

WARNING

Do not operate the vehicle with underinflated or

overinflated tires. Incorrect inflation can stress

the tires and make the tires and rims more sus-

ceptible to damage, possibly leading to rim or

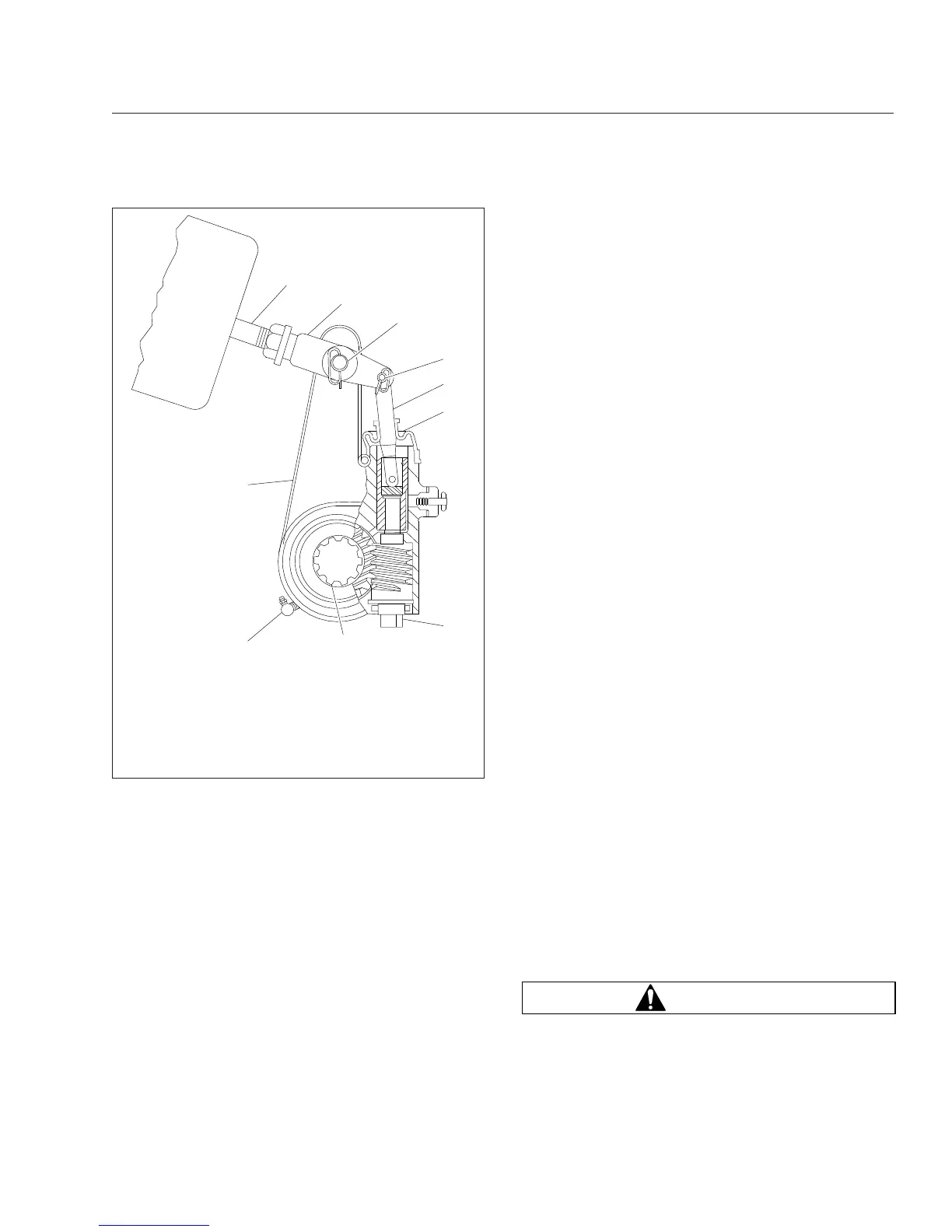

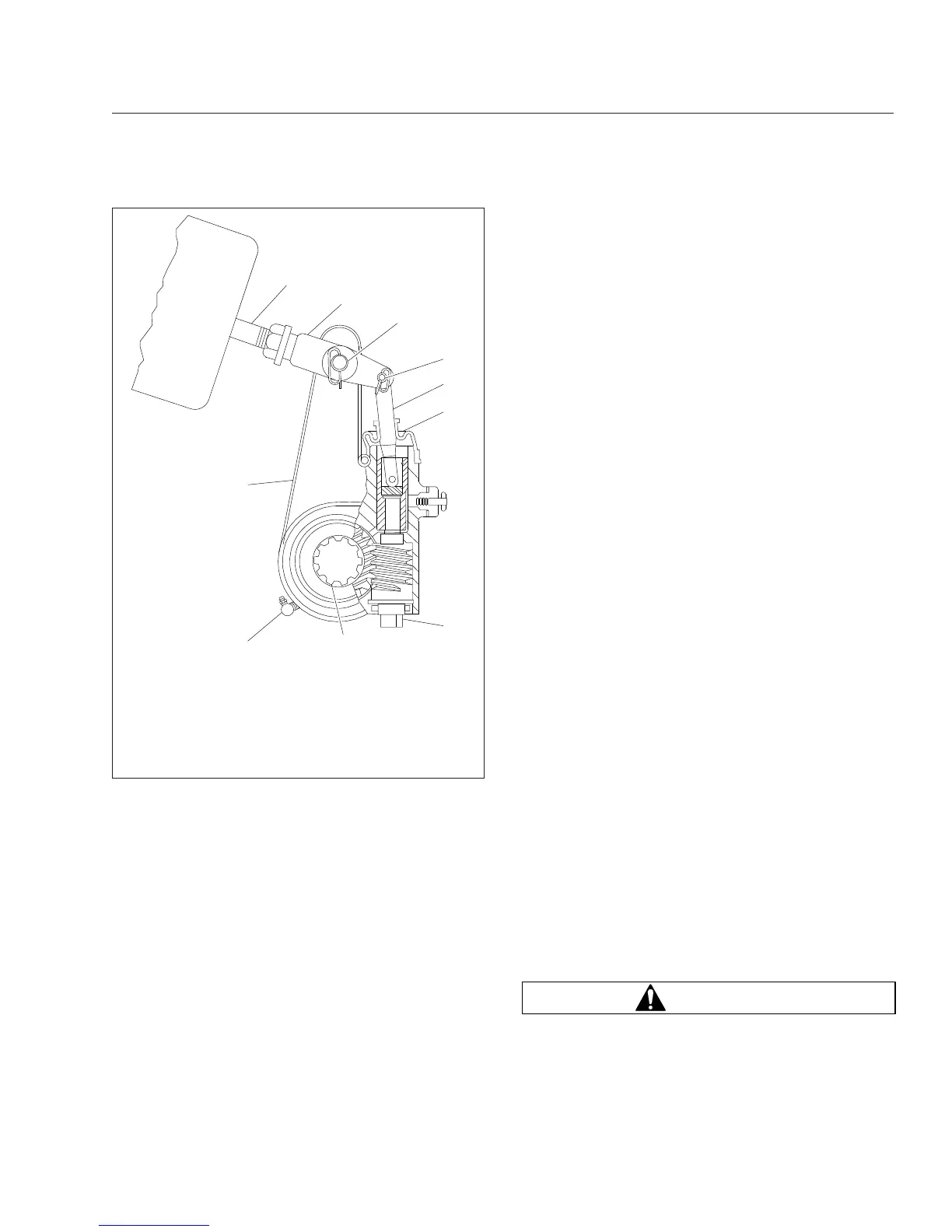

01/31/2011 f422530

1

2

3

4

5

6

7

8

9

10

1. Grease Fitting (if

equipped)

2. Slack Adjuster

Housing

3. Brake Chamber

Pushrod

4. Clevis

5. Clevis Pin (large)

6. Clevis Pin (small)

7. Actuator Rod

8. Boot

9. Manual Adjusting Nut

10. Camshaft Splines

Fig. 20.2, Meritor Automatic Slack Adjuster

Pre- and Post-Trip Inspections and Maintenance

20.2

Loading...

Loading...