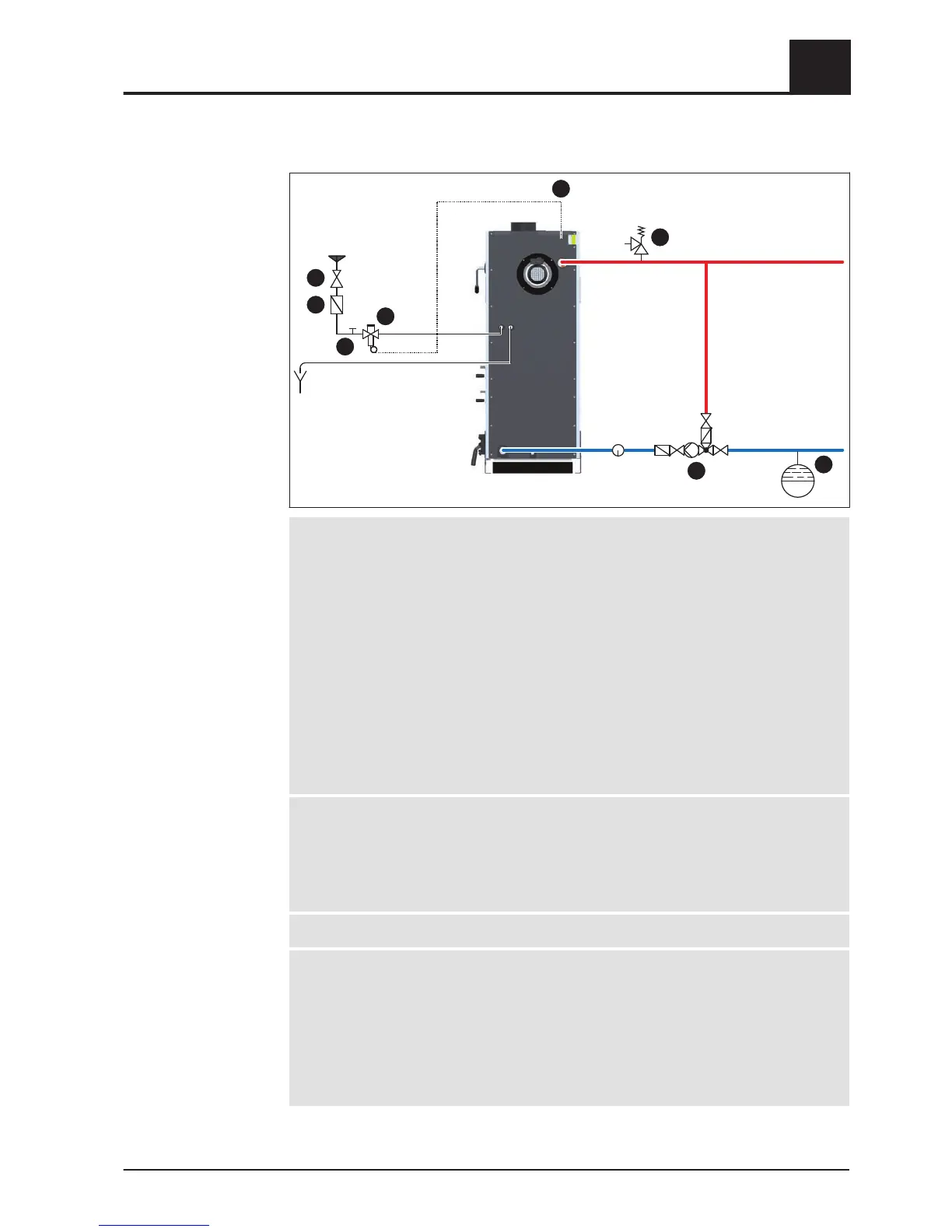

1 Thermal discharge valve

▪

The thermal discharge safety device must be connected in accordance with

ÖNORM/DIN EN 303-5 and as shown in the diagram above

▪ The discharge safety sensor must be connected to a pressurised cold water

mains supply (temperature ≤ 15°C) in such a way that it cannot be shut off

▪ A pressure reducing valve (1.5) is required for a cold water pressure of ≥ 6 bar

Minimum cold water pressure = 2 bar

1.1 Sensor of thermal discharge safety device

1.2 Thermal discharge valve (opens at approx. 95°C)

1.3 Cleaning valve (T-piece)

1.4 Dirt trap

1.5 Pressure reducing valve

1.6 Free outlet without counter pressure

2 Safety valve

▪ Safety valve as per ÖNORM EN ISO 4126-1, diameter as per EN 12828 or

national regulations

▪ The safety valve must be installed in an accessible place on the heat generator or

in direct proximity in the flow pipe in such a way that it cannot be shut off

3 Return temperature control

4 Diaphragm expansion tank

▪

The diaphragm pressurised expansion tank must conform to EN 13831 and hold

at least the maximum expansion volume of the system’s heated water including a

water seal

▪ Its size must comply with the design information in EN 12828 - Appendix D

▪ Ideally it should be installed in the return line. Follow the manufacturer’s

installation instructions

Assembly

4

Connecting the hydraulic safety devices

Installation Instructions S3 Turbo | M1081217_en 57

Loading...

Loading...