S3 Turbo - WOOD FIRED GASIFICATION HYDRONIC FURNACE

A 851 02 19 - T249260

INSTALLATION HAZARDS

Install, modify and use only in accordance with manufacturer’s manuals. Refer to authorities having jurisdiction for

proper installation. Contact local building and fire officials about restrictions and installation inspection in your area. If

there are no applicable local codes, follow ANSI/NFPA 211 and CAN/CSA B365. Special precautions are required

for passing the chimney through a combustible wall or ceiling.

Inspect and clean exhaust system, loading chamber, burning chamber, ash-pits, and heat exchanger frequently in

accordance with owner’s manual.

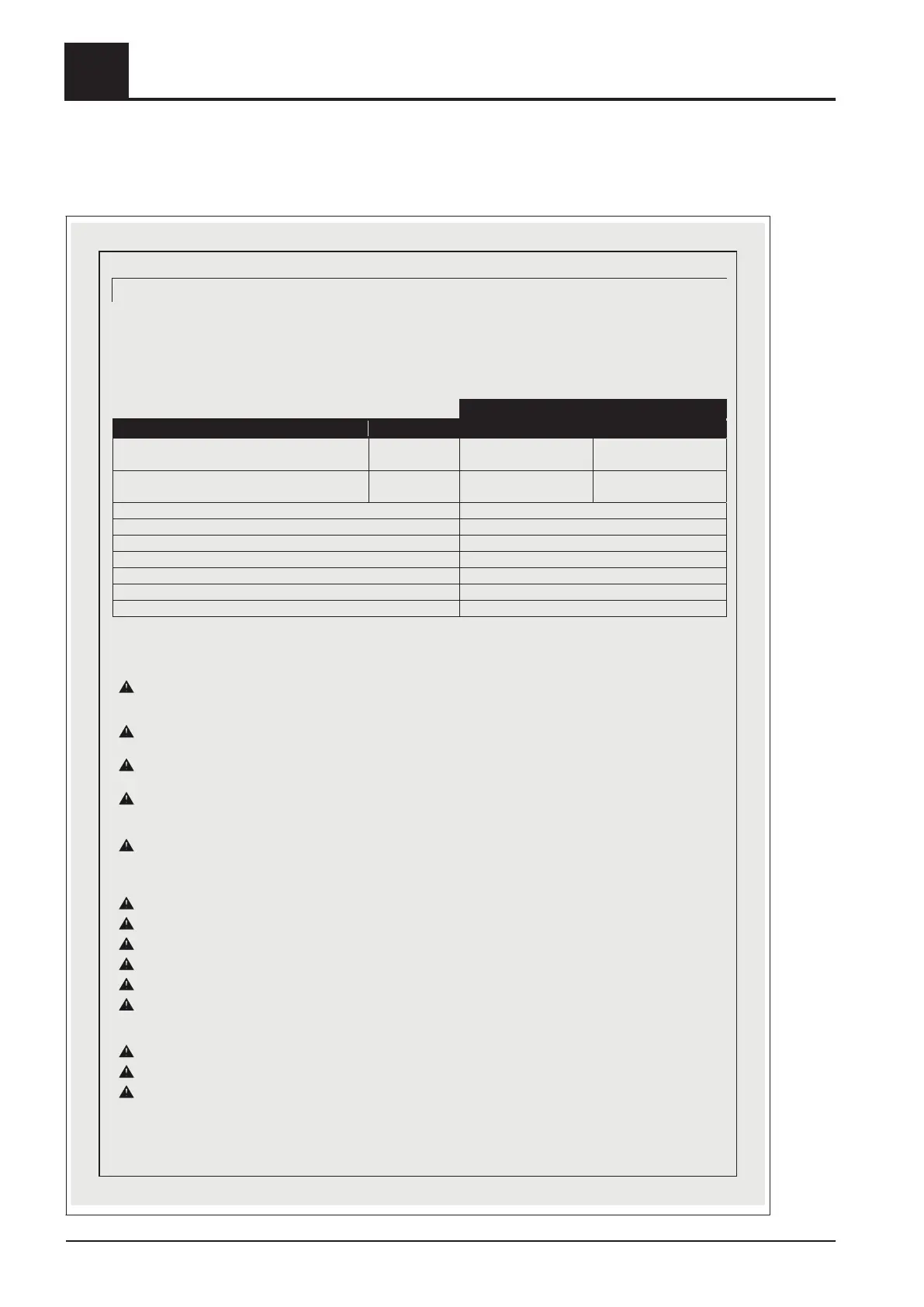

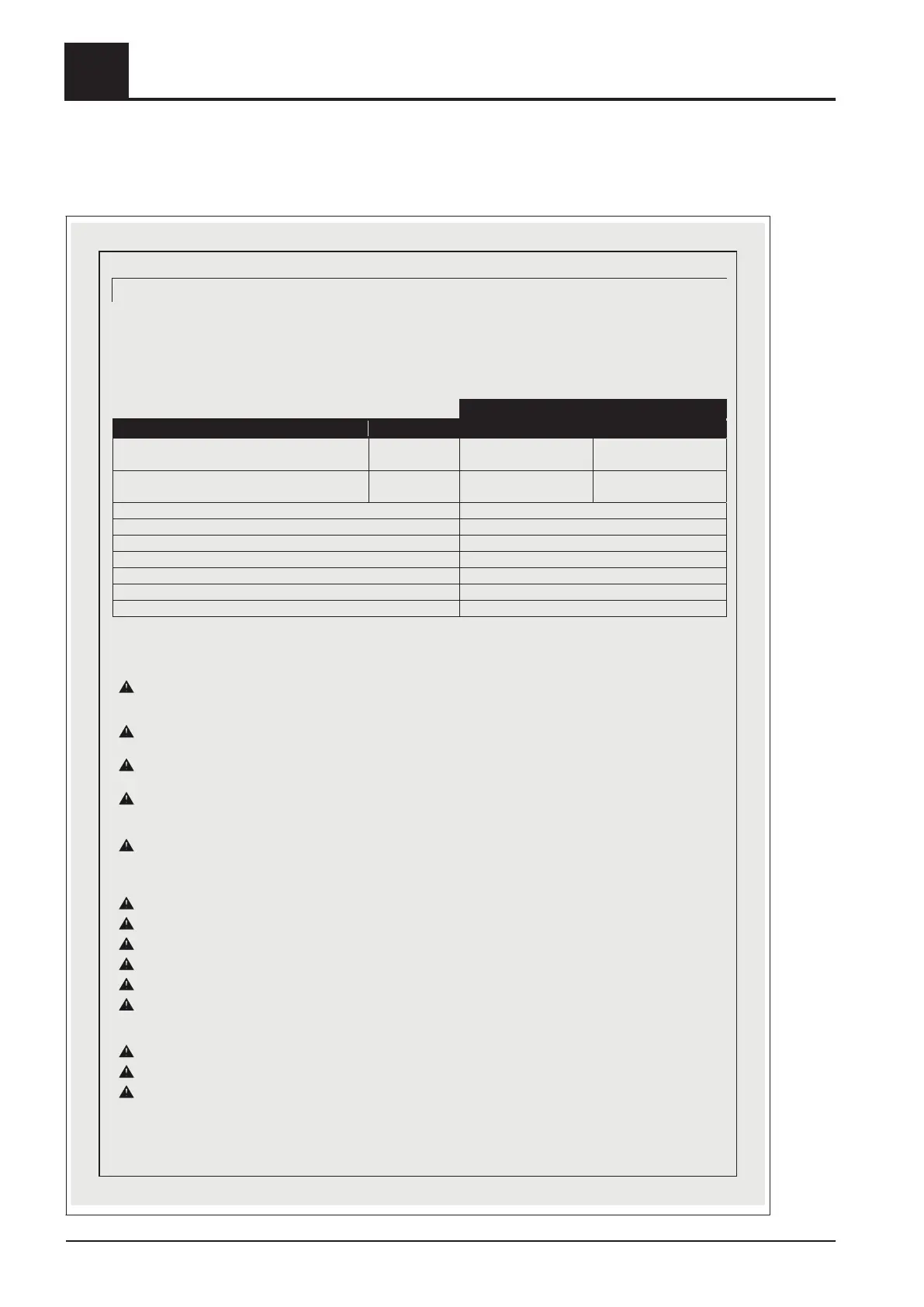

Basic boiler data for layout of chimney system

S3 Turbo

Quantity Unit 30 50

051 / 022 051 / 022 C° erutarepmet sag eulF

003 / 034 003 / 034 F° daol laitrap / detaR

56 / 221 34 / 67 h / gk wolf ssam sag eulF

341 / 072 59 / 761 h / bl daol laitrap / detaR

)nmuloc retaw sehcni 30.0( aP 8 noitcennoc sag eulf sreliob ta tfard muminiM

)nmuloc retaw sehcni 21.0( aP 03 noitcennoc sag eulf sreliob ta tfard mumixaM

)sehcni 6( mm 051 retemaiD rotcennoc sag eulF

)F° 091( C° 88 erutarepmet retaw mumixaM

)isp 03( rab 2 erusserp gnikrow elbawolla mumixaM

)isp 72.76( rab 5.4 erusserP tseT

Mimimum Pressure Relief Valve )h/utB 000,535( Wk 551 yticapaC

For detailed design information please refer to Installation Manual!

For unit specifications, see the plaque located directly on the boiler!

DANGER!

Working on electrical components may cause severe injuries from electric shocks!

WARNING!

The electrical system of the boiler shall be supplied from a double 115 V 60 Hz (nominal 230 V AC) 15 amp

branch circuit including neutral and earth connection. For wiring instructions please refer to installation Manual!

Chimney must be 6’’ (150 mm) diameter listed UL-103 HT or ULC-S629 residential all-fuel type or tile-lined

masonry. Flue connector pipe must be 6’’ (150 mm) diameter made of a minimum 24 MSG black steel.

Inadequate design, installation and maintenance of the flue gas system will lead to insufficient chimney draft and

could result in Danger of Life or Severe Injury caused by serious faults in combustion, e.g. explosivel

combustion of carbonization gases and flash fires!

This boiler requires fresh air for safe operation and must be installed so there are provision for adequate

combustion and ventilation air!

CAUTION!

DO NOT CONNECT THIS UNIT TO A CHIMNEY FLUE SERVING ANOTHER APPLIANCE!

LOAD FUEL CAREFULLY OR DAMAGE WILL RESULT.

REFER TO OWNER´S MANUAL. DO NOT ALTER THIS EQUIPMENT IN ANY WAY.

UNSAFE TO ADJUST FLUE DRAFT HIGHER THAN 0.12 INCHES WATER COLUMN (30 Pa).

MAY BE CONNECTED TO AN EXISTING BOILER SYSTEM.

Flooring must be a minimum 3/8’’ (10 mm) non-combustible material covering the installation clearance area! The

base shall be horizontally, planar and reinforced if required. For construction of base please mind the weight o

Loading...

Loading...