Output signals

from the robot to

the power source

Seq. no. Signal designation Field Activity

A01 Current-flow signal

(with active welding arc)

- High

A02 Limit signal (with RCU 5000i) - -

A03 Process active - High

A04 Main current signal - High

A05 Torch collision protection - High

A06 Power source ready - High

A07 Communication ready - High

A08 Reserve - -

A09 Error number bit 0 (value 1) - High

A10 Error number bit 1 (value 2) - High

A11 Error number bit 2 (value 4) - High

A12 Error number bit 3 (value 8) - High

A13 Error number bit 4 (value16) - High

A14 Error number bit 5 (value 32) - High

A15 Error number bit 6 (value 64) - High

A16 Error number bit 7 (value 128) - High

A17 - A24 Unused - Low

A25 Wire stick control - High

A26 - A32 Unused - -

A33 - A48 Actual value: welding voltage 0 - 65535 0 - 100 V

A49 - A64 Actual value: welding current 0 - 65535 0 - 1000 A

A65- A72 Actual value: motor current 0 - 255 0 - 5 A

Pulse correction

A73 - A80 Unused - -

A81 - A96 Actual value: wire feeder 0 - 65535 0 - 22 m

A97 Output 1 - 0 - 22 m

A98 Output 2 - -

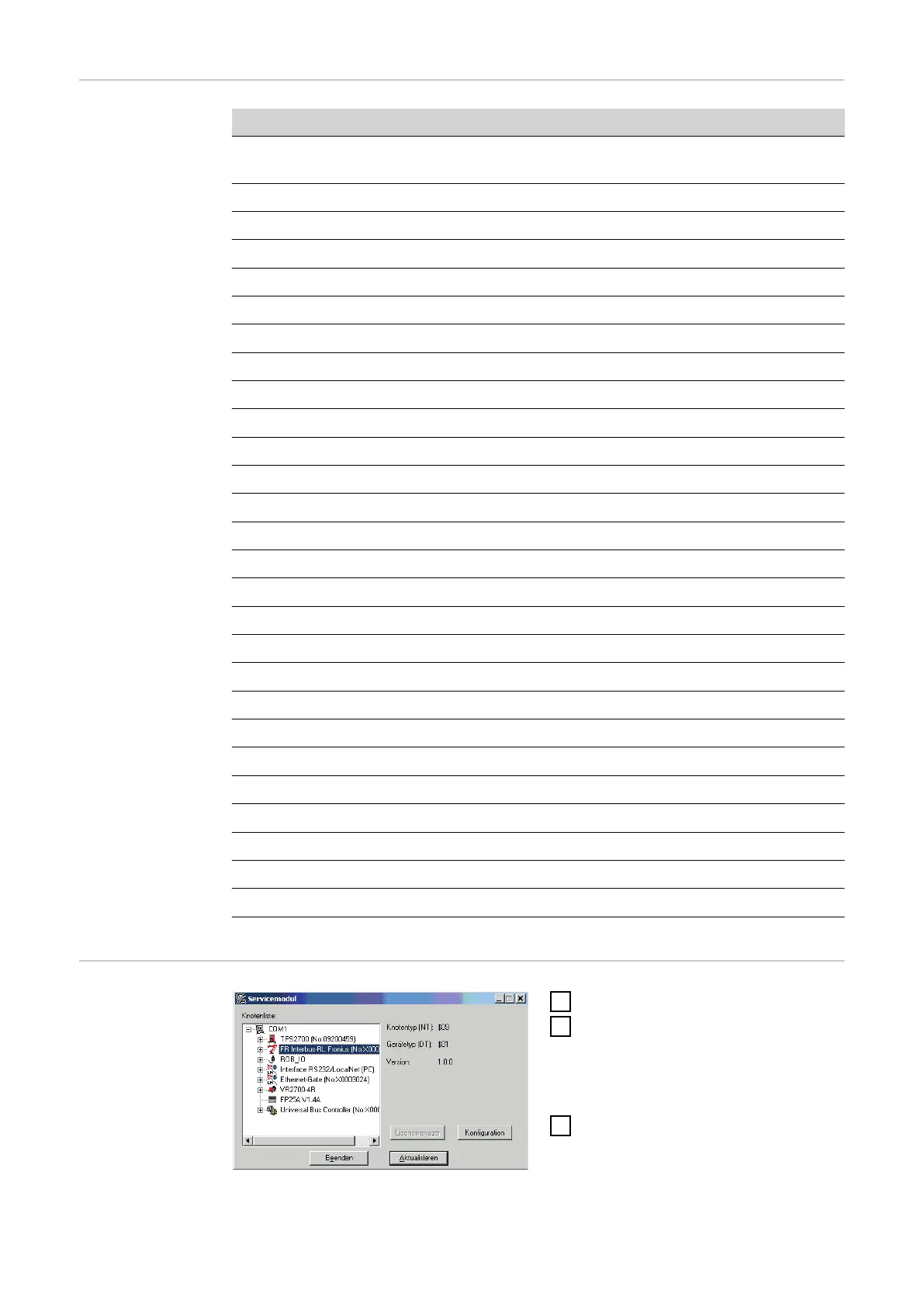

How to configure

ROB I/O

1

Open Service Module software

2

On the Service Module screen

(node list), mark the item „FR In-

terbus-RL Fronius ...“

-

The Configuration button is

activated

3

Click the Configuration button

The Configuration Fieldbus dialog box opens.

18

Loading...

Loading...