6

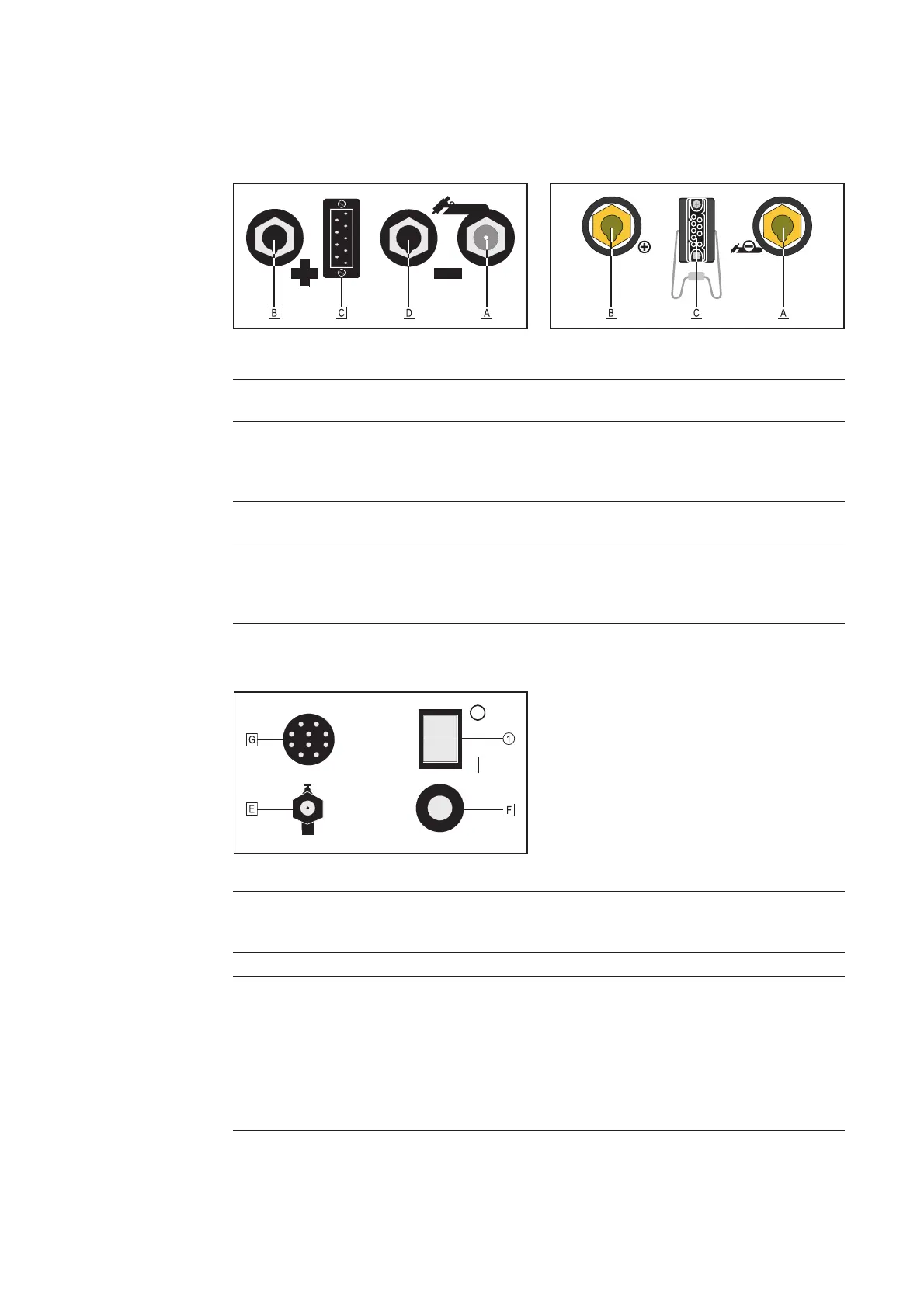

Connection

points on front of

machine

Connections, switches and system add-ons

Fig. 3 Design with central welding torch connec-

tion GWZ

Fig. 4 Design with central welding torch connec-

tion F

[A] TIG TORCH CONNECTION

- for connecting the GAS + CURRENT supply for the welding torch

[B] (+) SOCKET with bayonet coupling

- as the earth cable connection point with TIG welding;

- as the connection either for the manual electrode cable or the earth cable

with manual electrode welding, depending on the type of electrode used.

[C] TORCH CONTROL SOCKET

- Steuerstecker des Schweißbrenners einstecken und verriegeln

[D] (-) SOCKET with bayonet coupling

- only for welding torch central connection GWZ

- as the connection either for the manual electrode cable or the earth cable with

manual electrode welding, depending on the type of electrode used.

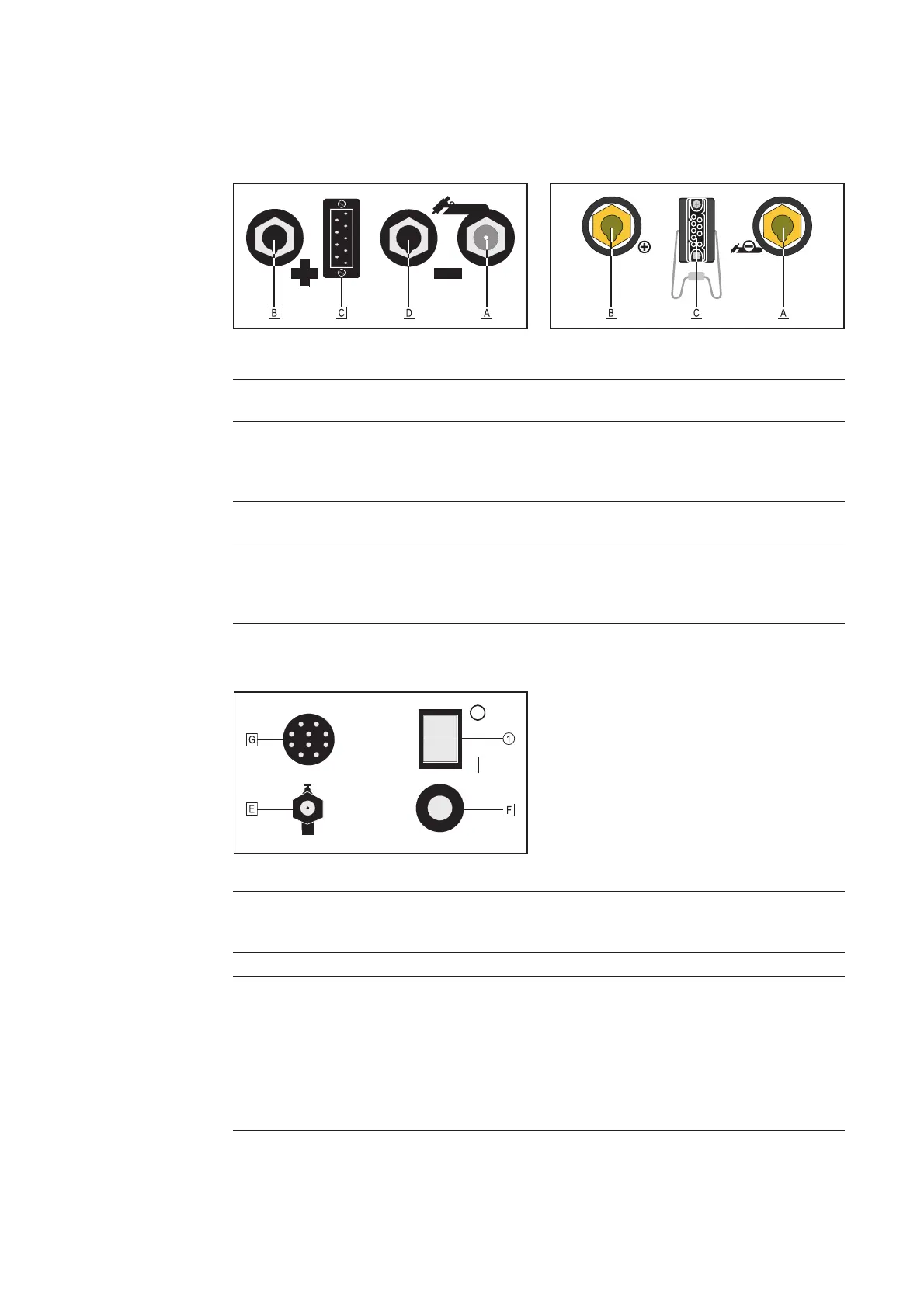

[E] GAS CONNECTION

- Screw the terminal nut of the gas hose onto the connection-fitting and tighten

it

[F] MAINS CABLE WITH STRAIN-RELIEF GRIP

[G] CONNECTING SOCKET for remote control unit

- Plug the remote control cable plug into the socket, the right way round, and

tighten the swivel nut

- The desired welding current is set on the remote control unit.

- The machine automatically recognizes the fact that the remote control unit

has been plugged in

- The short-circuit-proof supply voltage to the remote control units protects the

electronics in the event of any damage to the remote control cable.

Fig. 5 Rear side of the machine

Connections and

switches on the

rear of the machi-

ne

Loading...

Loading...