7

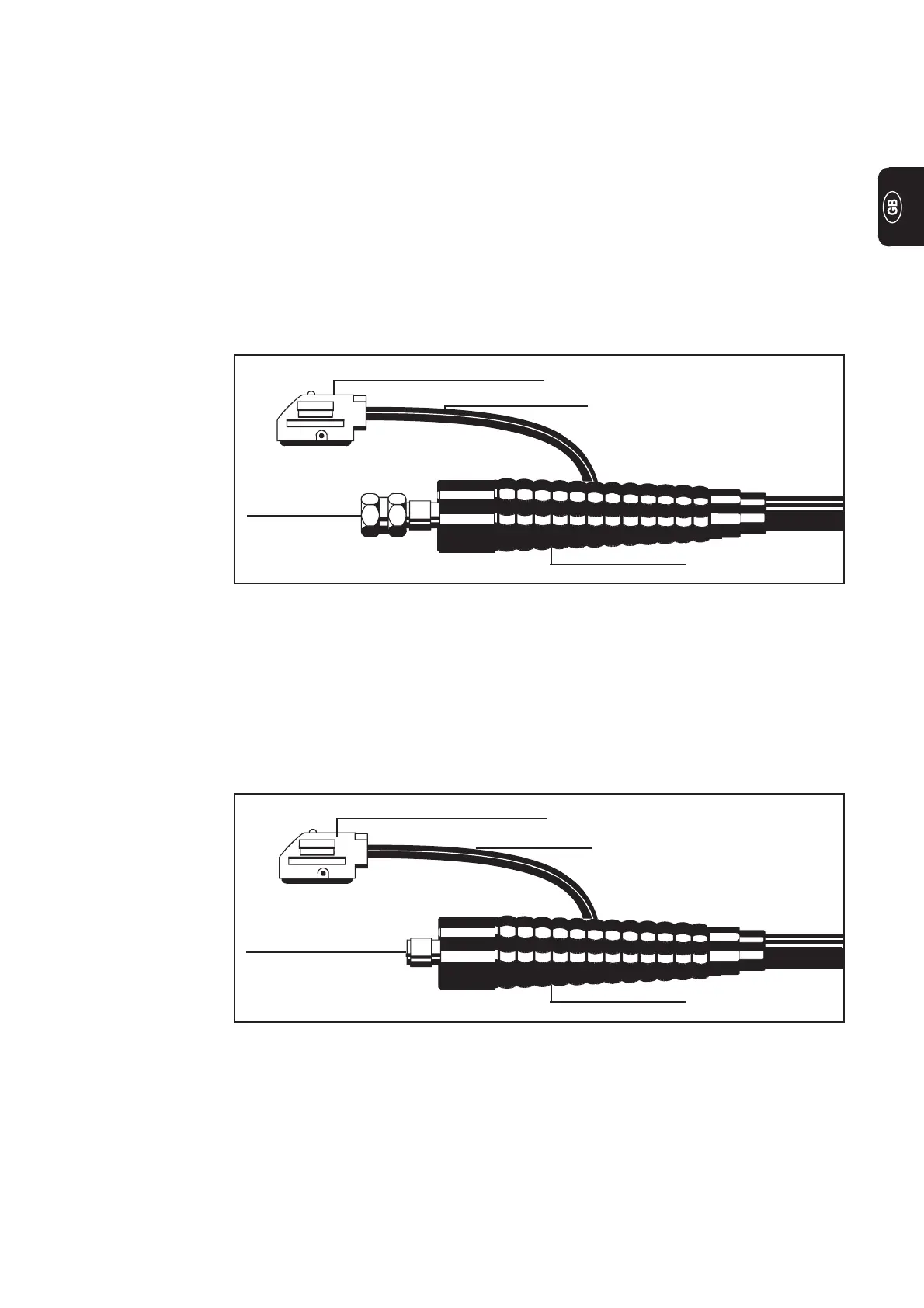

Gas and current

connection

Control plug

Control lead

Fig. 6 Design with central burner connection GWZ: Torch connection gas-cooled

Hose sleeve

- Insert welding torch bayonet connection in the central connection on the equipment

side of the welding torch [A] and lock in place by turning to the right

- Insert control plug in the socket [D] and lock in place

Important! Please see your torch’s instruction manual for technical details on the torch

and for information on torch assembly, care and maintenance.

Assembling a gas-cooled TIG torch

Design with

central burner

connection GWZ

- Pull back the rubber sleeve from the rear of the torch

- Screw the hexagon nut (width across = 21) of the gas+current connection onto the

torch connector point on the machine [A]

and tighten firmly

- Push the rubber sleeve back over the hexagon nut

- Plug the control plug into socket [C] and latch it

Important! Please see your torch’s instruction manual for technical details on the torch

and for information on torch assembly, care and maintenance.

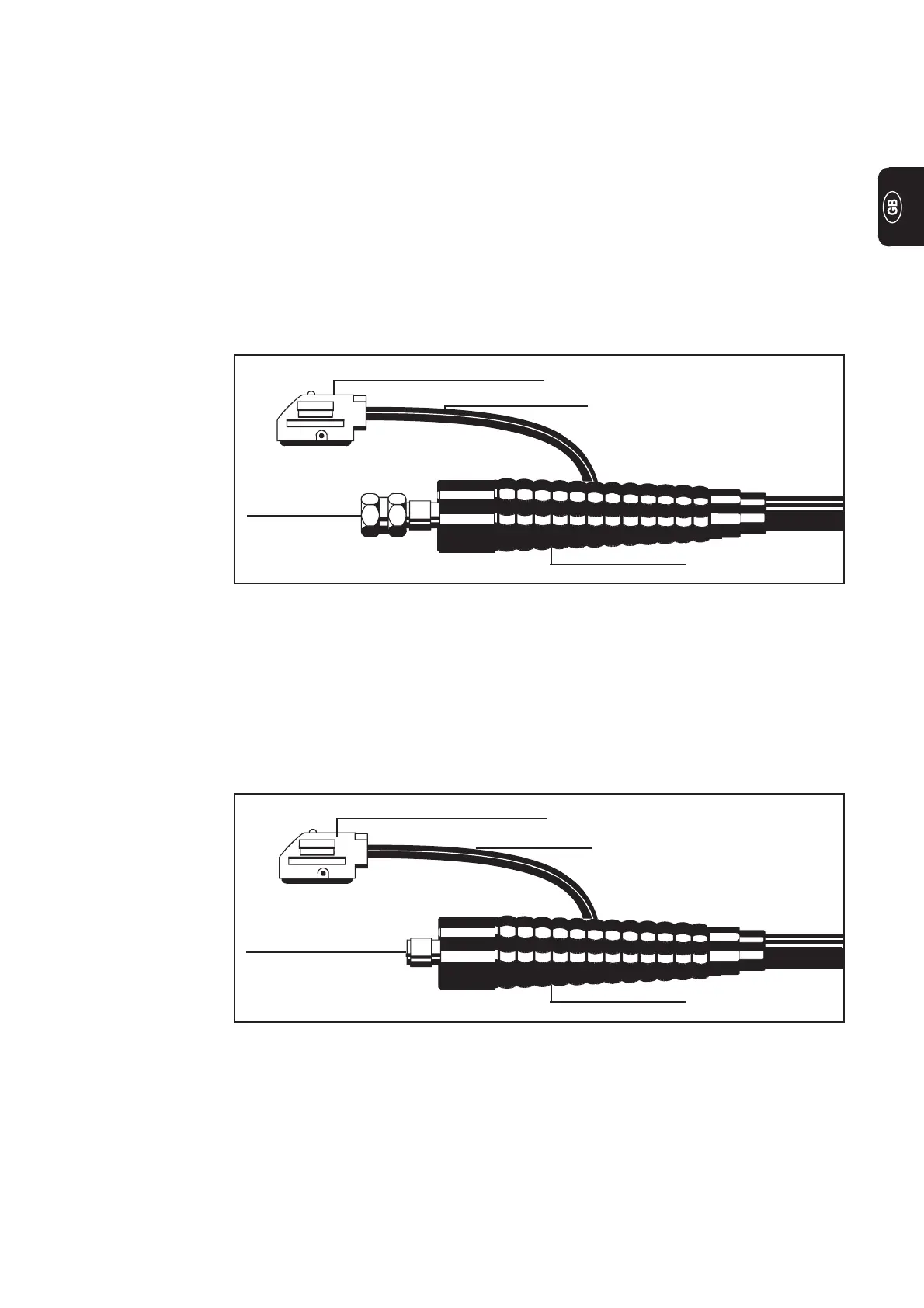

Design with

Fronius central

welding torch

connection F

Fig. 7 Design with Fronius central welding torch connection F: Torch connection gas-cooled

Gas and current

connection

Control plug

Control lead

Hose sleeve

Loading...

Loading...