12

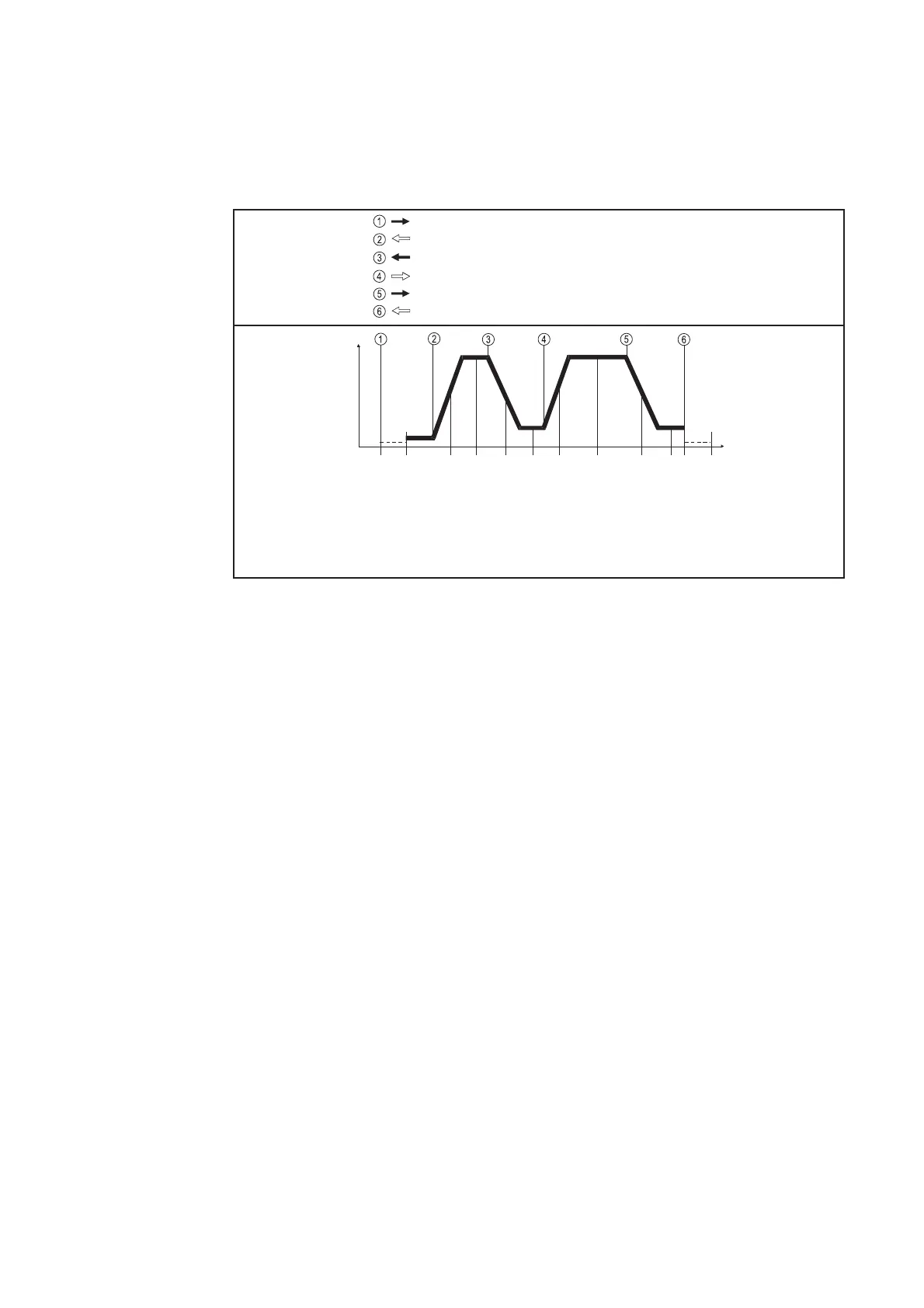

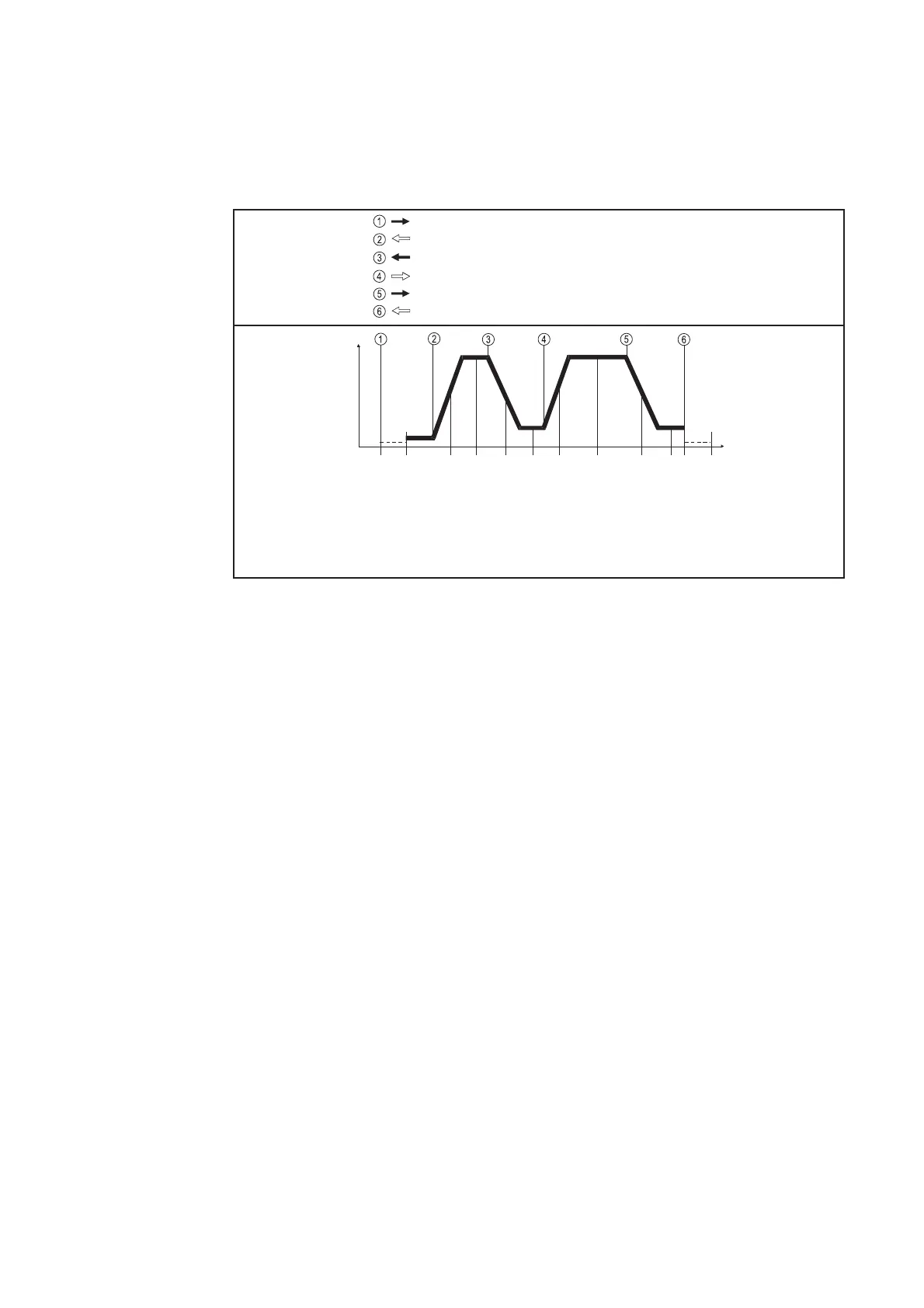

Fig. 12 Functional sequence in 4-step operating mode - Variant I - with intermediate lowering

- Activated from TIG torch trigger with double-pushbutton function

- Intermediate lowering to the reduced current I

E:

Welding current can be lowered

from the main current to the reduced current I

E

and back, without interrupting the

weld-ing sequence

- In the "PRESETTINGS LEVEL___" (see "Working with the program-levels"), TIG

parameters, SFS must be set to OFF

Important!

- Current reduction with no interruption to welding is only possible when the main

current is activated

- If the torch trigger is accidentally pushed forward in open circuit, no ignition cycle

takes place

Push trigger forward and hold it

Release the torch trigger

Release the torch trigger

Pull back and hold down the torch trigger once again

t

Pull back torch trigger and hold it down

Release the torch trigger

I

E

Gas post-flow time

End of welding

Crater-fill current I

E

I

S

I

H

I

E

I

I

H

Start of cycle

Gas pre-flow time

Current rise via up-slope

Current drop via

down-slope

Crater-fill current I

E

Arc ignition with start arc I

S

Welding with pre-set

main current I

H

Current rise via up-slope

Current drop via

down-slope

Welding with pre-set

main current I

H

4-step mode -

with intermediate

lowering

Loading...

Loading...