27

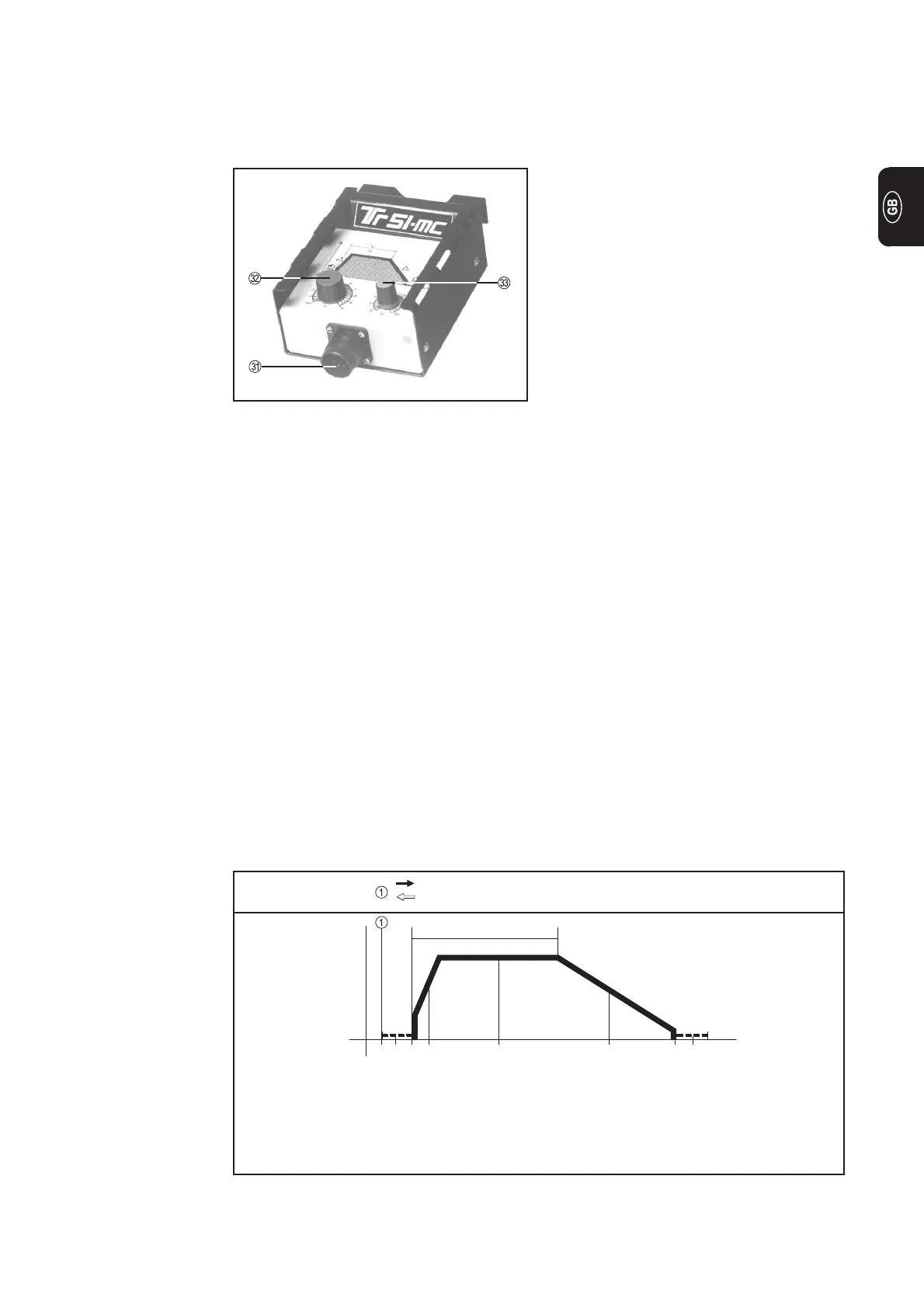

Fig. 28 TR 51mc remote control spot-welding unit

Standard welding of thin sheet metal constructions in such a way that they do not rust is

often not possible due to severe warping of the material. This is where spot welding

comes into its own. Similarly, problem welds, such as joins which are only accessible

from a single side, can easily be dealt with using the TIG spot-welding process.

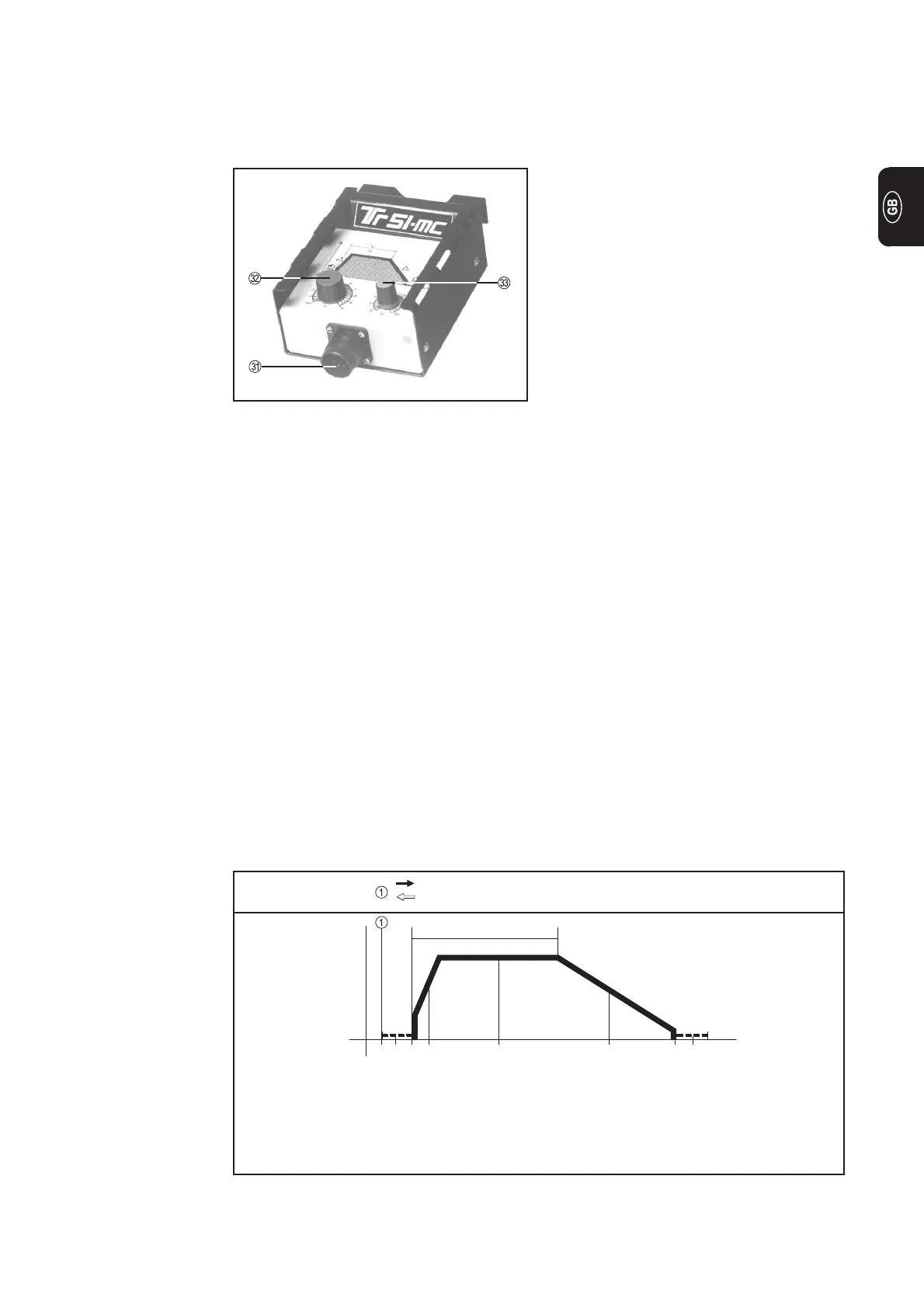

Fig. 29 Functional sequence with the TR 51mc remote control spot-welding unit

Connecting the remote control unit

- Link the connecting socket [G] on the

power source and the socket (31) on

the remote-control unit electrically

with the remote control cable.

- Plug in the plug-in connections the

right way round, and screw the

coupling ring on as far as possible.

TR 51mc remote

control spot-

welding unit

Functional description

- The machine automatically switches over to 2-step operation

- LED indicator (8) lights up

- The current drop time is set directly on the power source

- A special - insulated - spot-welding nozzle is used, which is mounted on the cone.

- Depending on the size of spot-weld required, mount the tungsten electrode approx.

2 - 3 mm back from the edge of the nozzle

- Set spot-welding current and time on the remote-control unit.

- Place the torch on the workpiece and gently press down onto the base material

- To carry out the spot-weld actuate the torch trigger. (Make sure there is no air-gap!)

The automatic spot-welding sequence is as follows

- Pull back and release the torch trigger.

- Gas pre-flow time elapses.

- Arc ignites with start-arc current.

- Current rises via the set up-slope to the spot-welding current value set on the dial

(32).

- The spot-welding time (0,1 - 8 secs.) set on the dial (33) elapses.

- The current drops via the down-slope (dial 11) to the final crater current.

- The gas post-flow time elapses.

Important! In the event of any trouble, the welder can manually interrupt the automatic

spot-welding sequence by pulling back and releasing the trigger again!

t

H

Pull back and

Release the torch trigger

Gas pre-flow time

Arc ignition

Start of cycle

I

H

End of welding

Gas post-flow time

Current-rise via

up-slope

Current-drop

via down-slope

Spot-welding with set

welding current I

H

in conjunction with

spot-welding time t

H

t

O

I

Loading...

Loading...