28

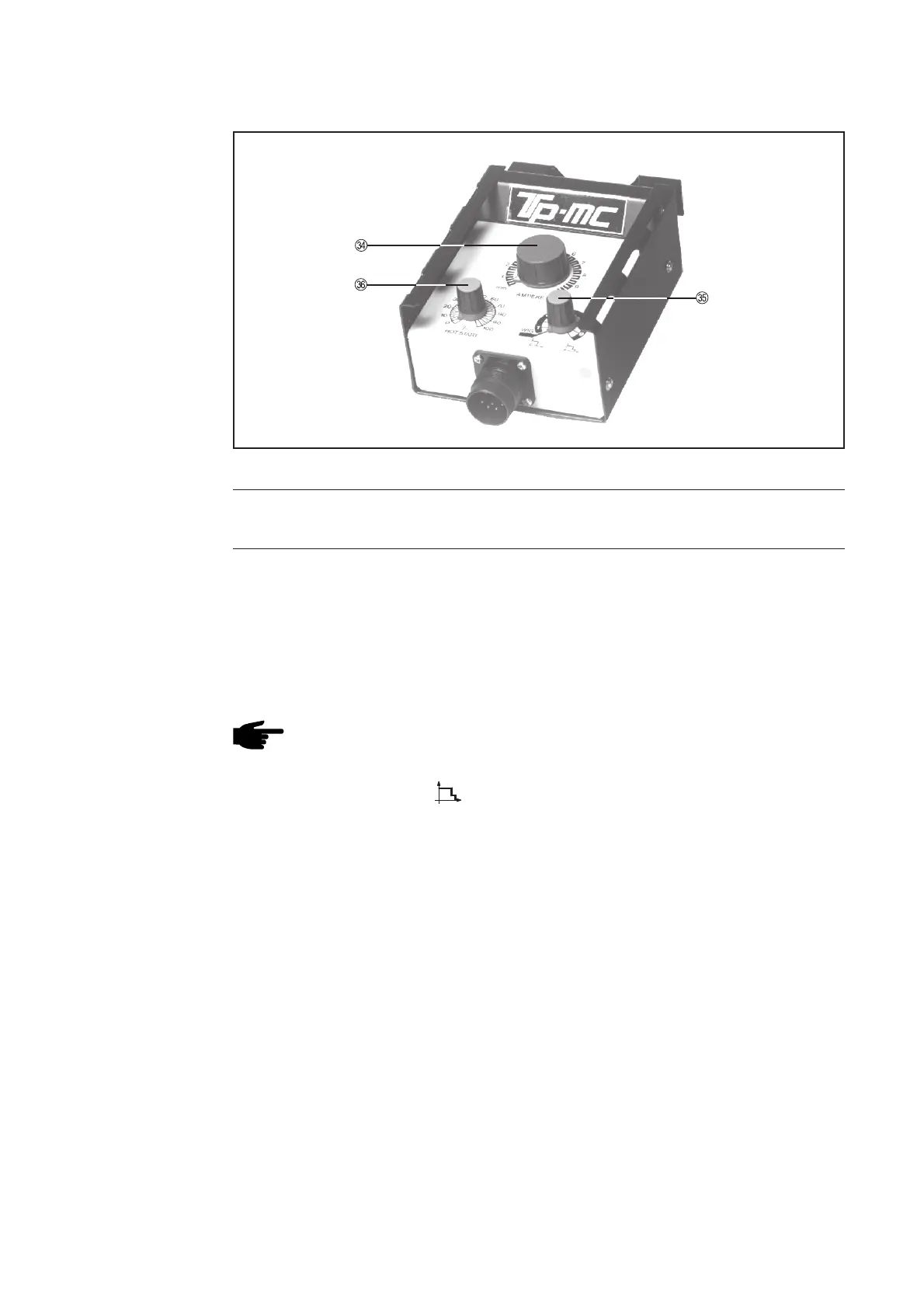

TPmc remote

control unit

This workplace remote control unit is intended for use in particular with manual electrode

and TIG welding.

Fig. 30 TPmc remote control unit

(34) Welding current dial

- for continuous adjustment of the welding current

(35) Arc force control dial

- influences the short circuit amperage at the moment of drop transfer (from

electrode to workpiece)

At scale setting "0" there is no increase at all in the short circuit amperage at the

moment of drop transfer (soft arc).

Range of application: welding using rutile electrodes (fine globules), basic shea-

thed electrodes in the medium and upper amperage ranges

NOTE! When welded at low load, basic-sheathed electrodes tend to "GET

STUCK" on the workpiece.

At scale setting "10" there is a very considerable in-crease in amperage at

the moment of drop transfer (hard arc).

Range of application: Basic sheathed electrodes (coarse-globule), when these are

to be welded in the lower amperage range (vertical-up seams, edge hardfacing

welds, root welding etc.)

Important! When the setting on the arc force control dial is adjusted upwards, the

following may be observed when rutile, basic-sheathed or special electrodes are

being used:

- easy ignition

- reduction in welding misfires

- less electrode burn-on

- good root penetration

- occasionally an increase in spattering

- when welding thin sheet metal the danger of "burning through" increases

Loading...

Loading...