13

- Enables the 4-step mode to be activated from TIG torch triggers without the double-

pushbutton function

- ZIntermediate lowering to the reduced current I

3

(for details of how to set this, see

"Working with the program-levels")

- Welding current can be lowered from the main current to the reduced current I

3

and

back, without interrupting the welding sequence

- In the "PRESETTINGS LEVEL___" program level (see "Working with the program-

levels"), Parameter I3, the reduced current I3 can be set as a percentage of the

main current I

H

- In the "PRESETTINGS LEVEL___" (see "Working with the program-levels"), TIG

parameters, SFS must be set to 1

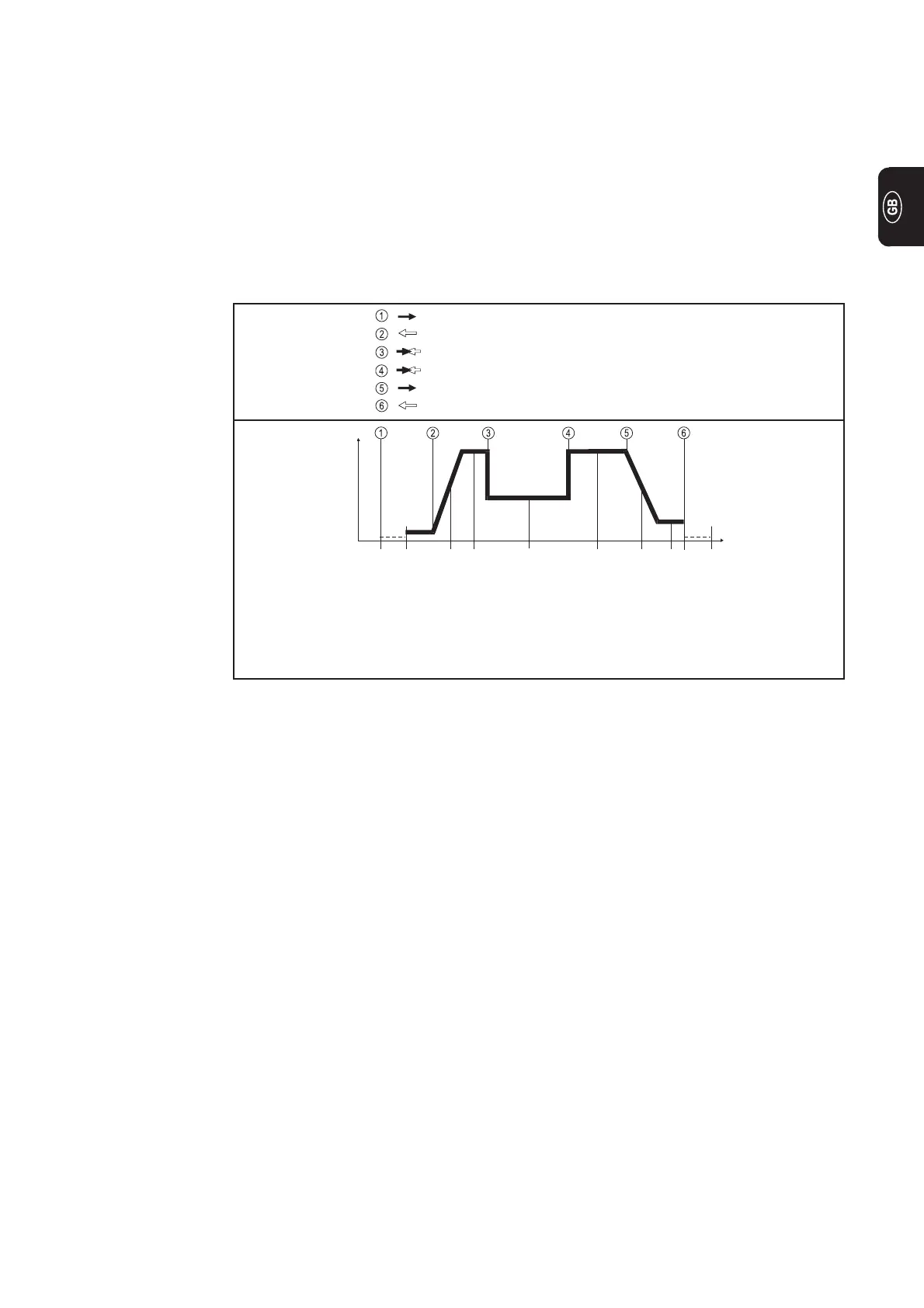

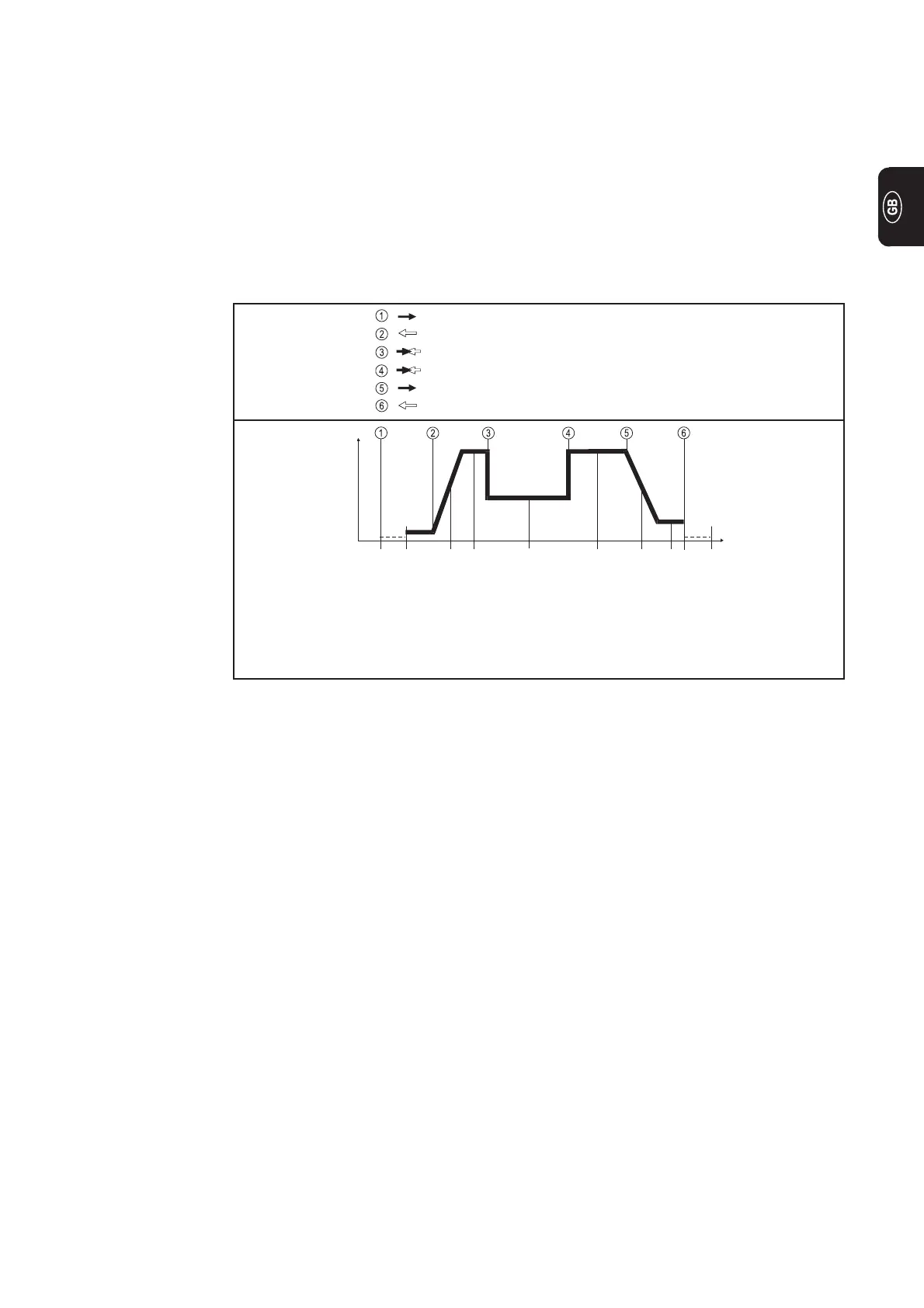

Fig. 13 Functional sequence in special 4-step mode - Variant I

briefly press the torch trigger (forward)

briefly press the torch trigger (forward)

Release the torch trigger

Pull back torch trigger and hold it down

I

S

I

H

I

3

I

t

Pull back torch trigger and hold it down

Release the torch trigger

I

E

I

H

Start of cycle

Gas pre-flow time

Current rise via up-slope

Gas post-flow time

End of welding

Welding with pre-set

lowering current I

3

(Setup)

Arc ignition with start arc I

S

Welding with pre-set

main current I

H

Current drop via

down-slope

Welding with pre-set

main current I

H

Crater-fill current I

E

Diagram showing intermediate lowering

Special 4-step

mode - Variant I

Loading...

Loading...