13

ENGLISH

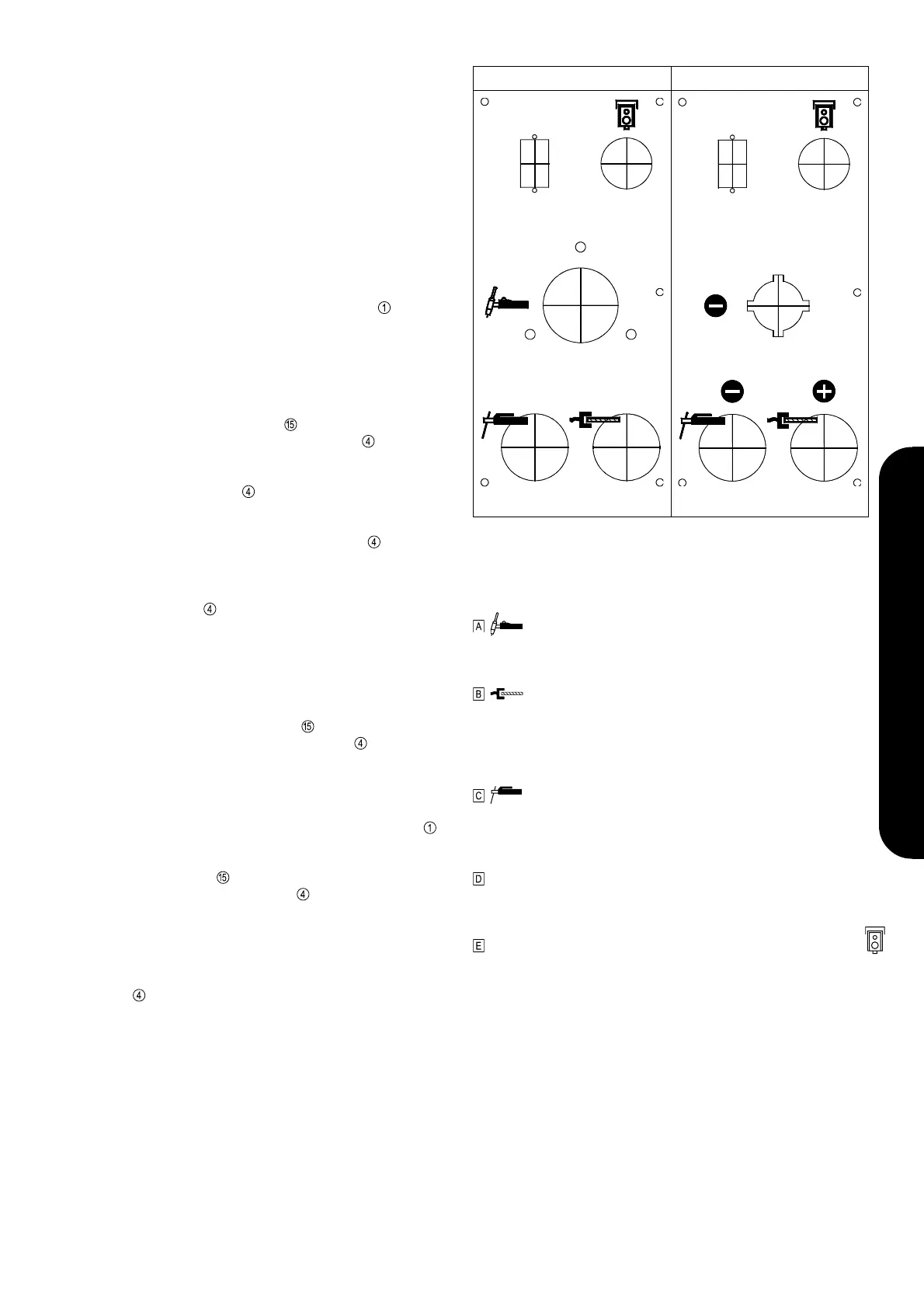

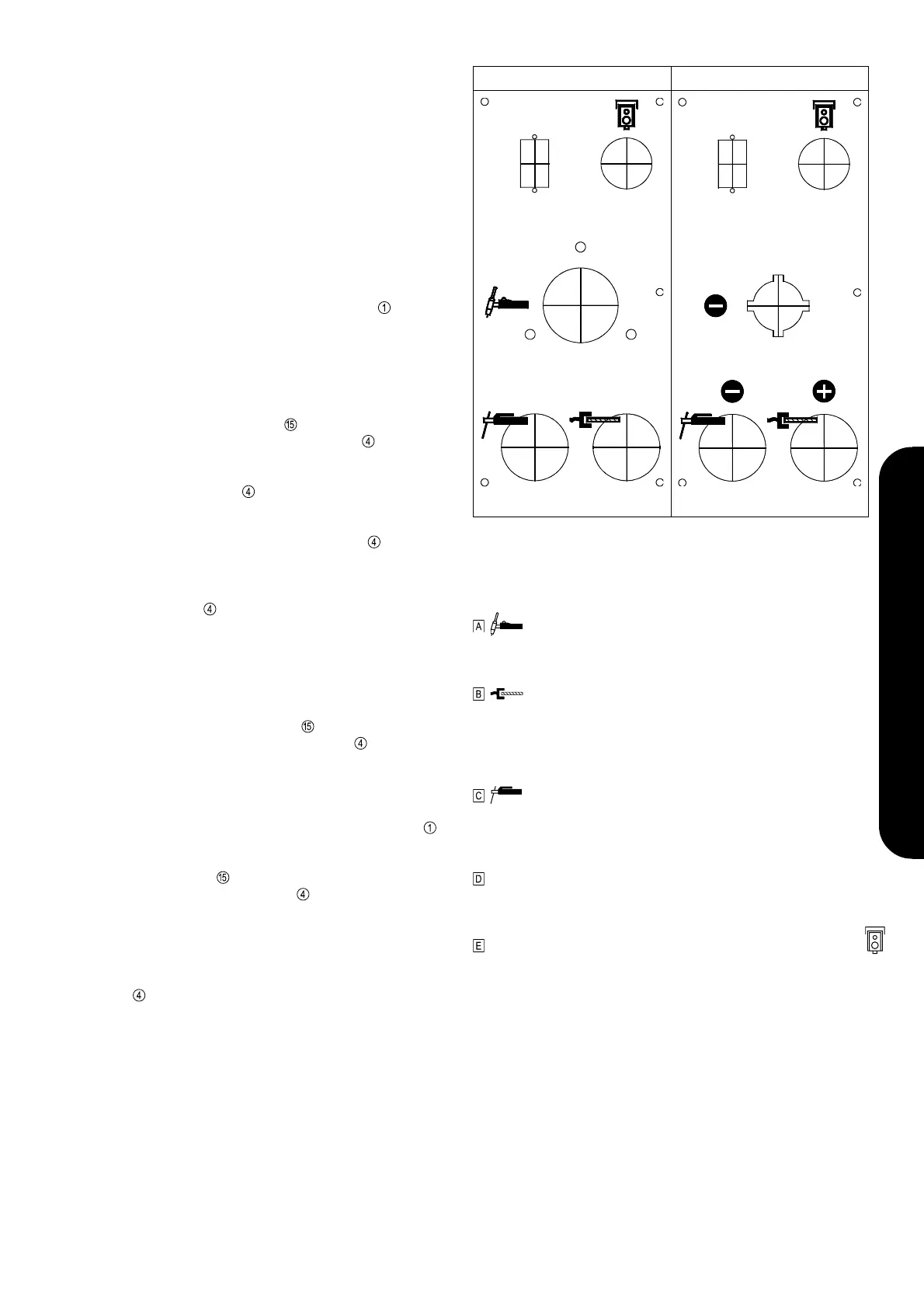

TIG torch connection (gas cooled)

- for connecting the central GAS + CURRENT supply for the

welding torch

SOCKET with bayonet coupling, serves:

a) as the earth cable connection point with TIG welding;

b) as the connection either for the manual electrode cable or

the earth cable with manual electrode welding, depending

on the type of electrode used.

SOCKET with bayonet coupling, serves:

- as the connection either for the manual electrode cable or

the earth cable with manual electrode welding, depending

on the type of electrode used.

TORCH CONTROL SOCKET

- Plug in the control plug for the welding torch, and latch in

place.

CONNECTING SOCKET (10-pole) for remote control unit

- Plug the remote control cable plug into the socket, the right

way round, and tighten the swivel nut

- The machine automatically recognizes the fact that the

remote control unit has been plugged in - there is thus no

need for any internal/external switchover.

- The short-circuit-proof supply voltage to the remote control

units protects the electronics in the event of any damage to

the remote control cable.

- The desired welding current is set on the remote control unit.

2.3 Level 1:

- Service menu with various test programs.

2.4 Level 2:

Codelock: The MW 2000 Fuzzy and Transtig 2000 machi-

nes come with an electronic codelock.

General:

a) The codelock is not activated when the machines leave

the factory.

b) Whenever you change the numerical combination, keep

a written note of it!

c) If the wrong combination is entered 3 times in a row, the

machine switches off automatically and can only be re-

started by turning the mains master switch

OFF and

then ON.

Altering the codelock and switching it on/off:

- Access program level 2, as described in Pt. 1 above

- Enter the existing 3-digit code number:

(on new machines, this is set to “321”).

Use the main current (I

H

) dial to enter the digits from 0-

9. Confirm each digit with selector switch until your 3-

digit combination is complete.

- To change the code number

Use selector switch to move to each digit of the

combination in turn, entering a new digit from 0-9 by

pushing the torch trigger forward. After you have entered

the new combination, use selector switch to move to

the “Cod ON/OFF” point. The codelock can now be

switched on or off with the torch trigger. Either ON or OFF

will appear on the display. Move on to “PRO” by pressing

selector switch .

- PRO (program): For programming the code parame-

ters

(numerical combination plus code ON or OFF).

Push the torch trigger forwards. The machine then asks

you to enter the altered code again. Now enter the new

combination - this code will now be stored in the memory.

Using the main current (I

H

) dial , enter digits from 0-9.

Confirm each digit with selector switch . If the wrong

combination is entered 3 times in a row, the machine

switches off automatically, as described in c) above.

Machine start-up when codelock is activated:

- Switch on the machine at the mains master switch .

The display immediately shows “Cod”, requesting you to

enter the code-number.

- Using the I

H

dial , enter the combination, confirming

each digit with selector switch .

- Once you have entered the 3-digit combination in this

way, the machine is ready for use.

2.5 Level 3 (only on AC machines!):

All parameters can be selected with the function selector

switch

, and altered with the torch trigger.

- ACF AC frequency 40 - 100 Hz

(in “Electrode” and TIG modes)

- POS Positive half-wave (tri, SIN, rEC) only in TIG mode

- nEG Negative half-wave (tri, SIN, rEC) only in TIG mode

- PRO (Program): For storing the parameters that have

been set, by pushing the torch trigger forward.

[tri (=triangle), SIN (=sinus), rEC (=square-wave)]

Fig. 11 Torch / welding-cable connection points on front of machine

MAGIC WAVE 2000 Fuzzy TRANSTIG 2000

Loading...

Loading...