12

b) DC-operation:

- Is used to set the ignition current for the diameter of tung-

sten electrode in question.

When the machine is in the “Electrode" modes, adjustment

dial

is inactive.

SELECTOR SWITCH for TYPE OF CURRENT:

/ /

This is used for selecting the type of current required, and for

reversing the polarity with both TIG and ROD ELECTRODE

MANUAL WELDING.

Functional description:

1. : (=> TIG welding of unalloyed, low and high alloy

steels, Sn or Cu bronzes, copper etc.)

a) TIG mode => LED or lights up

- Minus pole is on the tungsten electrode

b) MAN.ELECTRODE mode => LED lights up

- Minus pole is on the rod electrode

2. : (=direct current => special TIG welding)

a) TIG mode= LED or lights up

- The minus pole is on the tungsten electrode

Warning! An electronic interlocking, fitted as standard,

prevents the plus-pole from being switched to the tungsten

electrode in the TIG mode, as this would overload and

damage the electrode.

b) MANUAL ELECTRODE mode => LED lights up

- The plus pole is on the rod electrode

(interlocking is automatically made inoperative).

3. (=alternating current, TIG welding of aluminium

and its alloys, aluminium-bronze etc.)

a) TIG mode => LED or lights up

- Alternating current is on the tungsten electrode

b) MANUAL ELECTRODE mode => LED lights up

- Alternating current is on the rod electrode

The following parameters are laid down by an internal program:

- Gas pre-flow time ............... 0.4 sec

- Start arc:

36 % of I

H

in DC mode

50 % of I

H

in AC mode

- Up-slope ............................. 1.0 sec

- Gas post-flow time .............. 5 - 15 sec, dep. on amperage

- Frequency .......................... 60 Hz

All parameters can be changed individually, via a program menu.

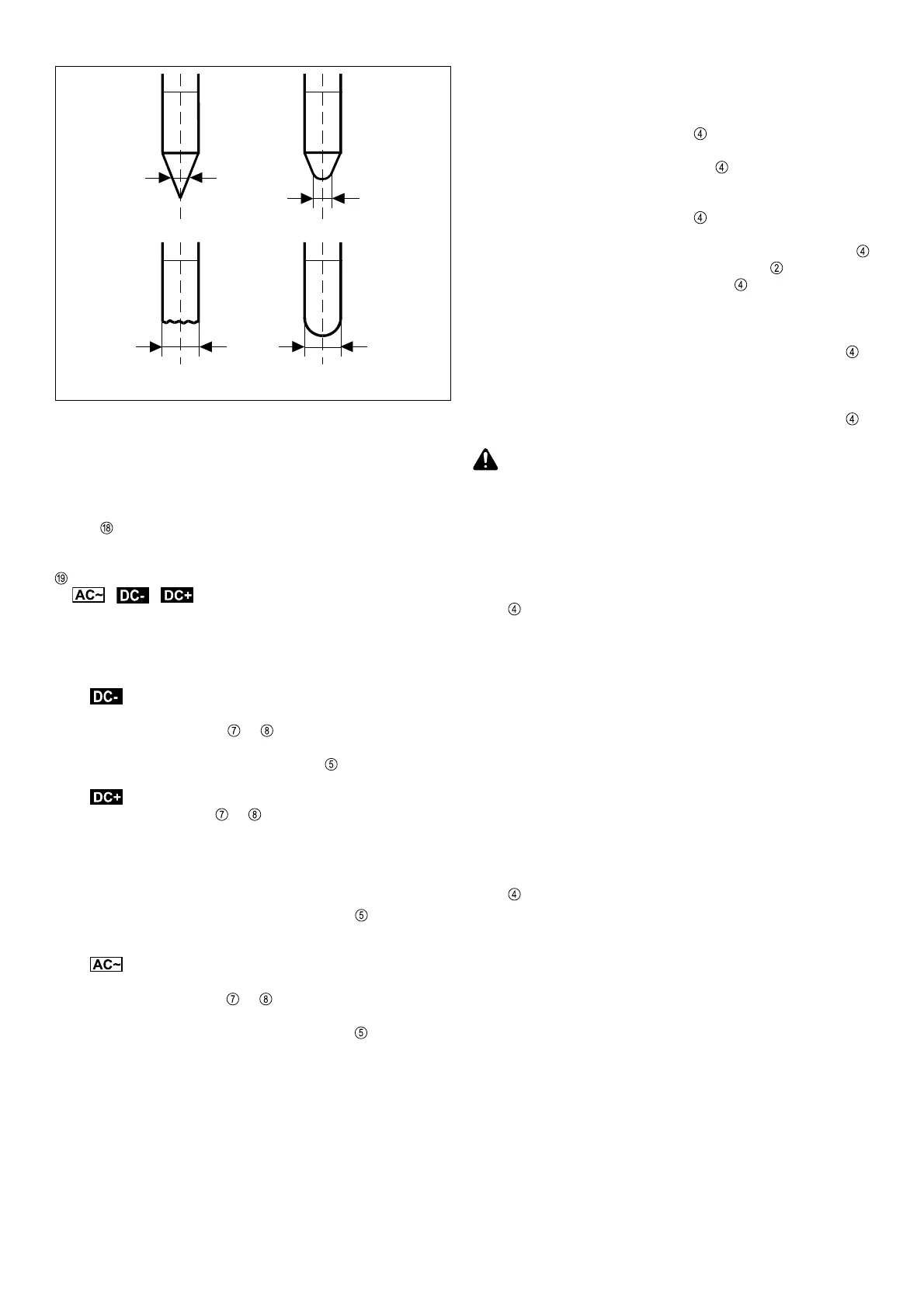

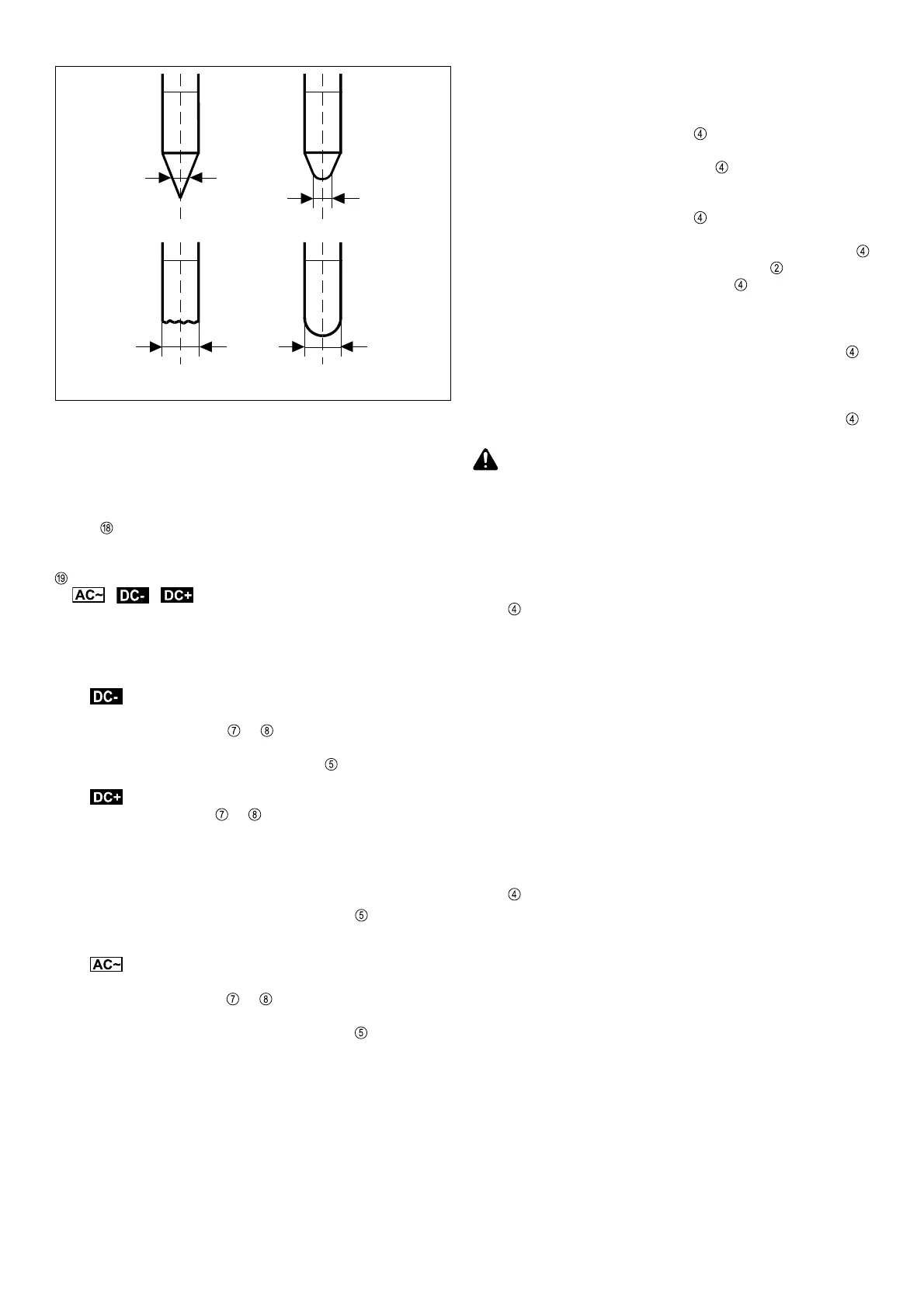

Fig. 10 Diagram showing formation of spherical tip

after ignition

before ignition

1. ACCESSING THE VARIOUS PROGRAM

LEVELS

1.1 Pre-setting level:

Press function selector switch

, switching the machine on

at the same time. As soon as 3 lines appear in the display,

stop pressing the selector switch

.

1.2 Level 1:

Press function selector switch

, switching the machine on

at the same time. As soon as 3 lines appear in the displays,

press the torch trigger once, keeping the selector switch

pressed. “P1” will appear on the ammeter .

-> Stop pressing the selector switch

1.3 Level 2:

Proceed as for Level 1, but press the torch trigger twice.

Display shows “P2”. Stop pressing the selector switch .

1.4 Level 3:

Proceed as for Level 1, but press the torch trigger 3 times.

Display shows “P3”. Stop pressing the selector switch .

Caution! Before you access the pre-setting level (as per 1.1

above), check whether the machine is in the “TIG” or “Elec-

trode” mode. The parameters shown will be those for the

operating mode in which the machine happens to be.

2. PARAMETERS

2.1 TIG pre-setting level:

All parameters can be selected with function selector switch

, and then changed with the torch trigger.

- GAS Gas pre-flow 0.2 - 2 sec

- G-L Gas post-flow at I

min

2.0 - 26 sec

- G-H Gas post-flow at I

max

2.0 - 26 sec

- UPS Up-slope 0.2 - 7 sec

- SCU Starter current

(start arc 10 - 100 % in DC, 30 - 100 % in AC)

- I3 Reduced current, 0-100% of I

H

- StS Special 2-step mode ON/OFF

- SFS Special-4-step mode OFF/1/2

- PRO (Program): For storing the parameters, once these

have been set, by pressing the torch trigger forward.

- FAC (Factory): For activating the parameters pre-set by

Fronius, by pressing the torch trigger forward.

2.2 “Electrode” pre-setting level

All parameters can be selected with function selector switch

, and then changed with the torch trigger.

- Hti Hotstart time 0.2 - 2 sec

- HCU Hotstart current 0 - 100 %

- dYn Arcforce dynamic 0 - 100 A

- PRO (Program): For storing the parameters, once these

have been set, by pressing the torch trigger forward.

- FAC (Factory): For activating the parameters pre-set by

Fronius, by pressing the torch trigger forward.

- In the “Electrode AC” mode, the applicable frequency is

the one set in Level 3. The waveform in “Electrode AC” is

generally a square-wave one.

Parameters of the pre-set Fronius program:

GAS 0,4sec Hti 0,5sec

G-L 5,0sec HCU 50%

G-H 15,0sec dyn 30A

UPS 1,0sec ACF 60Hz

SCU DC 36% POS sin

AC 50% nEG rEC

SFS OFF I3 50%

StS OFF

Loading...

Loading...