8-6 239 Motor Protection Relay GE Multilin

8 TESTING 8 TESTING

8

8.8 SWITCH INPUT

1. To verify the operation of each 239 switch input, go to

$ 67$786?6:,7&+ 67$786 and with the

and

keys, view the status of each switch input one at a time. Open and close

each switch input and note that the display reflects the present status of the input terminals. Ver-

ify the results with the table below.

8.9 ANALOG OUTPUT

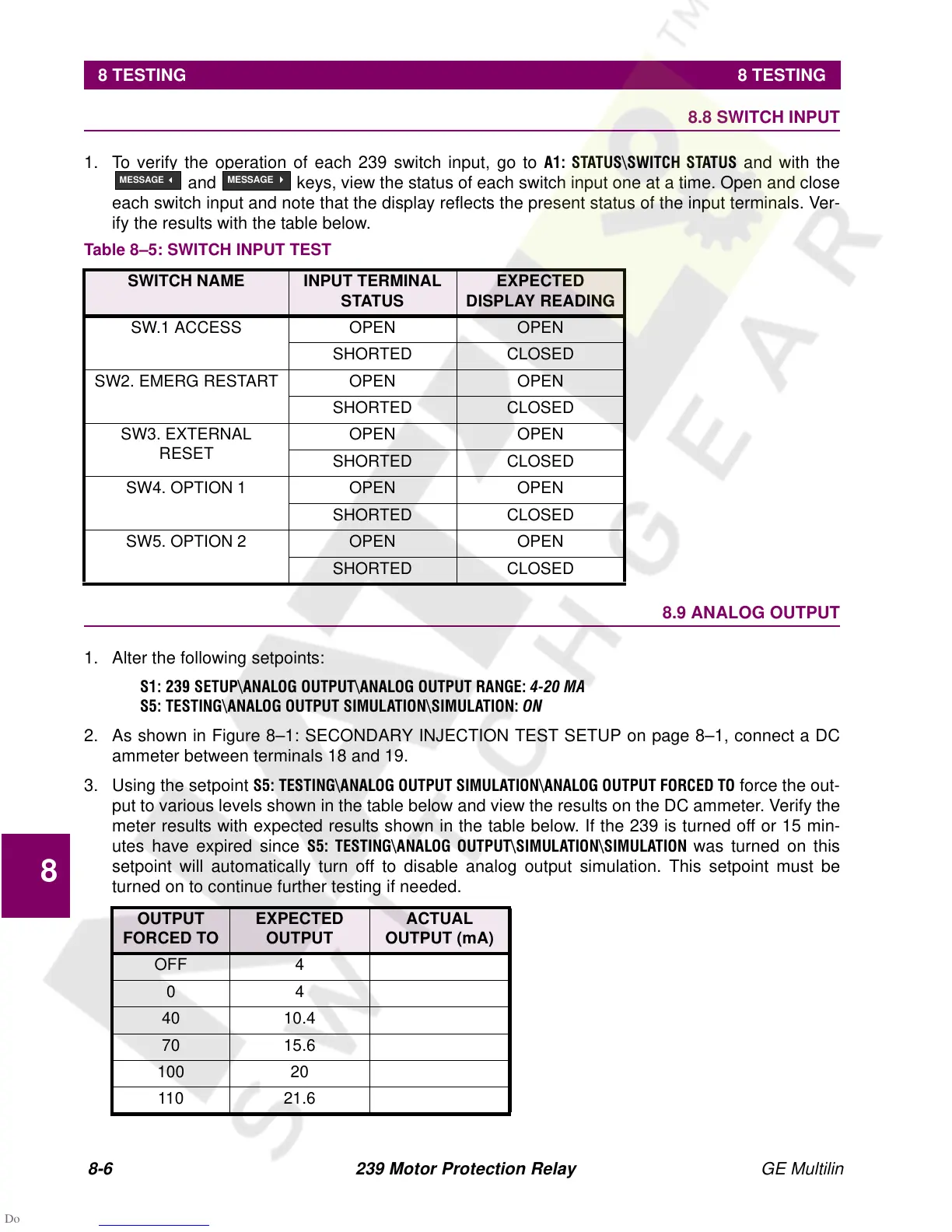

1. Alter the following setpoints:

66(783?$1$/2*287387?$1$/2*2873875$1*(0$

67(67,1*?$1$/2*2873876,08/$7,21?6,08/$7,2121

2. As shown in Figure 8–1: SECONDARY INJECTION TEST SETUP on page 8–1, connect a DC

ammeter between terminals 18 and 19.

3. Using the setpoint

67(67,1*?$1$/2*2873876,08/$7,21?$1$/ 2*287387)25&('72 force the out-

put to various levels shown in the table below and view the results on the DC ammeter. Verify the

meter results with expected results shown in the table below. If the 239 is turned off or 15 min-

utes have expired since

6 7(67,1*?$1$/2* 287387?6,08/$7,21?6,08/$7,21 was turned on this

setpoint will automatically turn off to disable analog output simulation. This setpoint must be

turned on to continue further testing if needed.

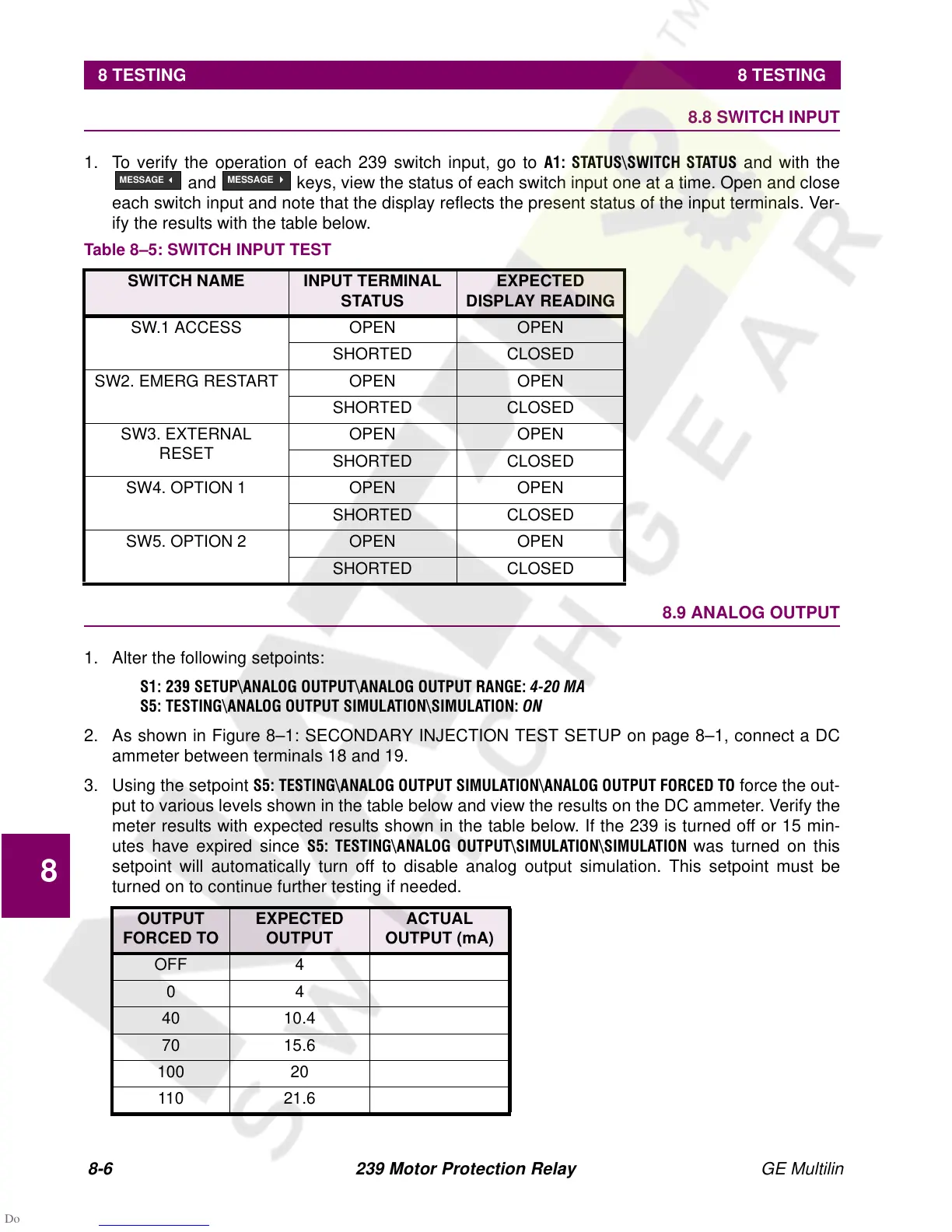

Table 8–5: SWITCH INPUT TEST

SWITCH NAME INPUT TERMINAL

STATUS

EXPECTED

DISPLAY READING

SW.1 ACCESS OPEN OPEN

SHORTED CLOSED

SW2. EMERG RESTART OPEN OPEN

SHORTED CLOSED

SW3. EXTERNAL

RESET

OPEN OPEN

SHORTED CLOSED

SW4. OPTION 1 OPEN OPEN

SHORTED CLOSED

SW5. OPTION 2 OPEN OPEN

SHORTED CLOSED

OUTPUT

FORCED TO

EXPECTED

OUTPUT

ACTUAL

OUTPUT (mA)

OFF 4

04

40 10.4

70 15.6

100 20

110 21.6

MESSAGE

3

MESSAGE

4

Loading...

Loading...