GE Multilin 239 Motor Protection Relay iii

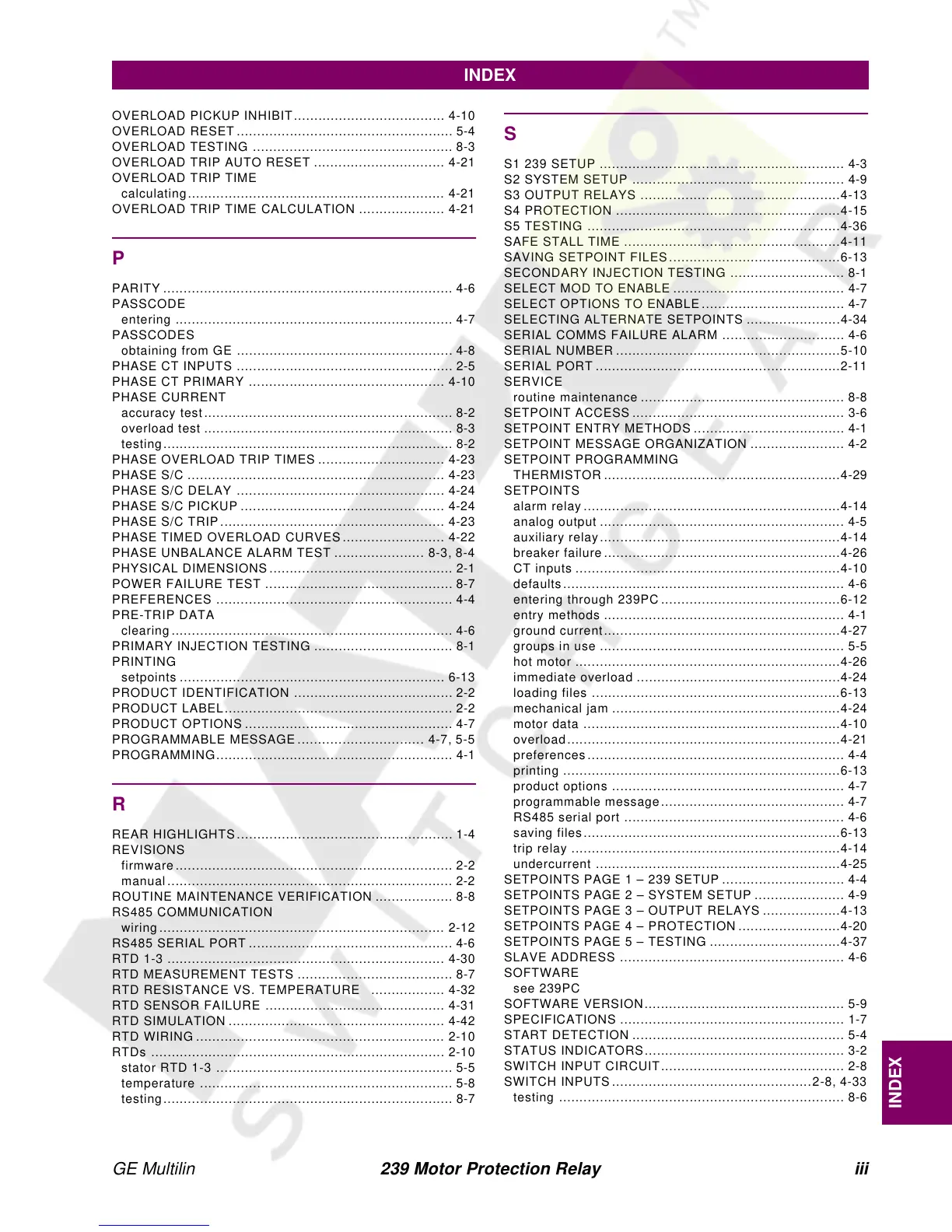

INDEX

INDEX

OVERLOAD PICKUP INHIBIT..................................... 4-10

OVERLOAD RESET..................................................... 5-4

OVERLOAD TESTING ................................................. 8-3

OVERLOAD TRIP AUTO RESET ................................ 4-21

OVERLOAD TRIP TIME

calculating............................................................... 4-21

OVERLOAD TRIP TIME CALCULATION ..................... 4-21

P

PARITY ....................................................................... 4-6

PASSCODE

entering .................................................................... 4-7

PASSCODES

obtaining from GE ..................................................... 4-8

PHASE CT INPUTS ..................................................... 2-5

PHASE CT PRIMARY ................................................ 4-10

PHASE CURRENT

accuracy test............................................................. 8-2

overload test ............................................................. 8-3

testing....................................................................... 8-2

PHASE OVERLOAD TRIP TIMES ............................... 4-23

PHASE S/C ............................................................... 4-23

PHASE S/C DELAY ................................................... 4-24

PHASE S/C PICKUP .................................................. 4-24

PHASE S/C TRIP....................................................... 4-23

PHASE TIMED OVERLOAD CURVES......................... 4-22

PHASE UNBALANCE ALARM TEST ...................... 8-3, 8-4

PHYSICAL DIMENSIONS............................................. 2-1

POWER FAILURE TEST .............................................. 8-7

PREFERENCES .......................................................... 4-4

PRE-TRIP DATA

clearing..................................................................... 4-6

PRIMARY INJECTION TESTING .................................. 8-1

PRINTING

setpoints ................................................................. 6-13

PRODUCT IDENTIFICATION ....................................... 2-2

PRODUCT LABEL........................................................ 2-2

PRODUCT OPTIONS ................................................... 4-7

PROGRAMMABLE MESSAGE............................... 4-7, 5-5

PROGRAMMING.......................................................... 4-1

R

REAR HIGHLIGHTS..................................................... 1-4

REVISIONS

firmware.................................................................... 2-2

manual...................................................................... 2-2

ROUTINE MAINTENANCE VERIFICATION ................... 8-8

RS485 COMMUNICATION

wiring...................................................................... 2-12

RS485 SERIAL PORT .................................................. 4-6

RTD 1-3 .................................................................... 4-30

RTD MEASUREMENT TESTS ...................................... 8-7

RTD RESISTANCE VS. TEMPERATURE .................. 4-32

RTD SENSOR FAILURE ............................................ 4-31

RTD SIMULATION ..................................................... 4-42

RTD WIRING ............................................................. 2-10

RTDs ........................................................................ 2-10

stator RTD 1-3 .......................................................... 5-5

temperature .............................................................. 5-8

testing....................................................................... 8-7

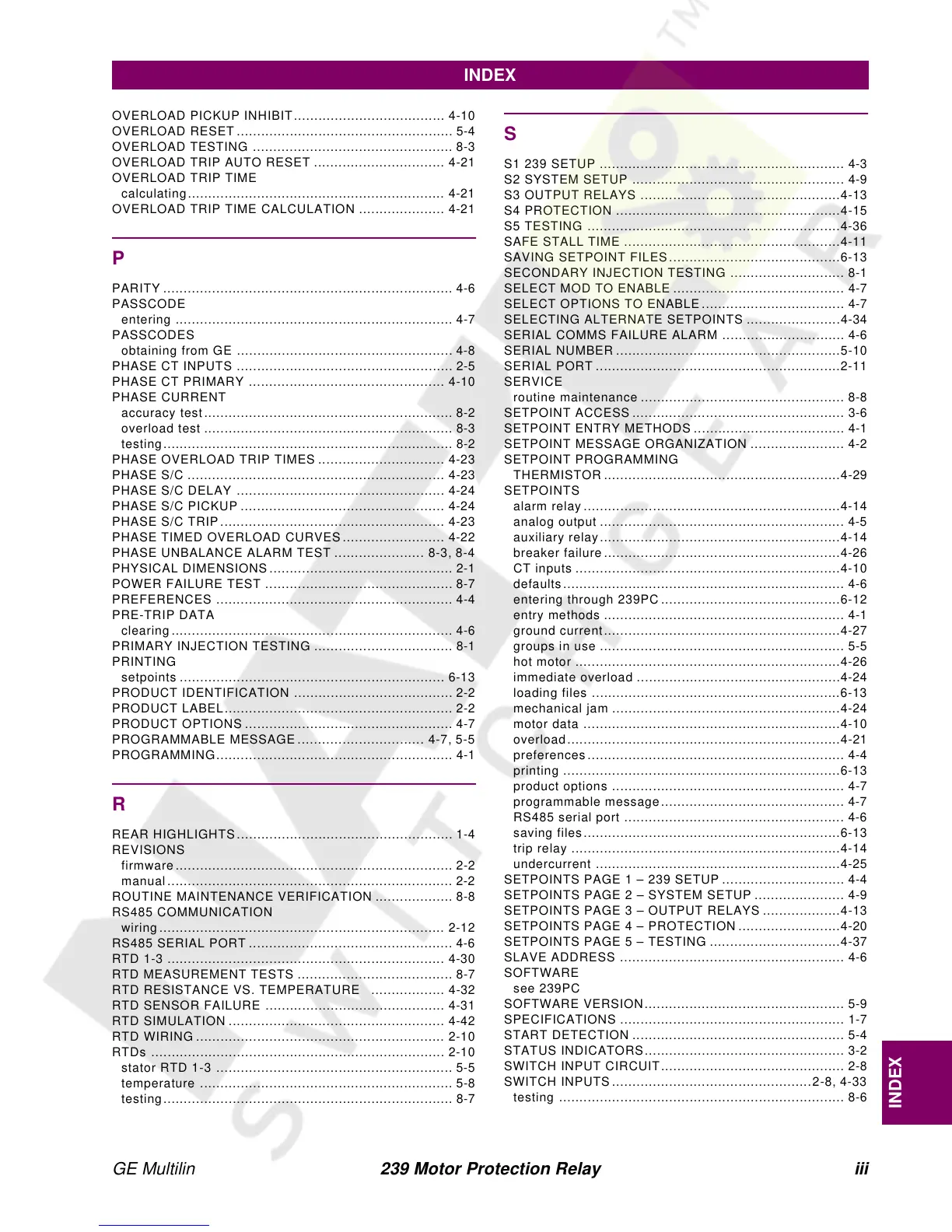

S

S1 239 SETUP ............................................................ 4-3

S2 SYSTEM SETUP .................................................... 4-9

S3 OUTPUT RELAYS .................................................4-13

S4 PROTECTION .......................................................4-15

S5 TESTING ..............................................................4-36

SAFE STALL TIME .....................................................4-11

SAVING SETPOINT FILES..........................................6-13

SECONDARY INJECTION TESTING ............................ 8-1

SELECT MOD TO ENABLE .......................................... 4-7

SELECT OPTIONS TO ENABLE................................... 4-7

SELECTING ALTERNATE SETPOINTS .......................4-34

SERIAL COMMS FAILURE ALARM .............................. 4-6

SERIAL NUMBER .......................................................5-10

SERIAL PORT ............................................................2-11

SERVICE

routine maintenance .................................................. 8-8

SETPOINT ACCESS .................................................... 3-6

SETPOINT ENTRY METHODS ..................................... 4-1

SETPOINT MESSAGE ORGANIZATION ....................... 4-2

SETPOINT PROGRAMMING

THERMISTOR ..........................................................4-29

SETPOINTS

alarm relay...............................................................4-14

analog output ............................................................ 4-5

auxiliary relay...........................................................4-14

breaker failure..........................................................4-26

CT inputs .................................................................4-10

defaults..................................................................... 4-6

entering through 239PC............................................6-12

entry methods ........................................................... 4-1

ground current..........................................................4-27

groups in use ............................................................ 5-5

hot motor .................................................................4-26

immediate overload ..................................................4-24

loading files .............................................................6-13

mechanical jam ........................................................4-24

motor data ...............................................................4-10

overload...................................................................4-21

preferences............................................................... 4-4

printing ....................................................................6-13

product options ......................................................... 4-7

programmable message............................................. 4-7

RS485 serial port ...................................................... 4-6

saving files...............................................................6-13

trip relay ..................................................................4-14

undercurrent ............................................................4-25

SETPOINTS PAGE 1 – 239 SETUP .............................. 4-4

SETPOINTS PAGE 2 – SYSTEM SETUP ...................... 4-9

SETPOINTS PAGE 3 – OUTPUT RELAYS ...................4-13

SETPOINTS PAGE 4 – PROTECTION.........................4-20

SETPOINTS PAGE 5 – TESTING ................................4-37

SLAVE ADDRESS ....................................................... 4-6

SOFTWARE

see 239PC

SOFTWARE VERSION................................................. 5-9

SPECIFICATIONS ....................................................... 1-7

START DETECTION .................................................... 5-4

STATUS INDICATORS................................................. 3-2

SWITCH INPUT CIRCUIT............................................. 2-8

SWITCH INPUTS.................................................2-8, 4-33

testing ...................................................................... 8-6

Loading...

Loading...