4-6 735/737 Feeder Protection Relay

GE Power Management

4.2 SUPPORTED MODBUS FUNCTIONS 4 MODBUS COMMUNICATIONS

4

4.2.4 FUNCTION CODE 05: EXECUTE OPERATION

Modbus Implementation: Force Single Coil

735/737 Implementation: Execute Operation

This function code allows the master to request the 735/737 to perform specific operations. The operations that can be

performed by the 735/737 are as follows:

Simulation and I/O test commands are for production testing and training simulation. Commands 02 - 07 will be ignored

unless communications "TEST" switch 8 is on. When a REMOTE SETTINGS command is received (TEST switch=on) the

front panel switch settings are replaced by the dial settings loaded into setpoint memory. Send command NORMAL SET-

TINGS to restore selection of front panel dial settings. If command SIMULATION ON is sent the actual phase and ground

current are replaced by the pre-loaded values in setpoint memory. The relay will respond as if these are the actual dial set-

tings and measured current values. This mode continues until power is lost or until the command "SIMULATION OFF" is

received or TEST switch 8 is set to off. Setpoints used in this mode are stored in RAM memory and are erased when con-

trol power is lost. The relay may behave erratically if invalid values are loaded into setpoint memory.

To turn on relays, LEDs and the bargraph under computer control for testing purposes, the appropriate I/O test patterns are

first loaded as setpoints using STORE SETPOINTS function 06 or 16. Then command "TEST I/O ON" is issued. Normal

relay control of this I/O hardware is suspended and the test patterns in setpoint memory are substituted. This continues

until a "TEST I/O OFF" command is received or control power is removed or TEST switch 8=off.

During testing, normal protection is disabled. As a safeguard, all test and simulation commands are ignored unless switch 8

is in the TEST on=1 position.

Message Format and Example:

Request slave 11 to execute operation code 1 (clear trip indicators).

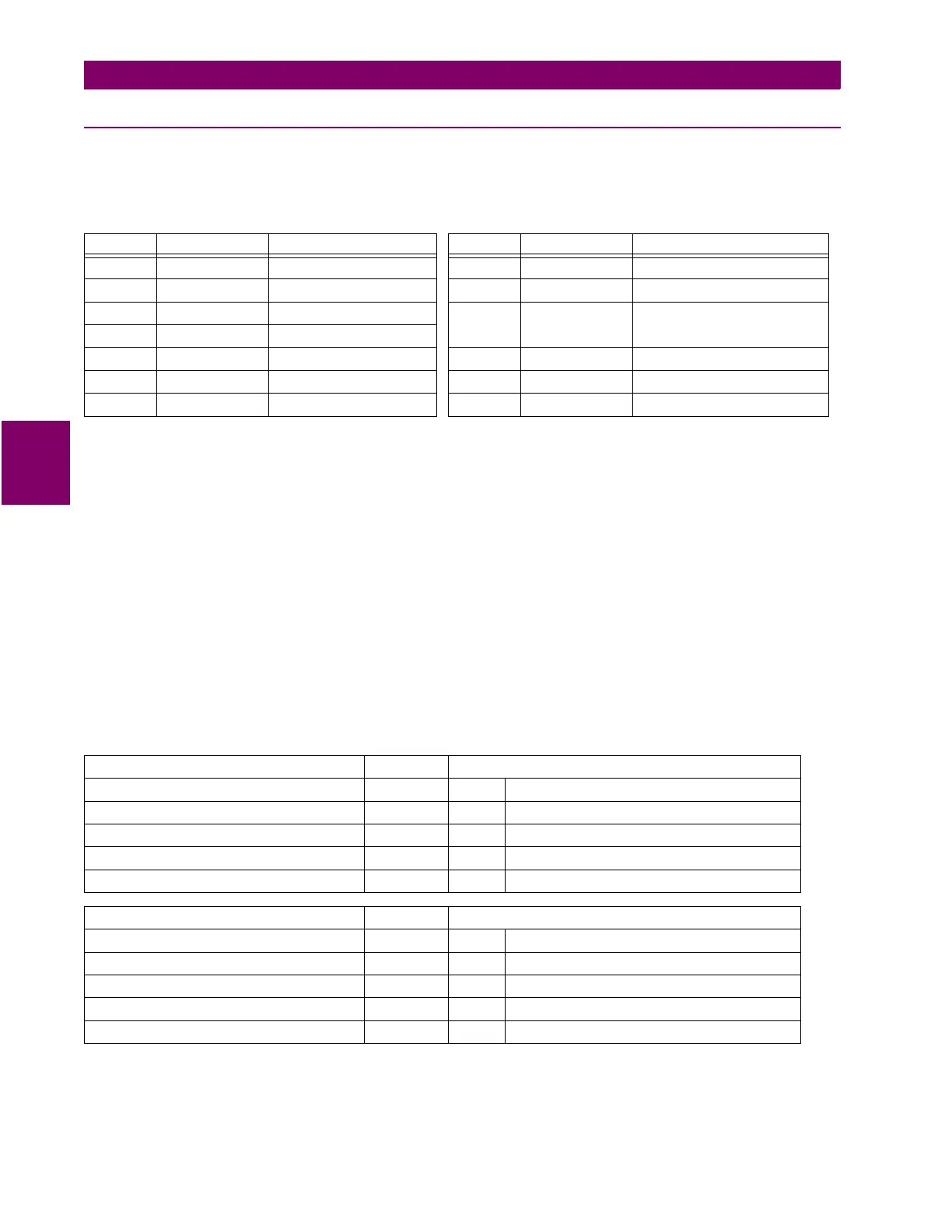

OPCODE FUNCTION DESCRIPTION OPCODE FUNCTION DESCRIPTION

01 clear clear trip indicators 08 disable watchdog reset main processor

02 remote settings simulation dials 09 enable service activate service relay & indicator

03 normal settings front panel dials 0A disable service deactivate service relay &

indicator

04 simulation on simulation currents

05 simulation off actual currents 0B disable relays disable output relays

06 test I/O on setpoint control of I/O 0C enable relays enable output relays

07 test I/O off normal control of I/O 0D clear last trips clear 5 causes of last trips

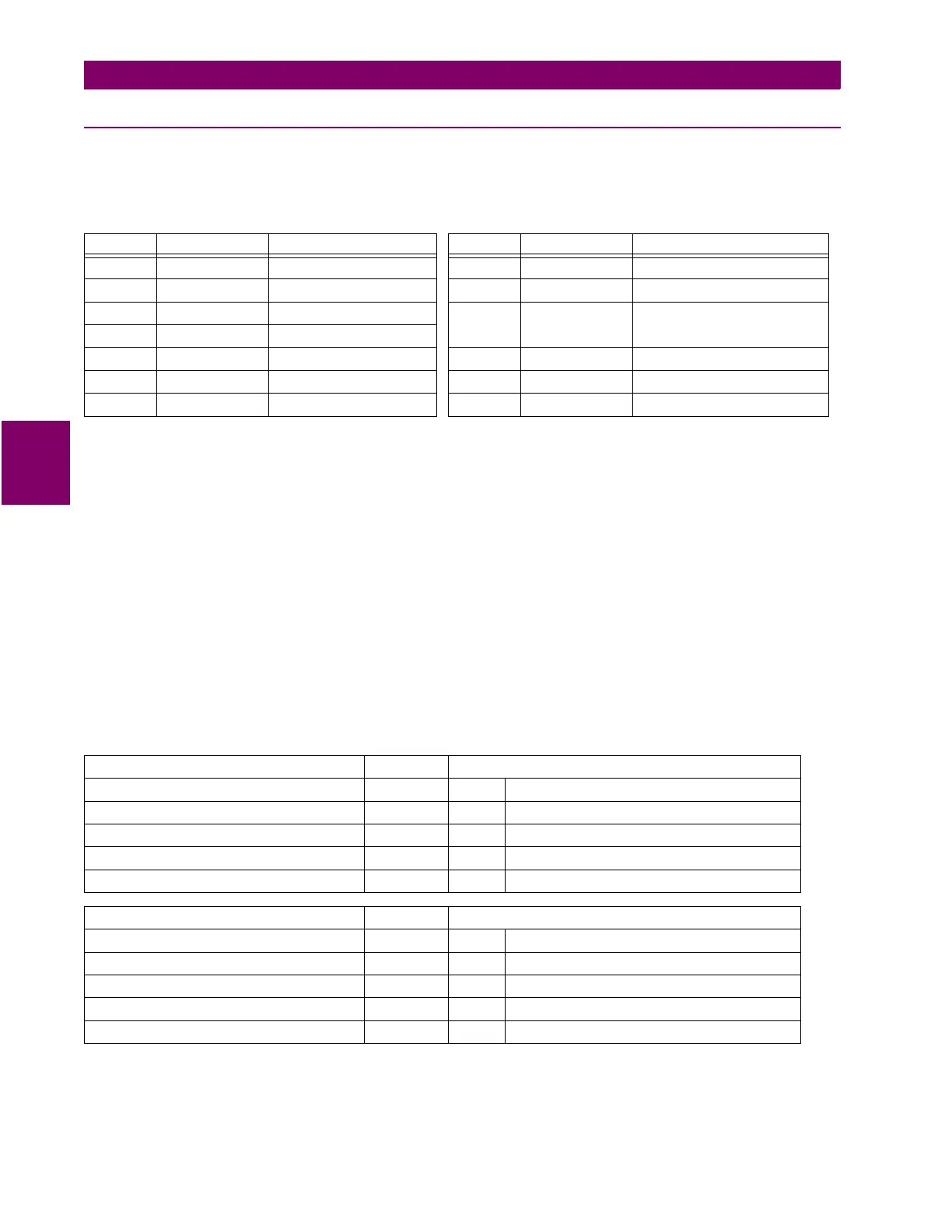

MASTER TRANSMISSION: BYTES EXAMPLE / DESCRIPTION

SLAVE ADDRESS 1 11 message for slave 11

FUNCTION CODE 1 05 execute operation

OPERATION CODE 2 00 01 operation code 1 = clear trip indicators

CODE VALUE 2 FF 00 perform function

CRC 2 ?? ?? CRC calculated by the master

SLAVE RESPONSE: BYTES EXAMPLE / DESCRIPTION

SLAVE ADDRESS 1 11 response message from slave 11

FUNCTION CODE 1 05 execute operation

OPERATION CODE 2 00 01 operation code 1 = clear trip indicators

CODE VALUE 2 FF 00 perform function

CRC 2 ?? ?? CRC calculated by the slave

Loading...

Loading...