5-6 735/737 Feeder Protection Relay

GE Power Management

5.2 ANSI CURVES 5 OVERCURRENT CURVES

5

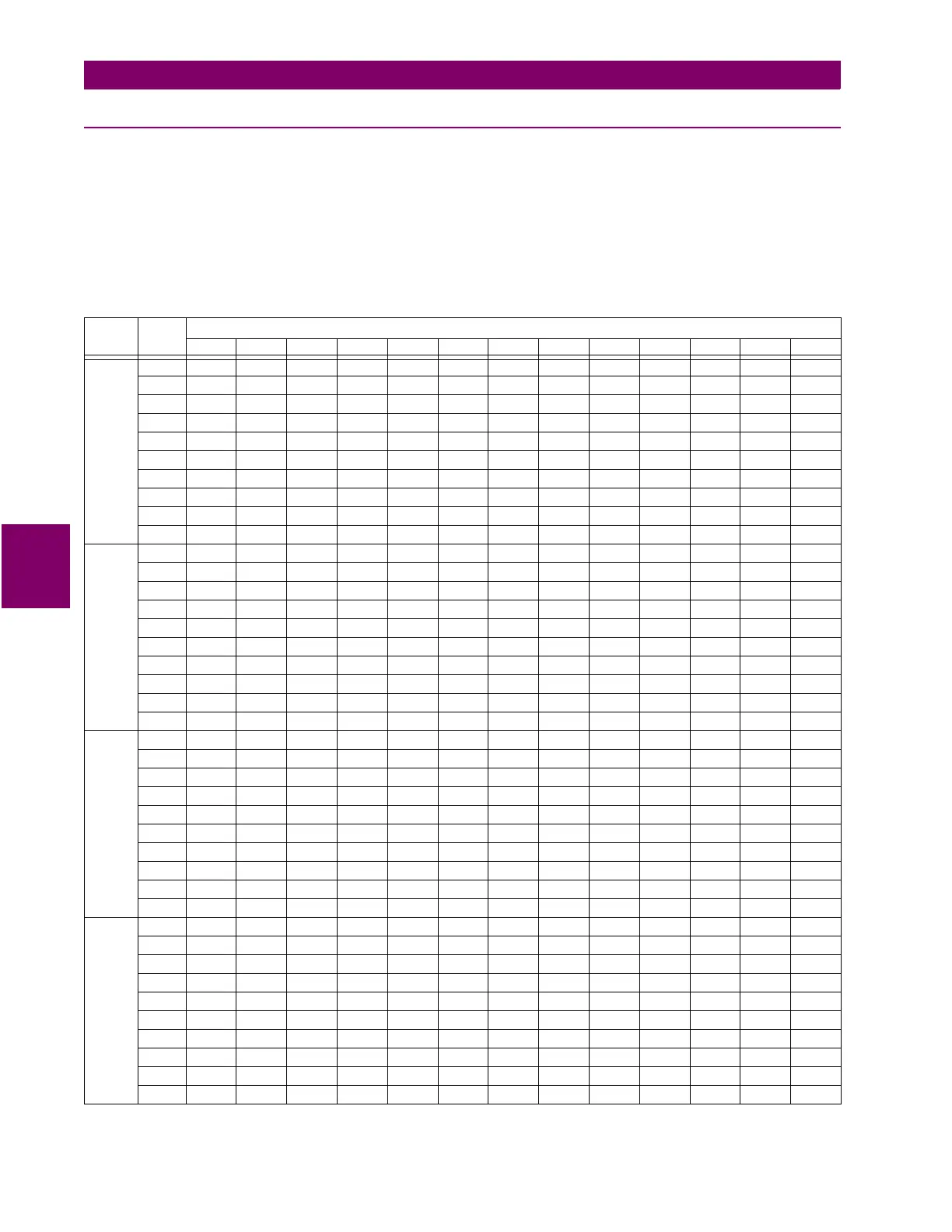

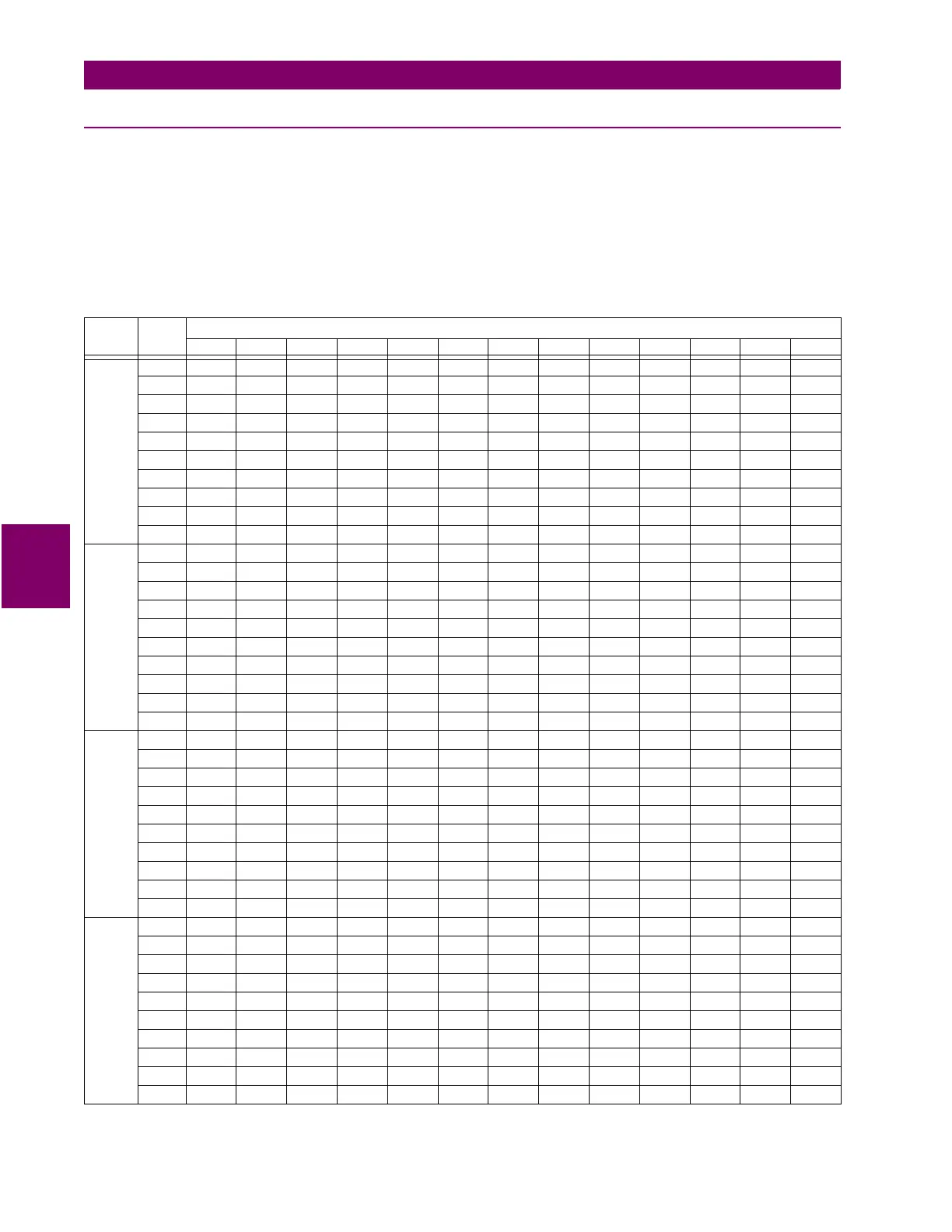

5.2.3 ANSI VERY INVERSE CURVES

The trip time is given by:

where: T = trip time (in seconds) A = 0.0615 (curve shape constant)

S = curve shift multiplier B = 0.7989 (curve shape constant)

M = 735/737 curve multiplier setpoint C = 0.3400 (curve shape constant)

I = input current (in amps) D = –0.2840 (curve shape constant)

Ipu = pickup current setpoint E = 4.0505 (curve shape constant)

SHIFT

S

CURVE

M

CURRENT (per unit I /I

0

)

1.05 1.50 2.00 3.00 4.00 5.00 6.00 7.00 8.00 9.00 10.00 15.00 20.00

1 1 11.940 3.134 1.325 0.537 0.341 0.260 0.216 0.189 0.170 0.156 0.146 0.116 0.102

2 23.881 6.268 2.650 1.074 0.682 0.520 0.432 0.378 0.340 0.312 0.291 0.232 0.204

3 35.821 9.402 3.976 1.611 1.024 0.780 0.648 0.566 0.510 0.469 0.437 0.348 0.306

4 47.762 12.537 5.301 2.148 1.365 1.040 0.864 0.755 0.680 0.625 0.583 0.464 0.408

5 59.702 15.671 6.626 2.685 1.706 1.299 1.081 0.944 0.850 0.781 0.728 0.580 0.510

6 71.642 18.805 7.951 3.221 2.047 1.559 1.297 1.133 1.020 0.937 0.874 0.696 0.612

7 83.583 21.939 9.276 3.758 2.388 1.819 1.513 1.321 1.190 1.093 1.020 0.812 0.714

8 95.523 25.073 10.602 4.295 2.730 2.079 1.729 1.510 1.360 1.250 1.165 0.928 0.815

9 107.464 28.207 11.927 4.832 3.071 2.339 1.945 1.699 1.530 1.406 1.311 1.044 0.917

10 119.404 31.341 13.252 5.369 3.412 2.599 2.161 1.888 1.700 1.562 1.457 1.160 1.019

0.5 1 5.970 1.567 0.663 0.268 0.171 0.130 0.108 0.094 0.085 0.078 0.073 0.058 0.051

2 11.940 3.134 1.325 0.537 0.341 0.260 0.216 0.189 0.170 0.156 0.146 0.116 0.102

3 17.911 4.701 1.988 0.805 0.512 0.390 0.324 0.283 0.255 0.234 0.218 0.174 0.153

4 23.881 6.268 2.650 1.074 0.682 0.520 0.432 0.378 0.340 0.312 0.291 0.232 0.204

5 29.851 7.835 3.313 1.342 0.853 0.650 0.540 0.472 0.425 0.391 0.364 0.290 0.255

6 35.821 9.402 3.976 1.611 1.024 0.780 0.648 0.566 0.510 0.469 0.437 0.348 0.306

7 41.791 10.969 4.638 1.879 1.194 0.910 0.756 0.661 0.595 0.547 0.510 0.406 0.357

8 47.762 12.537 5.301 2.148 1.365 1.040 0.864 0.755 0.680 0.625 0.583 0.464 0.408

9 53.732 14.104 5.963 2.416 1.535 1.169 0.973 0.849 0.765 0.703 0.655 0.522 0.459

10 59.702 15.671 6.626 2.685 1.706 1.299 1.081 0.944 0.850 0.781 0.728 0.580 0.510

0.8 1 9.552 2.507 1.060 0.430 0.273 0.208 0.173 0.151 0.136 0.125 0.117 0.093 0.082

2 19.105 5.015 2.120 0.859 0.546 0.416 0.346 0.302 0.272 0.250 0.233 0.186 0.163

3 28.657 7.522 3.180 1.289 0.819 0.624 0.519 0.453 0.408 0.375 0.350 0.278 0.245

4 38.209 10.029 4.241 1.718 1.092 0.832 0.692 0.604 0.544 0.500 0.466 0.371 0.326

5 47.762 12.537 5.301 2.148 1.365 1.040 0.864 0.755 0.680 0.625 0.583 0.464 0.408

6 57.314 15.044 6.361 2.577 1.638 1.247 1.037 0.906 0.816 0.750 0.699 0.557 0.489

7 66.866 17.551 7.421 3.007 1.911 1.455 1.210 1.057 0.952 0.875 0.816 0.649 0.571

8 76.418 20.058 8.481 3.436 2.184 1.663 1.383 1.208 1.088 1.000 0.932 0.742 0.652

9 85.971 22.566 9.541 3.866 2.457 1.871 1.556 1.359 1.224 1.125 1.049 0.835 0.734

10 95.523 25.073 10.602 4.295 2.730 2.079 1.729 1.510 1.360 1.250 1.165 0.928 0.815

1.1 1 13.134 3.448 1.458 0.591 0.375 0.286 0.238 0.208 0.187 0.172 0.160 0.128 0.112

2 26.269 6.895 2.915 1.181 0.751 0.572 0.475 0.415 0.374 0.344 0.320 0.255 0.224

3 39.403 10.343 4.373 1.772 1.126 0.858 0.713 0.623 0.561 0.515 0.481 0.383 0.336

4 52.538 13.790 5.831 2.362 1.501 1.144 0.951 0.831 0.748 0.687 0.641 0.510 0.449

5 65.672 17.238 7.289 2.953 1.877 1.429 1.189 1.038 0.935 0.859 0.801 0.638 0.561

6 78.807 20.685 8.746 3.544 2.252 1.715 1.426 1.246 1.122 1.031 0.961 0.765 0.673

7 91.941 24.133 10.204 4.134 2.627 2.001 1.664 1.453 1.309 1.203 1.122 0.893 0.785

8 105.075 27.580 11.662 4.725 3.003 2.287 1.902 1.661 1.496 1.375 1.282 1.020 0.897

9 118.210 31.028 13.119 5.315 3.378 2.573 2.140 1.869 1.683 1.546 1.442 1.148 1.009

10 131.344 34.475 14.577 5.906 3.753 2.859 2.377 2.076 1.870 1.718 1.602 1.276 1.121

TSMA

B

II

pu

⁄()

C

–

----------------------------

D

II

pu

⁄()

C

–

()

2

-----------------------------------

E

II

pu

⁄()

C

–

()

3

-----------------------------------

++ +

××

=

Loading...

Loading...