4-8 735/737 Feeder Protection Relay

GE Power Management

4.2 SUPPORTED MODBUS FUNCTIONS 4 MODBUS COMMUNICATIONS

4

4.2.7 FUNCTION CODE 16: STORE MULTIPLE SETPOINTS

Modbus Implementation: Preset Multiple Registers

735/737 Implementation: Store Multiple Setpoints

This function code allows multiple setpoints to be stored into the 735/737 memory for test purposes only. Modbus "regis-

ters" are 16 bit (two byte) values transmitted high order byte first. Thus all 735/737 setpoints are sent as two bytes. The

slave device response to this function code is to echo the slave address, function code, starting address, the number of set-

points loaded, and the CRC.

For production testing and training simulation without a current source, setpoint values can be loaded into RAM. These are

lost at power down. Using the multiple setpoints store command, phase and ground dial setting setpoints are first stored in

memory. Simulated values for phase and ground current can also be loaded.

To enter simulation mode, "TEST" switch #8 must be on. Function code 05 execute operation sends command "SIMULA-

TION ON". If test switch 8 is off, this command is ignored. On receipt of the "SIMULATION ON" command values for phase

and ground current from setpoint memory replace the actual measured currents.

The relay responds as if these current were actually being measured. If execute operation command "REMOTE SET-

TINGS" is also sent, front panel dial settings will be replaced by the previously sent dial setpoints. These values continue to

be used until control power is removed or commands "SIMULATION OFF" and "NORMAL SETTINGS" is received or TEST

switch 8=off.

Setpoint test patterns can also be stored for forcing relays and LEDs and the bargraph to test outputs. Using this setpoint

store command the test pattern is first stored. The Execute Operation function 05 command "TEST I/O ON" is issued. The

LEDs, relays and bargraph are driven by the test patterns stored in setpoints instead of relay control until command "TEST

I/O OFF" is received, control power is lost or TEST switch 8=off.

Message Format and Example:

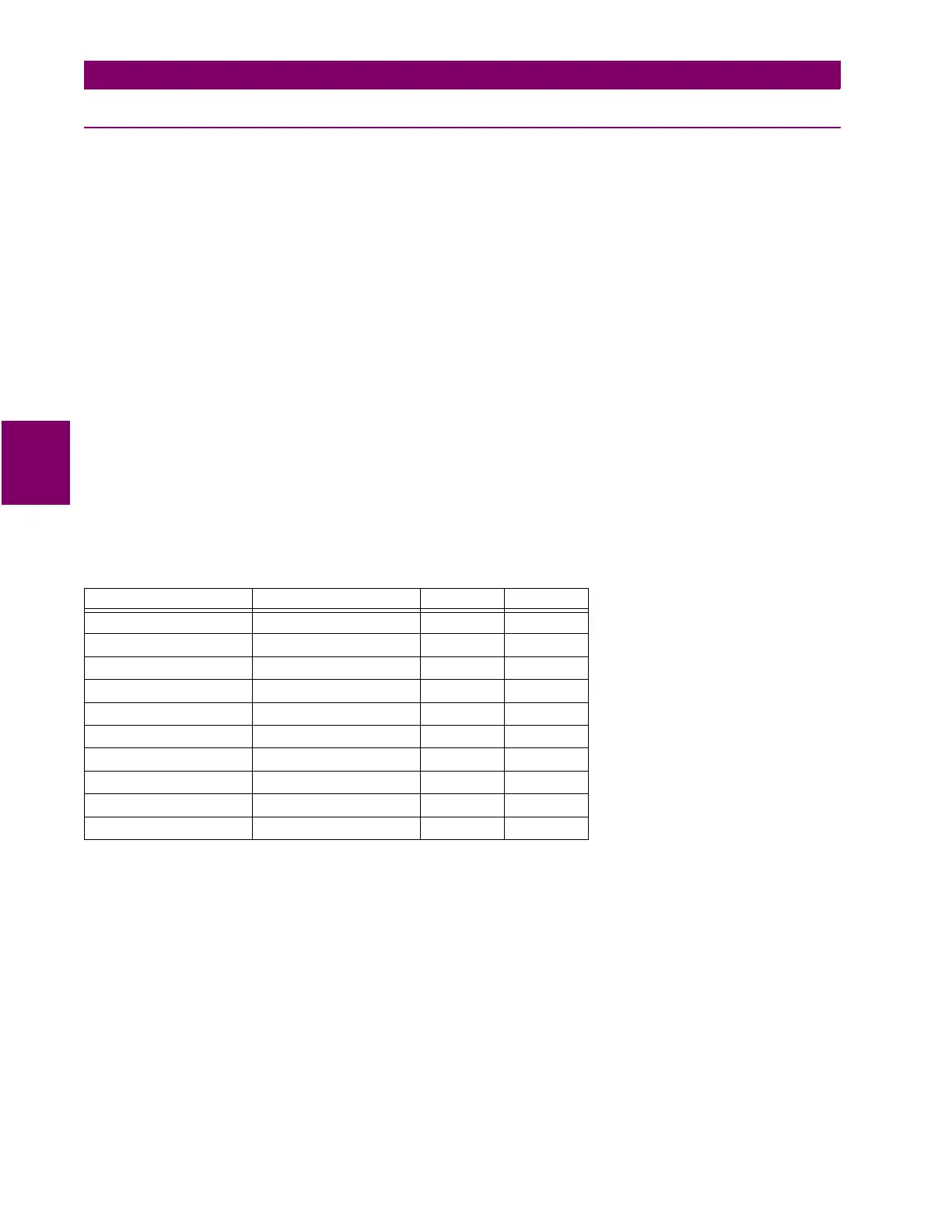

To perform a simulation on relay slave address 11H, the following simulated dial settings and input currents are required:

1. Set the communications TEST switch ON.

2. Load the dial settings and current values in setpoint memory using this function code

3. Issue the Function Code 5: EXECUTE OPERATION op code 02: REMOTE SETTINGS to select the dial settings from

memory just sent.

4. Issue the Function Code 5: EXECUTE OPERATION op code 04: SIMULATION ON to enable the relay to see the

phase and ground currents loaded into setpoint memory. The relay will begin timing out if an overcurrent condition

occurs.

5. Issue the Function Code 5: EXECUTE OPERATION op code 05: SIMULATION OFF to remove the simulated current.

The master transmission / slave response message format example for this function code is shown on the following page:

DIAL REQUIRED VALUE LOAD (H) ADDR (H)

phase pickup 60% of CT 0005 0060

phase curve shape normal inverse (LO) 0005 0061

phase time multiplier 7 0007 0062

phase instantaneous off 0001 0063

ground pickup 100% of CT 000A 0064

ground curve shape very inverse (HI) 0008 0065

ground time multiplier 3 0003 0066

ground instantaneous 0.8 x CT 0005 0067

phase current 120% of CT ???? 0068

ground current 50% of CT ???? 0069

Loading...

Loading...