Unit Size Terminal Torque Bolt size

41, 42, 43 and 44 Mains

Motor

19 Nm (168 in-lbs) M10

Load sharing

Brake

9.5 (84 in-lbs) M8

51 and 52 Mains

Motor

Load sharing

19 NM (168 in-lbs) M10

Brake 9.5 (84 in-lbs) M8

61, 62, 63 and 64 Mains

Motor

19 Nm (168 in-lbs) M10

Load sharing

Brake

Regen

19 Nm (168 in-lbs)

9.5 Nm (84 in-lbs)

19 Nm (168 in-lbs)

M10

M8

M10

Table 3.1: Torque for terminals

3.1.6 Shielded Cables

It is important that shielded and armoured cables are connected in a proper way to ensure high EMC immunity and low emissions.

Connection can be made using either cable glands or clamps:

• EMC cable glands: Generally available cable glands can be used to ensure an optimum EMC connection.

• EMC cable clamp: Clamps allowing easy connection are supplied with the frequency converter.

3.1.7 Motor cable

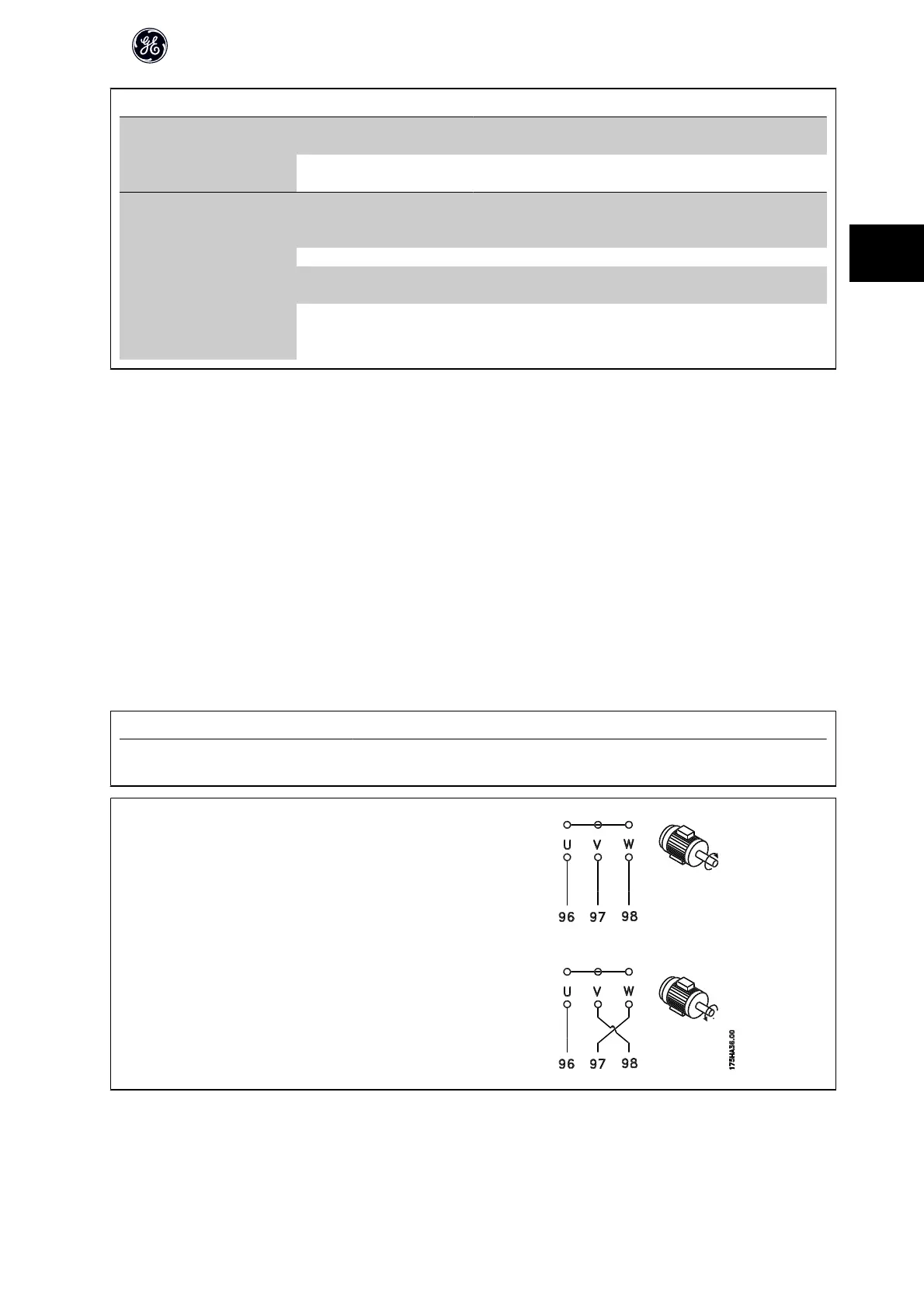

The motor must be connected to terminals U/T1/96, V/T2/97, W/T3/98. Earth to terminal 99. All types of three-phase asynchronous standard motors can be used

with a frequency converter unit. The factory setting is for clockwise rotation with the frequency converter output connected as follows:

Terminal No.

Function

96, 97, 98, 99 Mains U/T1, V/T2, W/T3

Earth

• Terminal U/T1/96 connected to U-phase

• Terminal V/T2/97 connected to V-phase

• Terminal W/T3/98 connected to W-phase

The direction of rotation can be changed by switching two phases in the motor cable or by changing the setting of par. H-08 Reverse Lock.

Motor rotation check can be performed using par. P-08 Motor Rotation Check and following the steps shown in the display.

AF-600 FP High Power Operating Instructions

21

3

Loading...

Loading...