5–86 489 GENERATOR MANAGEMENT RELAY – INSTRUCTION MANUAL

CHAPTER 5: SETPOINTS

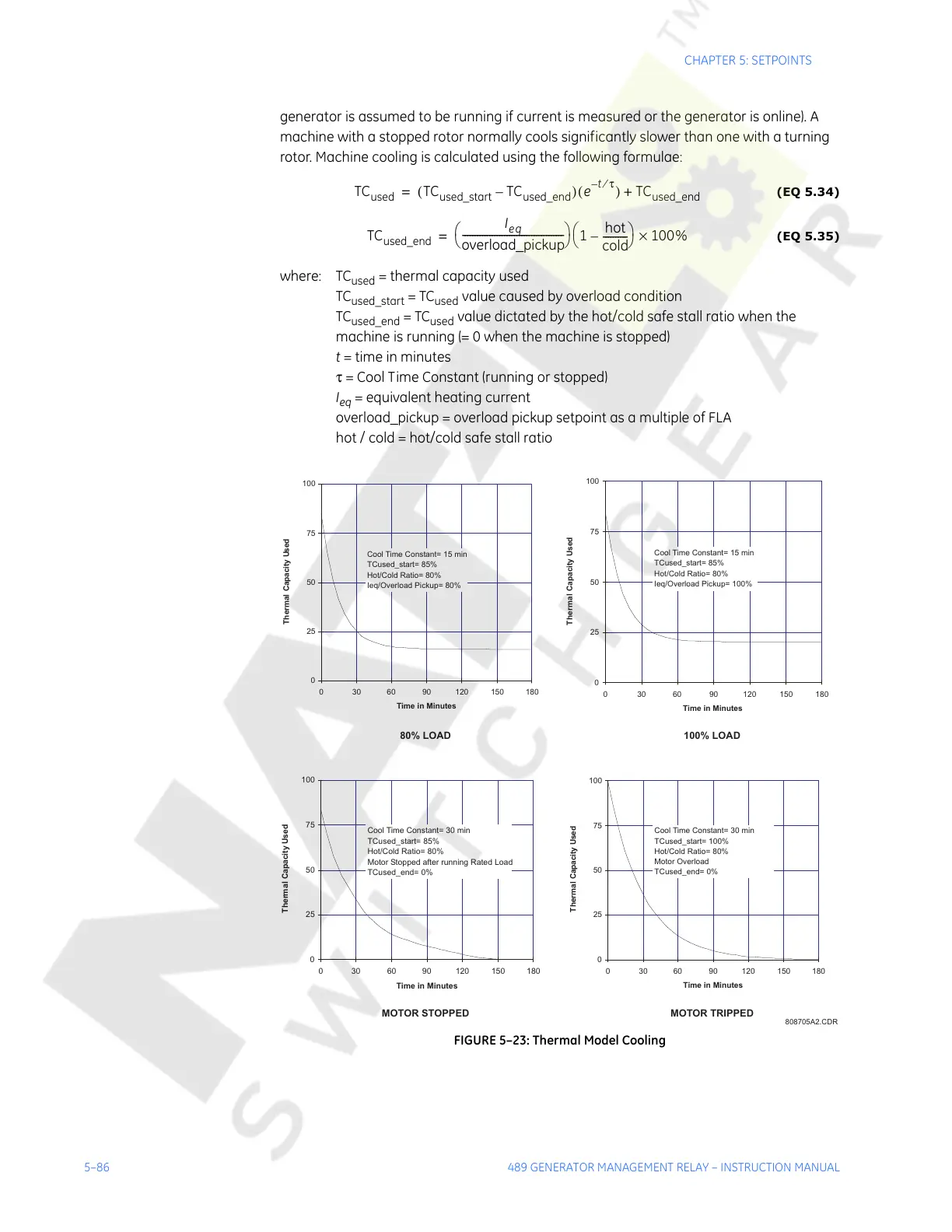

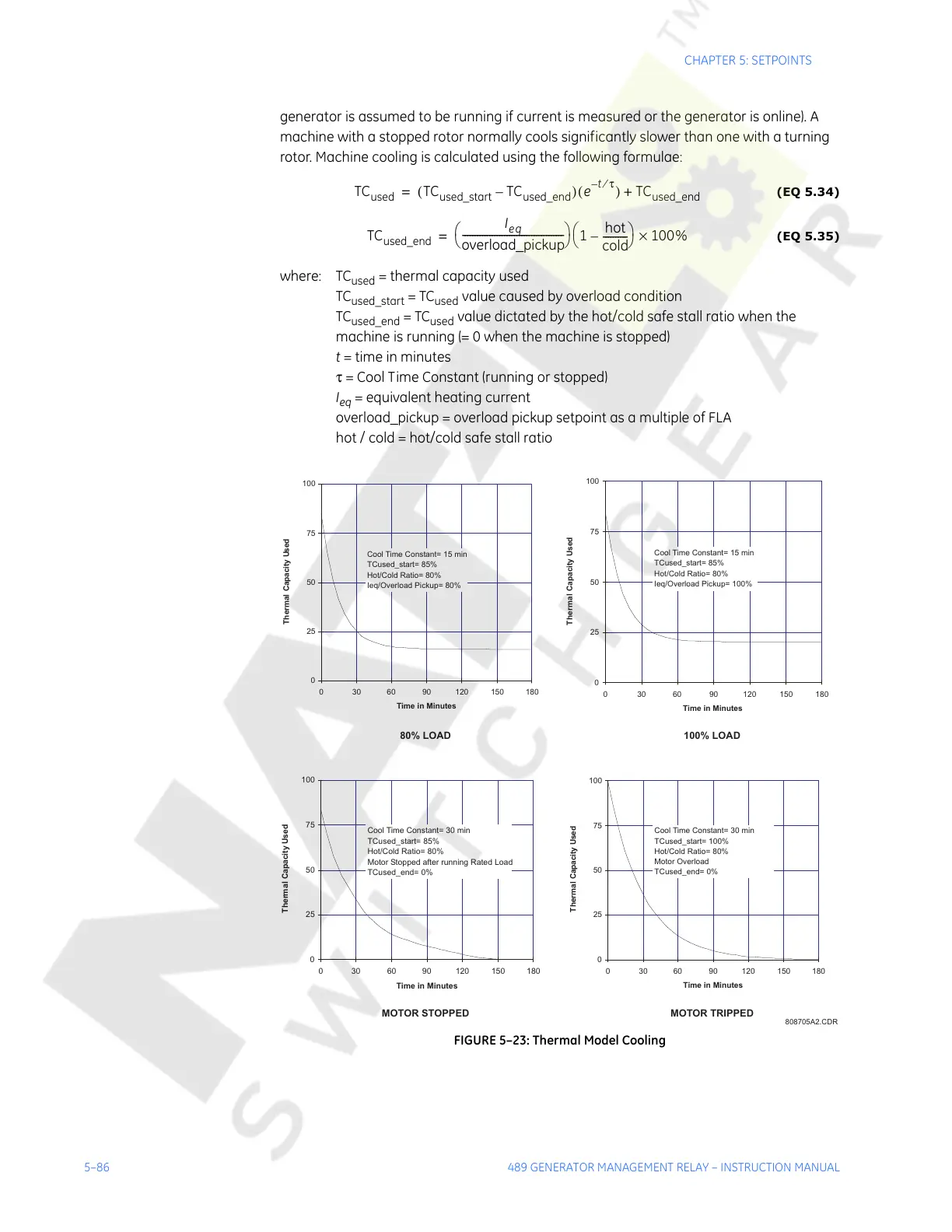

generator is assumed to be running if current is measured or the generator is online). A

machine with a stopped rotor normally cools significantly slower than one with a turning

rotor. Machine cooling is calculated using the following formulae:

(EQ 5.34)

(EQ 5.35)

where: TC

used

= thermal capacity used

TC

used_start

= TC

used

value caused by overload condition

TC

used_end

= TC

used

value dictated by the hot/cold safe stall ratio when the

machine is running (= 0 when the machine is stopped)

t = time in minutes

τ = Cool Time Constant (running or stopped)

I

eq

= equivalent heating current

overload_pickup = overload pickup setpoint as a multiple of FLA

hot / cold = hot/cold safe stall ratio

FIGURE 5–23: Thermal Model Cooling

TC

used

TC

used_start

TC

used_end

–()e

t τ⁄–

()TC

used_end

+=

TC

used_end

I

eq

overload_pickup

-----------------------------------------

⎝⎠

⎛⎞

1

hot

cold

----------–

⎝⎠

⎛⎞

100%×=

808705A2.CDR

0

25

50

75

100

0 30 60 90 120 150 180

Time in Minutes

Therm al Capacity Used

Cool Time Constant= 15 min

TCused_start= 85%

Hot/Cold Ratio= 80%

Ieq/Overload Pickup= 100%

0

25

50

75

100

0 30 60 90 120 150 180

Time in Minutes

Thermal Capacity Used

Cool Time Constant= 15 min

TCused_start= 85%

Hot/Cold Ratio= 80%

Ieq/Overload Pickup= 80%

0

25

50

75

100

0 30 60 90 120 150 180

Time in Minutes

Thermal Capacity Used

Cool Time Constant= 30 min

TCused_start= 85%

Hot/Cold Ratio= 80%

Motor Stopped after running Rated Load

TCused_end= 0%

0

25

50

75

100

0 30 60 90 120 150 180

Time in Minutes

Thermal Capacity Used

Cool Time Constant= 30 min

TCused_start= 100%

Hot/Cold Ratio= 80%

Motor Overload

TCused_end= 0%

MOTOR TRIPPED

100% LOAD

MOTOR STOPPED

80% LOAD

Courtesy of NationalSwitchgear.com

Loading...

Loading...