2–4 489 GENERATOR MANAGEMENT RELAY – INSTRUCTION MANUAL

CHAPTER 2: INTRODUCTION

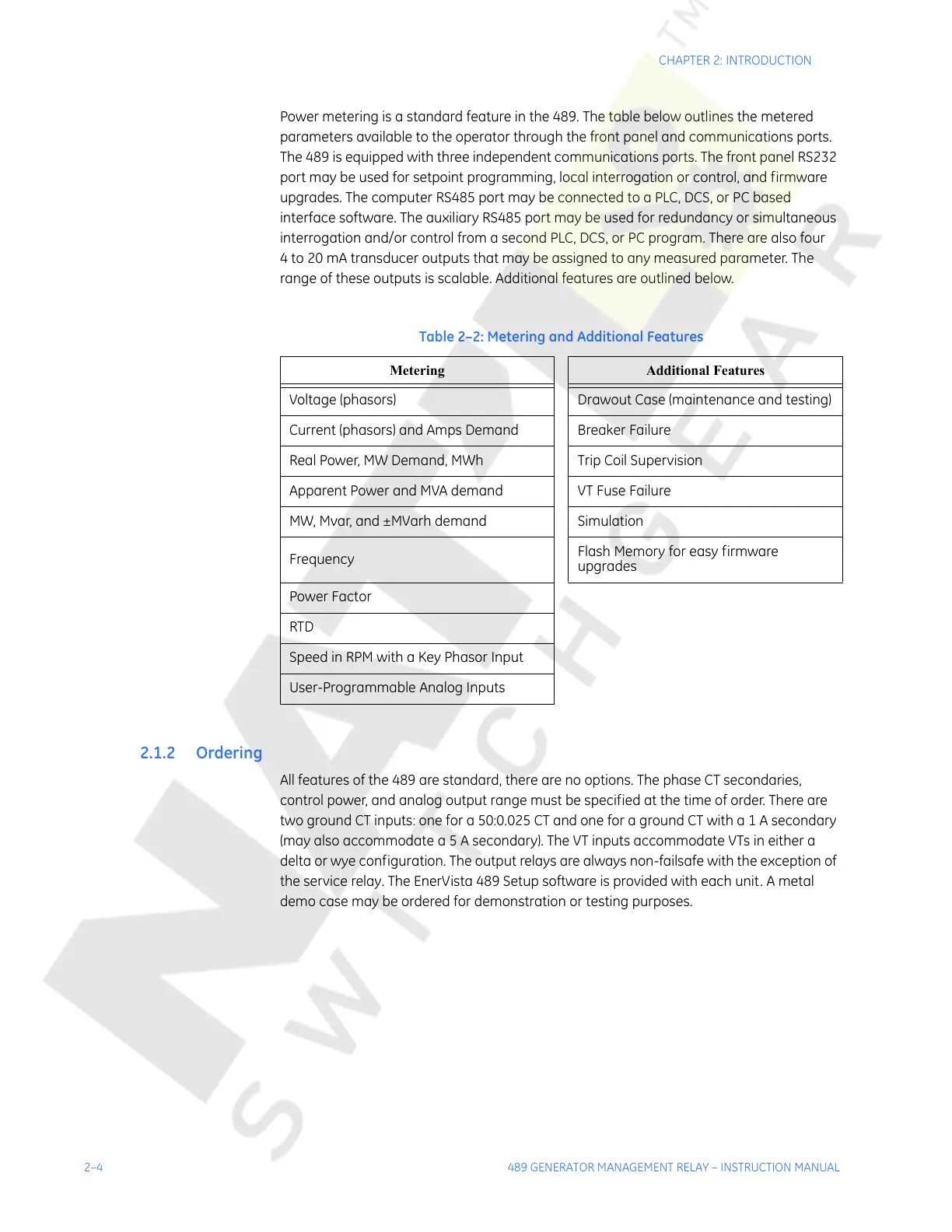

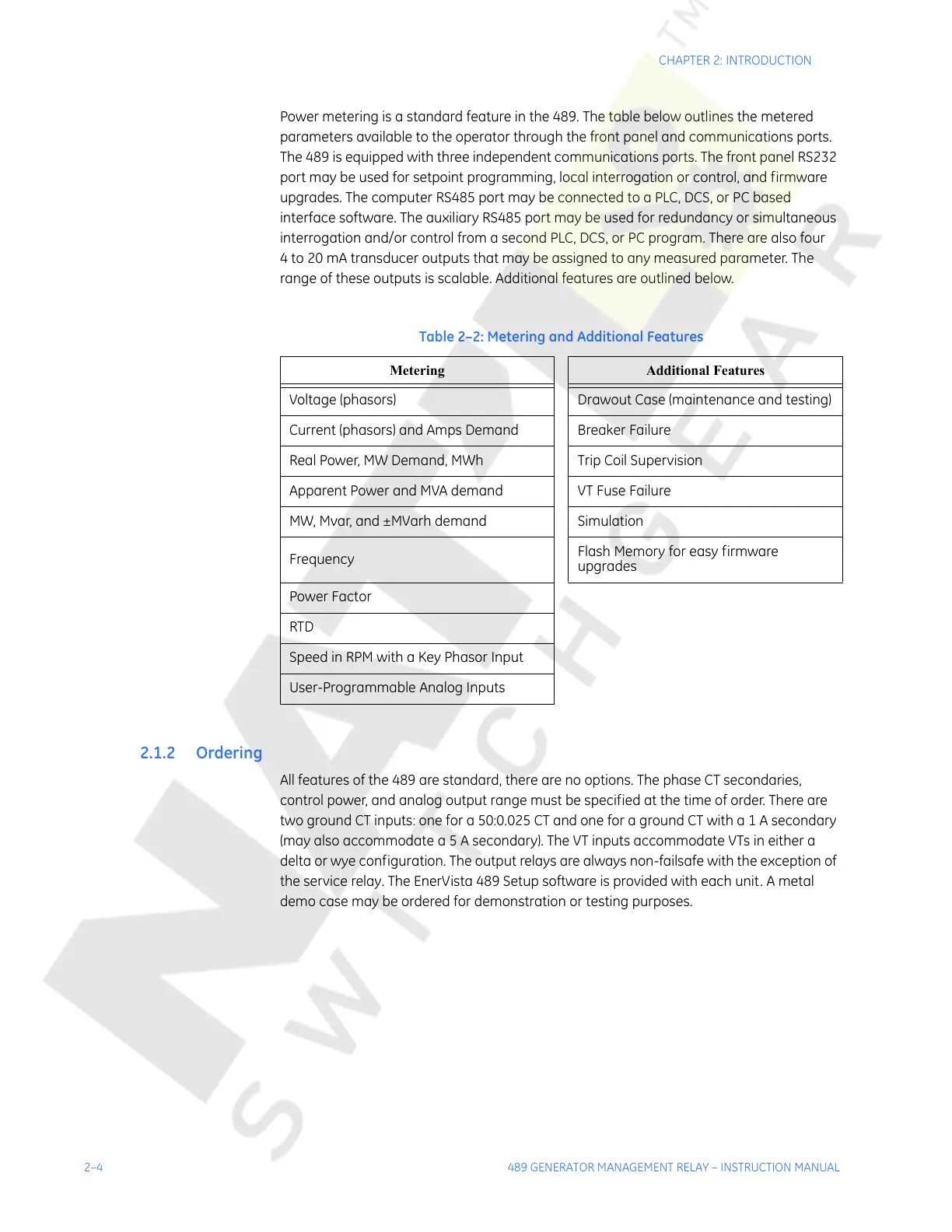

Power metering is a standard feature in the 489. The table below outlines the metered

parameters available to the operator through the front panel and communications ports.

The 489 is equipped with three independent communications ports. The front panel RS232

port may be used for setpoint programming, local interrogation or control, and firmware

upgrades. The computer RS485 port may be connected to a PLC, DCS, or PC based

interface software. The auxiliary RS485 port may be used for redundancy or simultaneous

interrogation and/or control from a second PLC, DCS, or PC program. There are also four

4 to 20 mA transducer outputs that may be assigned to any measured parameter. The

range of these outputs is scalable. Additional features are outlined below.

2.1.2 Ordering

All features of the 489 are standard, there are no options. The phase CT secondaries,

control power, and analog output range must be specified at the time of order. There are

two ground CT inputs: one for a 50:0.025 CT and one for a ground CT with a 1 A secondary

(may also accommodate a 5 A secondary). The VT inputs accommodate VTs in either a

delta or wye configuration. The output relays are always non-failsafe with the exception of

the service relay. The EnerVista 489 Setup software is provided with each unit. A metal

demo case may be ordered for demonstration or testing purposes.

Table 2–2: Metering and Additional Features

Metering Additional Features

Voltage (phasors) Drawout Case (maintenance and testing)

Current (phasors) and Amps Demand Breaker Failure

Real Power, MW Demand, MWh Trip Coil Supervision

Apparent Power and MVA demand VT Fuse Failure

MW, Mvar, and ±MVarh demand Simulation

Frequency

Flash Memory for easy firmware

upgrades

Power Factor

RTD

Speed in RPM with a Key Phasor Input

User-Programmable Analog Inputs

Courtesy of NationalSwitchgear.com

Loading...

Loading...