Receipt, storage and transport 16

Code No. 549758

Rev. nº 10/0418

2.3. Transport

CAUTION!

IT IS COMPULSORY FOR ALL MANOEUVRING TO BE CARRIED OUT BY STAFF SPECIALISING IN SUCH

TRANSPORTING.

ALL HOISTING OR TRANSPORT TOOLS AND DEVICES MENTIONED IN THIS SECTION MUST BE

AUTHORISED FOR LOADS HIGHER THAN THE MACHINE GROSS WEIGHTS, AND SUITABLE FOR THE

MACHINE SIZES (Refer to Section 2.4).

VERY IMPORTANT!

DO NOT OVERLOAD THE SLINGS. THE ANGLE FORMED BETWEEN THEM MUST ALWAYS BE LESS

THAN 60°. USE SLINGS OF SUFFICIENT LENGTH. (Fig. 2.2). DO NOT USE SLINGS TO LOAD MODELS

ED900 AND ED1250.

ALWAYS TRANSPORT THE MACHINE IN AN UPRIGHT POSITION.

DO NOT USE ROLLERS TO MOVE THE MACHINE.

TO MOVE THE MACHINE ACROSS THE FLOOR, USE A FORK-LIFT TRUCK.

THE FRONT IS DISTINGUISHED BY THE LABEL INDICATING FRONT/FRENTE/AVANT.

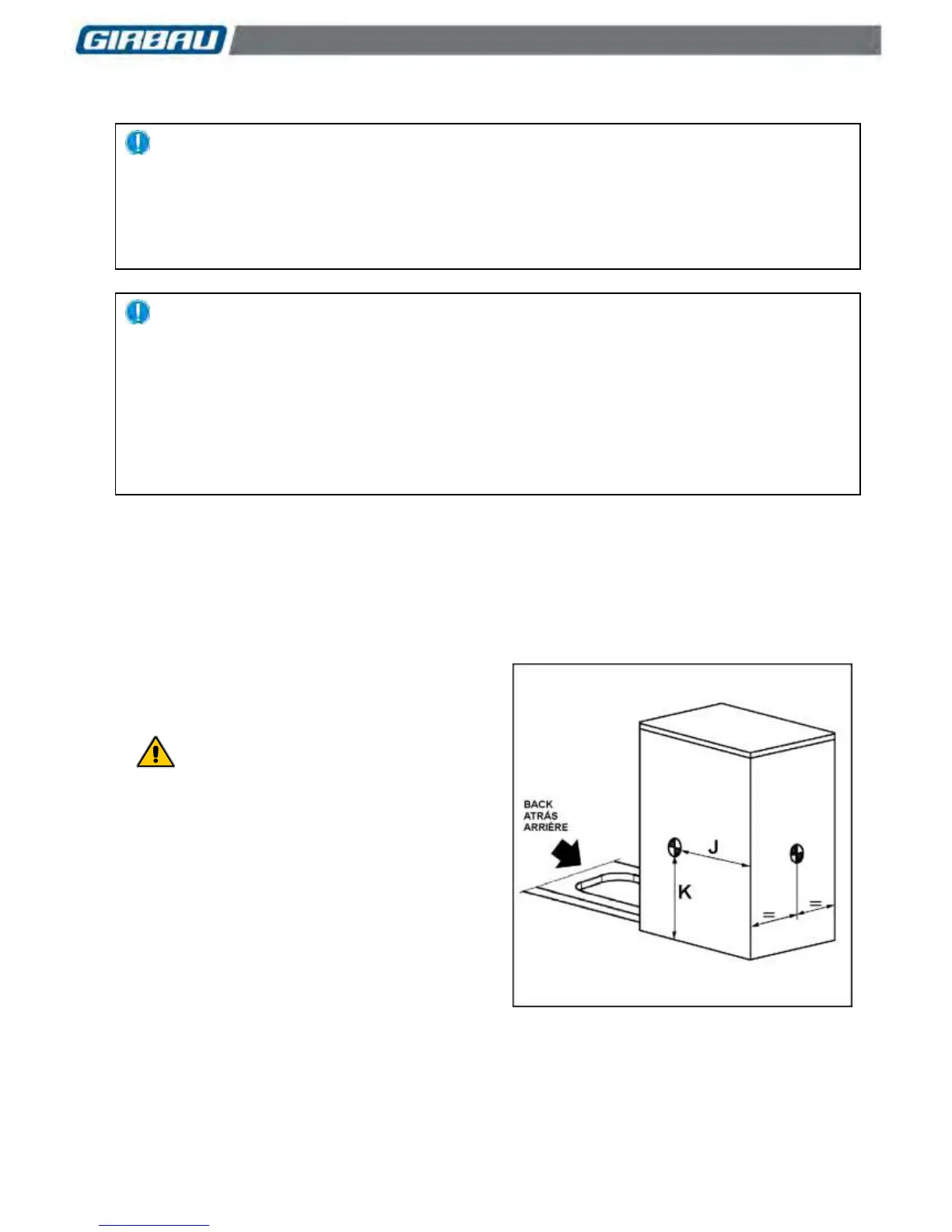

THE REAR IS DISTINGUISHED BY THE LABEL INDICATING BACK/ATRÁS/ARRIÈRE.

2.3.1. Transporting with packaging. Fork-lift truck

Before moving the machine, make sure the items to be used are suitable and capable of bearing its weight.

See weights and measures in the table in Section 2.4.

Move the machine with the crate, using a fork-lift truck.

On models ED260, ED340, ED460 and ED660,

the machine’s centre of gravity is displaced towards the

rear, and for this reason, the blades of forklift trucks

should always be inserted from the rear (Fig. 2.5). Do

not lift the machine by inserting the blades of the forklift

truck from the front or from the sides.

On models ED900 and ED1250 the blades of forklift

trucks should be inserted from the rear or from the

sides. Do not lift the machine by inserting the blades of

the forklift truck from the front.

Loading...

Loading...