Repair

34 3A9286B

Reassemble the Standard Diaphragms

1. Assemble the diaphragm backers (14, if applicable),

diaphragms (13), fluid side plates (11), and seals

(16, if applicable) with the fasteners (15) exactly as

shown for your equipment model. See your related

parts manual. See Related Manuals, page 2.

NOTE: Face the rounded side of the fluid side plate

(11) toward the diaphragm (13).

NOTE: Apply thread locker to the fastener (15) for

all diaphragm assemblies.

FIG. 15: Reassemble Standard Diaphragms (Hygienic

Model Shown)

2. Install the assembled diaphragm assemblies into

the shaft with plate (1b) and hand-tighten the

fasteners (15).

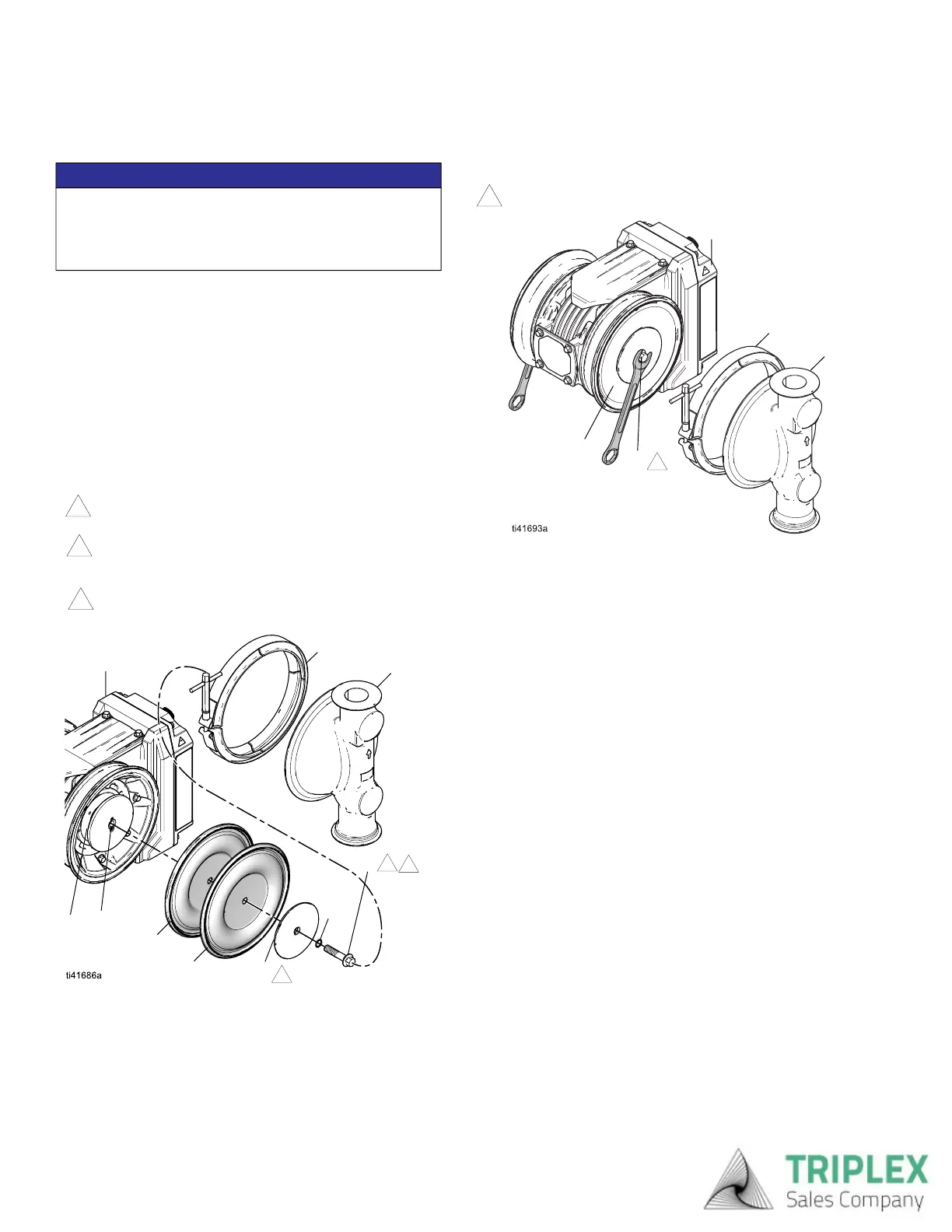

3. Use an applicable wrench to firmly hold one

fastener (15) in place. At the same time, use an

applicable wrench to torque the opposite fastener

(15) to 50 ft-lb (68 N•m). See F

IG. 16.

FIG. 16: Tighten Standard Diaphragms

4. Align the fluid covers (3) to the motor (1).

5. Install clamps (6a) to hold the fluid covers (3) in

place.

NOTE: To ensure proper spacing and alignment of

the manifolds, install clamps (6a) loose enough to

allow for fluid cover movement before securing the

fluid covers in place.

6. Reassemble the check valves and manifolds as

explained in Reassemble Check Valves, page 32.

NOTICE

After reassembly, allow the thread locker to cure for

12 hours, or per instructions of the manufacturer,

prior to operating the equipment. The equipment will

be damaged if the diaphragm shaft fastener loosens.

Apply a high-strength thread locker to attach the

fastener to the diaphragm plate.

Apply a medium-strength thread locker to the shaft

side of the fastener to attach the diaphragm to the

shaft.

Rounded side faces toward the diaphragm (13).

3

16

13

14

1

1a

1

2

15

3

11

1b

6a

Torque to 50 ft-lb (68 N•m).

3

1

15

13

6a

Triplex Sales

1-847-839-8442

www.triplexsales.com

Loading...

Loading...