Designing a system20

Date of issue: October 2011

Automatic Greasing System OnePlus

EG1605R01

3Designing a system

3.1 Introduction

The following aspects influence the design of a OnePlus greasing system:

1. The number of grease points to be connected and:

• The position of the grease points on the vehicle or machine.

• The grease demand of the grease points.

• The greasing interval required by the grease points.

2. The space available on the vehicle or machine for the pump unit and the dis-

tribution blocks.

3. The NLGI class of the grease to be used and the lowest ambient temperature

under which the greasing system is expected to function.

3.2 Points of departure

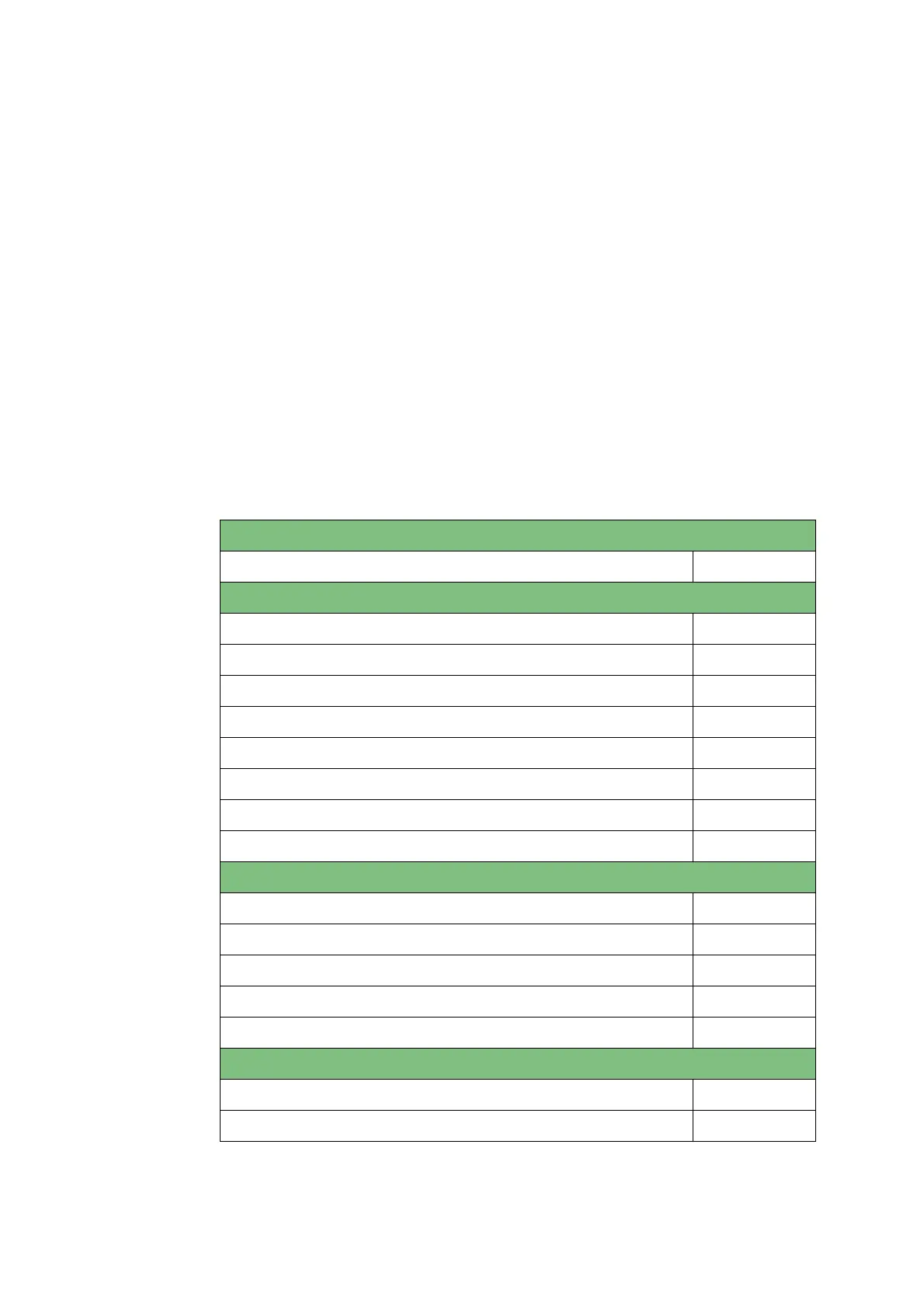

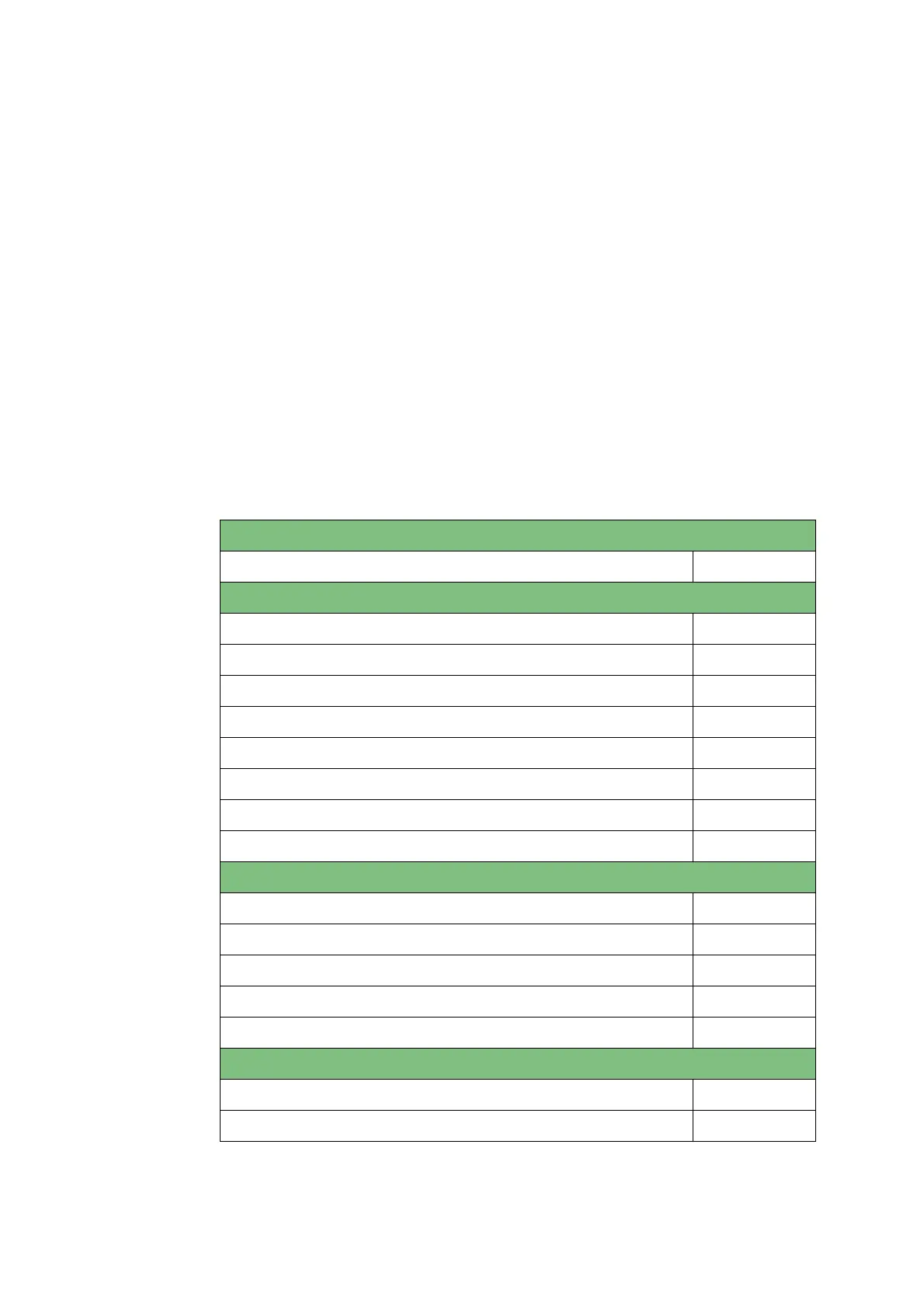

Pump

Maximum working pressure 275 bar

Distribution blocks

Maximum number of distribution blocks in series 2

Available segment types table 1

Minimum number of doser segments in a distribution block 3

Maximum number of doser segments in a distribution block 12

Pressure drops in a distribution block, related to: table 2

• The number of segments in the distribution block

• The NLGI class of the grease used

• The ambient operating temperatures

Primary and secondary grease lines

Pressure drops in the grease lines, connected with: table 3

• The diameter of the lines

• The length of the lines

• The NLGI class of the grease used

• The ambient operating temperatures

Resistance at the grease point

Ball or roller bearing 5 bar

Slide bearing 15 bar

Loading...

Loading...