Automatic Greasing System OnePlus

Maintenance

37

Date of issue: October 2011

EG1605R01

5.3 Filling the grease reservoir

When the grease in the reservoir reaches the minimum level indicated on the res-

ervoir, the reservoir needs to be refilled. To facilitate this, the pump unit is fitted

with a grease nipple onto which a garage grease pump can be placed.

To be able to fill the reservoir using a special filling pump, a special filler coupling

can be installed.

Groeneveld

can supply you with both mobile or stationary, hand-

operated or pneumatic filling pumps.

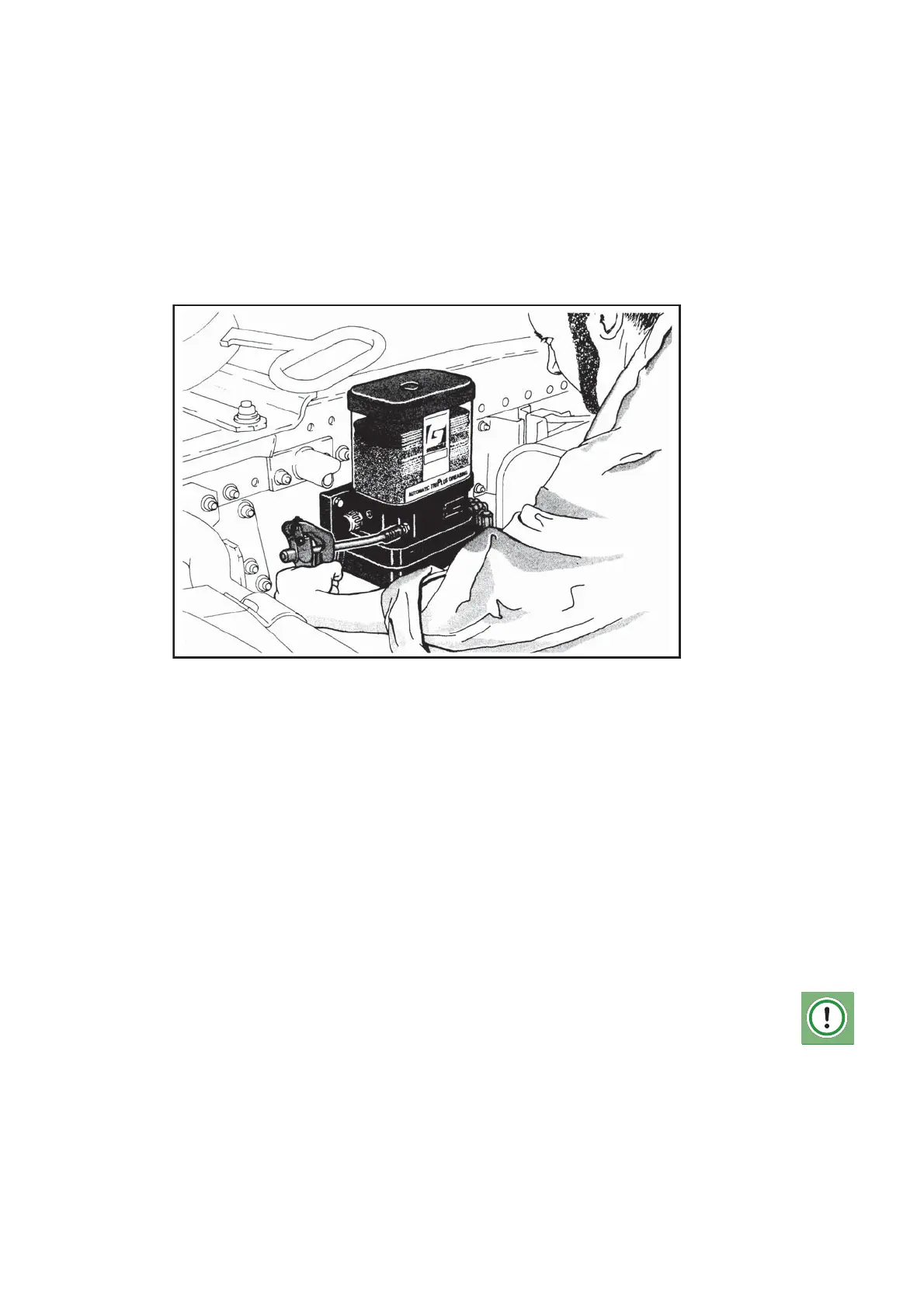

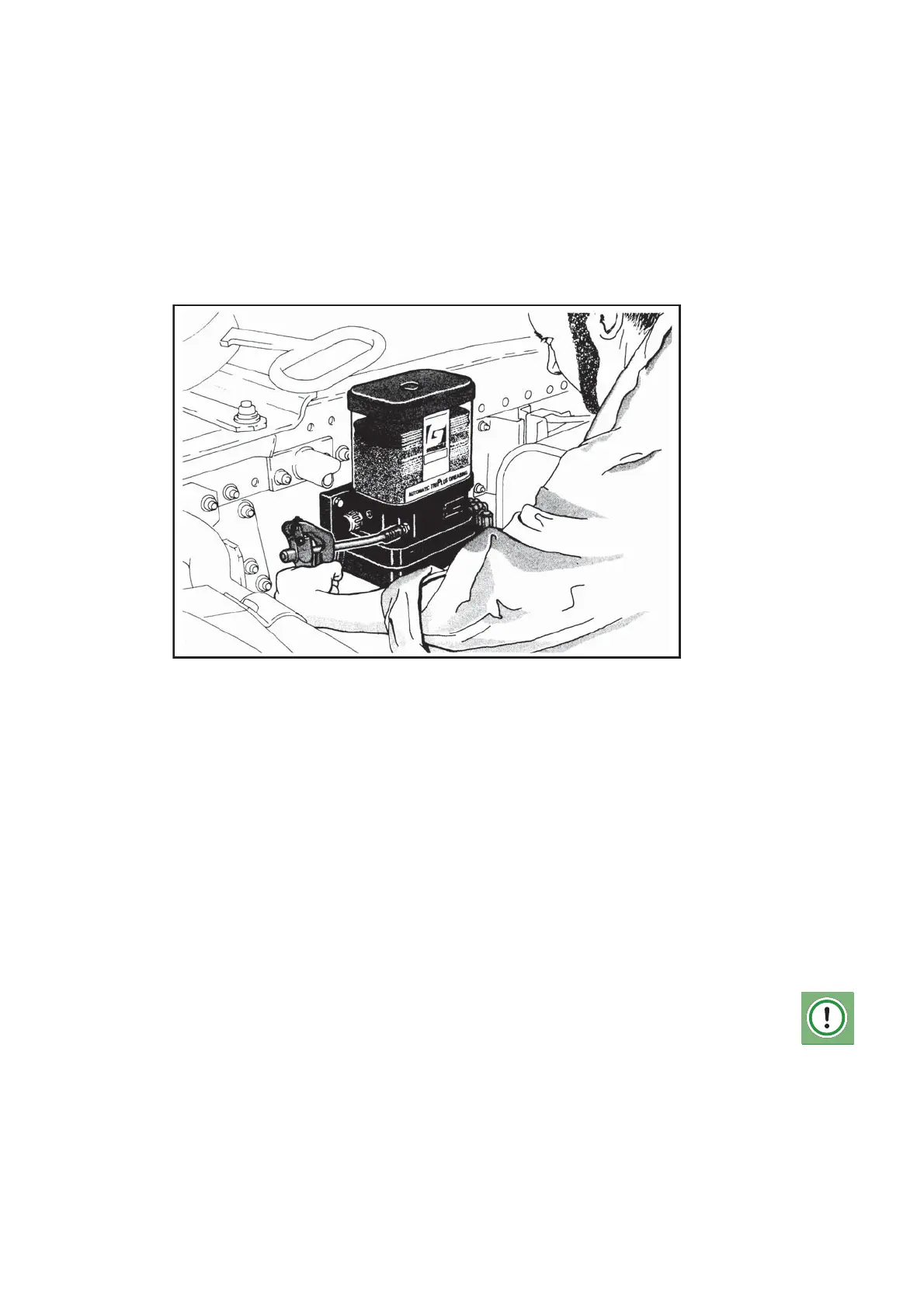

Figure 5.1 Filling the reservoir with a garage grease pump.

Filling procedure

The grease pump must be suitable for class 2 grease.

First fill the filling hose with grease (if the filling pump or grease barrel is new). This

prevents air being introduced in the grease reservoir.

1. Remove the dust cap of the filler coupling.

2. Clean the filler coupling and the coupling on the hose thoroughly.

3. Lock the hose onto the filler coupling or position the grease gun onto the

filler coupling.

4. Fill the reservoir up to its maximum level, as indicated on the reservoir. Never

fill the reservoir any higher than the maximum level indicated, otherwise the

follower piston may become damaged.

5. Remove the filling hose or grease gun.

6. Clean the dust cap and the grease nipple or filling coupling with a clean rag.

Place the dust cap back onto the filler coupling.

ATTENTION

Check the grease filter behind the filler coupling every 500 hours and clean

or renew the filter.

Air pockets that entered the grease reservoir during filling can escape the

reservoir through an opening in the top of the guide rod when the follower

piston is just above maximum level. These air pockets, together with excess

grease, will exit via the de-aerating opening at the left side of the pump

unit.

Loading...

Loading...