21

English (US)

6.7.6 Wiring checks and installation

Before making the final surface wiring

connection of the submersible drop cable to the

control box or control panel, it is a good practice

to check the insulation resistance to ensure that

the cable and splice are good. Measurements

for a new installation must be at least 200

megaohms. See the table in section

6.7.7 Insulation resistance and ohm value chart.

If the insulation resistance of the cable and

splice is measured at higher than 200

megaohms, run the submersible drop cable

through the well seal by means of a conduit

connector to prevent foreign matter from

entering the well casing.

Always protect the submersible drop cable with

conduit from the pump to the control box or

control panel. See fig. 16.

Finish the wiring and verify that all electrical

connections are made in accordance with the

wiring diagram.

Check to ensure that the control box or control

panel and high-voltage surge arrester have been

grounded.

Route conductors properly such as in conduit

where called for by Local Code to protect the

conductors.

6.7.7 Insulation resistance and ohm value

chart

Insulation resistance in a submersible pumping

system is a measure of the ability of the motors

and/or cables to withstand normal voltage and

transient voltage without breakdown and failure.

An "adequate" level of insulation resistance is

not a constant value, but depends on the

installation voltage and conditions, and whether

the measured resistance is lowered by a specific

weak point or by widely distributed conductance

such as in cable insulation material itself. For

this reason, values for acceptable resistance

cannot be specific.

Insulation resistance measurements

Measure insulation resistance at the time of

initial motor installation and periodically

thereafter. In deep set submersible installations,

take measurements throughout the installation

process to detect potential cable insulation or

connection damage before the unit is completely

installed. The insulation resistance table in this

section describes the condition of the insulation

system for a submersible motor system of 600 V

or less, based on megohmmeter readings.

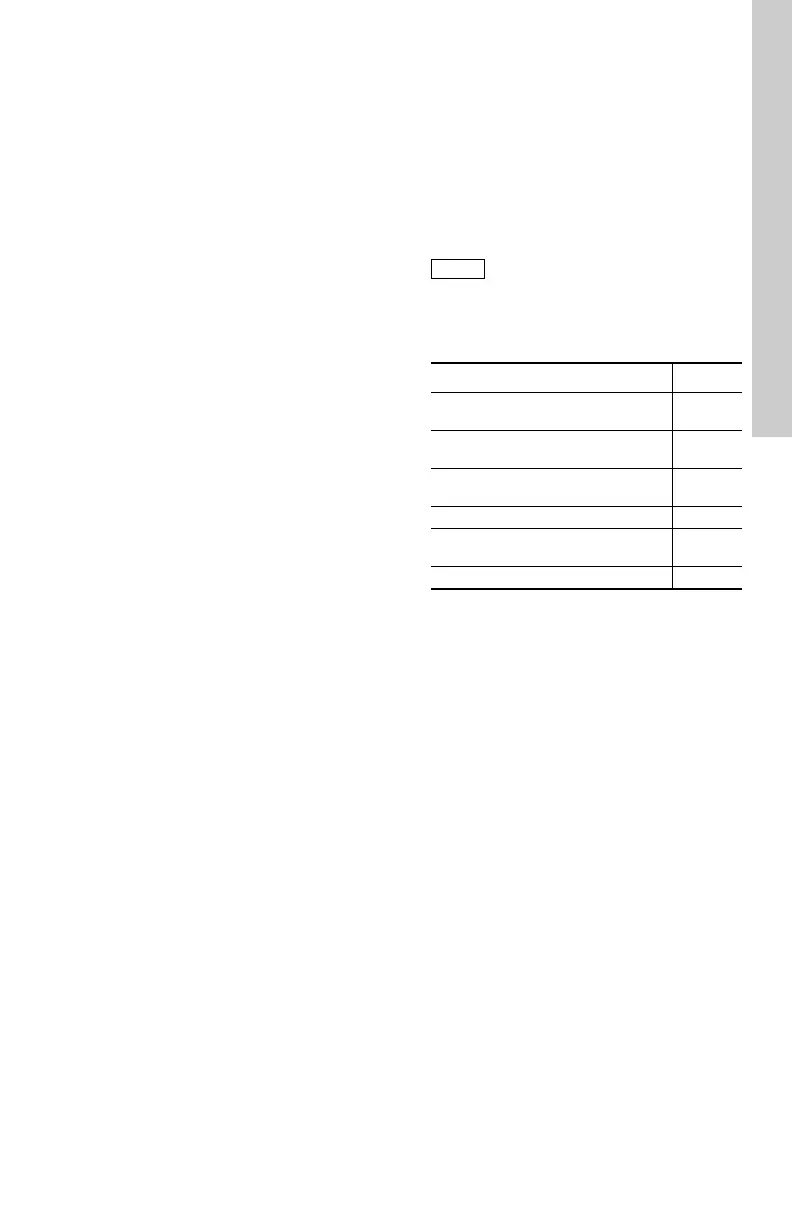

The table below shows suggested values of

insulation resistance and the test voltage in

relation to the rated voltage of the motor.

If the rated motor voltage is less than or equal to

500 V, the insulation resistance must be

measured at a test voltage of 500 VDC.

If the rated motor voltage is greater than 500 V,

the insulation resistance must be measured at a

test voltage of 1000 VDC.

Measure the insulation resistance in

accordance with local codes and

regulations.

Rated voltage ≤ 500 [V] > 500 [V]

Condition of motor and

cable

[MΩ][MΩ]

New motor without

submersible drop cable

≥ 200 ≥ 200

Used motor which can be

re-installed in well

≥ 10 ≥ 10

New motor in well ≥ 20 ≥ 20

Motor in good condition

in well

≥ 0.5 ≥ 1

Damaged insulation < 0.5 < 1

Loading...

Loading...