5. Operation

52 PNEG-1156ETL Design III Series Grain Stir-Ator CSA

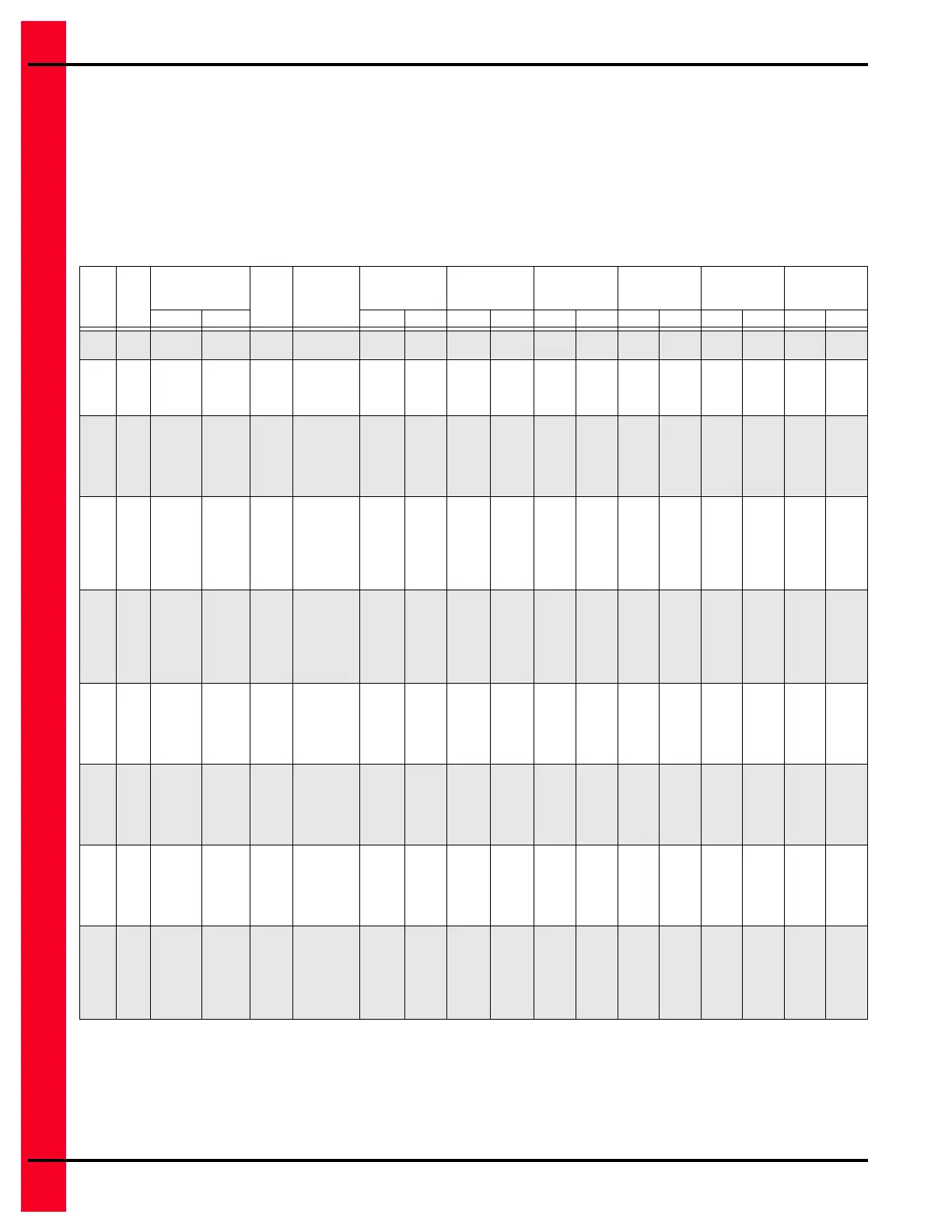

**Number of Stir-Ator Augers Versus Fan and Heater Sizes

The

below

and

on Page 53

charts are based on ambient air temperature of 50°F, 60% relative humidity,

16' (4.9 m) of corn and 7%-12% moisture removal (23.5%-16% final moisture). This chart is designed as a

guide only. Fan performance will vary considerably from one manufacturer to another and other factors can

change the approximate bushels per day. Choose from Stir-Ator models with two (2) or three (3) augers to

fit bins from 18' (3.5 m) to 48' (14.6 m). Each model gives you all the exclusive Stir-Ator features that can

turn a simple bin into a wet-holding tank, dryer and storage bin - all in one unit.

Heated Air (Heat Rise above Ambient Temperature-Fahrenheit) - Corn-16'

* All multiple fans are in parallel. Multiply drying rates x 0.77 for 10 point removal.

Multiply drying rates x 1.35 for 5 point removal.

All multiple fan static pressures (where multipliers are shown) fall within acceptable performance guidelines.

** Stir-Ator down auger recommendations, as shown in the chart, are for stir-dry bins only. For grain flow continuous flow drying

system application, please refer to grain flow drying chart for down auger recommendations.

Bin

Size

Fan

HP

Drying Rate

Multipliers * for

More Fans

CFM

for

1 Fan

Static

Pressure

for 1 Fan

25° 50° 75° 100° 125° 150°

2 Fans 3 Fans BPD # Aug BPD # Aug BPD # Aug BPD # Aug BPD # Aug BPD # Aug

18'

5.0

7.5

1.2

1.2

NA

NA

6600

7100

3.5

3.9

360

490

2

2

750

810

2

2

1100

1180

2

2

1480

1590

2

2

1850

1990

3

3

2240

2400

3

3

21'

5.0

7.5

10.0

12.5

1.2

1.2

1.2

1.2

NA

NA

NA

NA

8100

9100

9200

10600

3.0

3.6

3.6

4.5

450

500

510

580

2

2

2

2

920

1030

1040

1200

2

2

2

2

1350

1520

1530

1770

2

2

2

3

1810

2030

2060

2370

3

3

3

3

2270

2560

2580

2980

3

3

3

3

2740

3080

3120

3590

3

3

3

3

24'

7.5

10.0

10 C

12.5

15 C

20 C

1.3

1.2

1.5

1.3

1.4

NA

NA

NA

NA

NA

NA

NA

10200

11000

11300

12000

13100

15500

2.8

3.2

3.3

3.6

4.1

5.3

560

610

620

660

720

850

2

2

2

2

2

2

1160

1250

1280

1360

1490

1760

2

2

2

2

2

3

1700

1830

1880

2000

2180

2580

3

3

3

3

3

3

2280

2460

2530

2680

2930

3460

3

3

3

3

4

4

2860

3090

3170

3370

3680

4350

4

4

4

4

4

4

3460

3730

3830

4070

4440

5250

4

4

4

4

4

4

27'

7.5

10 C

10.0

12.5

15 C

20 C

30 C

1.4

1.6

1.3

1.4

1.5

1.5

1.3

NA

NA

NA

NA

NA

NA

NA

10900

12000

12200

13100

14100

16600

19200

2.2

2.5

2.6

2.9

3.2

4.2

5.2

600

660

670

720

780

910

1060

2

2

2

2

2

2

2

1240

1360

1380

1490

1600

1880

2180

2

2

2

2

2

3

3

1820

2000

2030

2180

2350

2770

3200

3

3

3

3

3

3

4

2440

2680

2730

2930

3150

3720

4290

3

3

3

4

4

4

4

3060

3370

3430

3680

3960

4660

5390

4

4

4

4

4

4

4

3690

4070

4130

4440

4780

4620

6500

4

4

4

4

4

4

4

30'

7.5

10 C

10.0

12.5

15 C

20 C

30 C

1.6

1.7

1.5

1.5

1.6

1.6

1.6

NA

NA

NA

NA

NA

NA

NA

11400

12500

12900

13900

14900

17600

20300

1.7

2.0

2.1

2.3

2.6

3.3

4.1

630

690

710

760

820

970

1120

2

2

2

2

2

2

2

1290

1420

1460

1580

1690

2000

2300

2

2

2

2

3

3

3

1900

2080

2150

2320

2480

2940

3390

3

3

3

3

3

4

4

2550

2790

2880

3110

3330

3930

4540

3

4

4

4

4

4

4

3200

3510

3620

3900

4180

4940

5700

4

4

4

4

4

4

4

3680

4230

4370

4710

5050

5960

6880

4

4

4

4

4

4

4

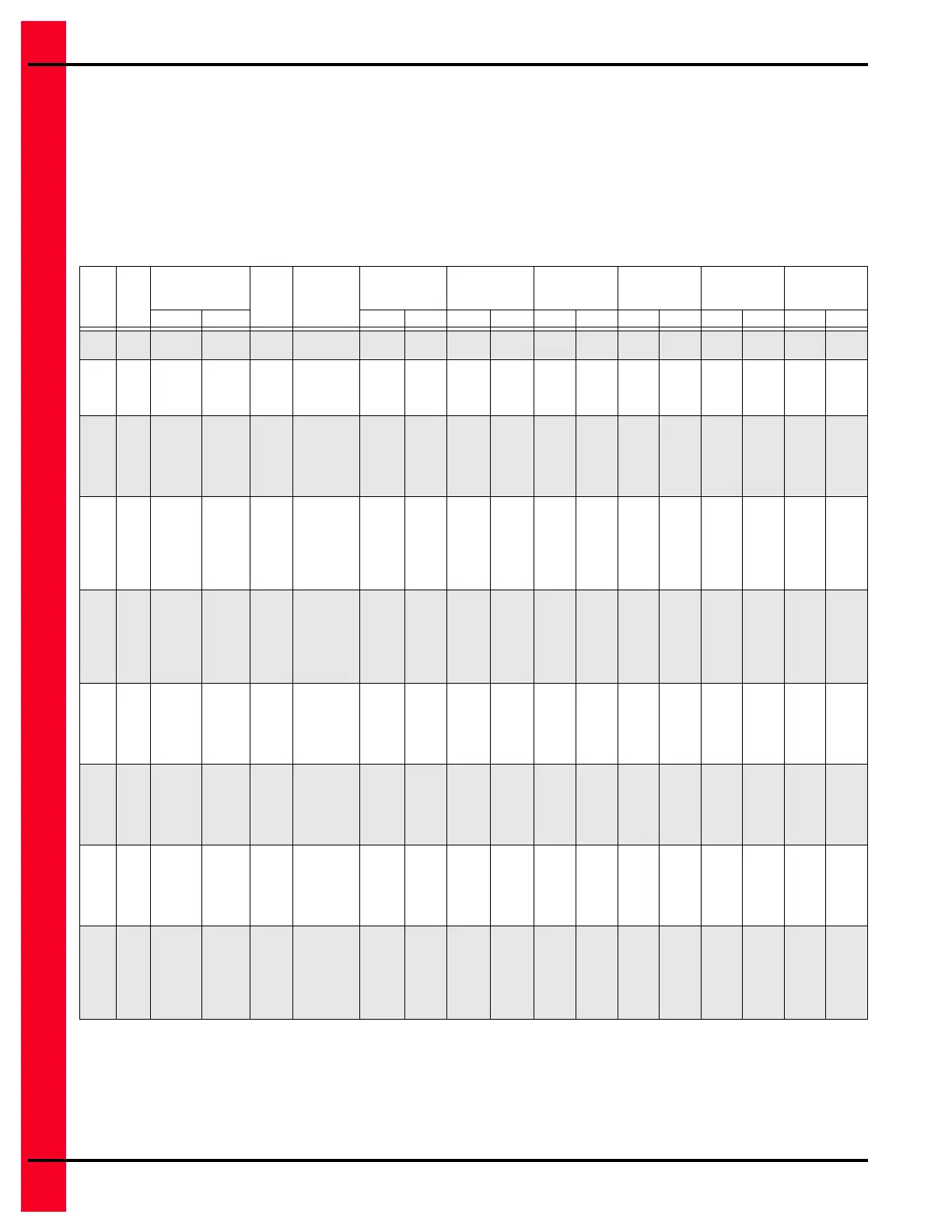

33'

10 C

10.0

12.5

15 C

20 C

30 C

1.7

1.6

1.6

1.6

1.6

1.6

NA

NA

NA

NA

NA

NA

12800

13200

14600

15400

18400

21200

1.6

1.6

1.9

2.0

2.6

3.3

700

730

800

850

1010

1170

2

2

2

2

2

2

1450

1500

1660

1750

2090

2400

2

2

2

3

3

3

2130

2200

2430

2570

3070

3530

3

3

3

3

4

4

2860

2950

3260

3440

4110

4740

4

4

4

4

4

4

3590

3710

4100

4330

5170

5950

4

4

4

4

4

4

4340

4470

4950

5220

6230

7180

4

4

4

4

4

4

36'

10 C

10.0

12.5

15 C

20 C

30 C

1.8

1.7

1.7

1.7

1.7

1.7

NA

NA

NA

NA

NA

NA

13100

13500

15000

15800

18900

21800

1.3

1.3

1.5

1.6

2.1

2.6

720

740

830

870

1040

1200

2

2

2

2

2

2

1490

1530

1700

1790

2140

2470

2

2

3

3

3

3

2180

2250

2500

2630

3150

3630

3

3

3

4

6

6

2930

3020

3350

3530

4220

4870

4

4

6

6

6

6

3680

3790

4210

4440

5310

6120

6

6

6

6

6

6

4440

4570

5080

5350

6400

7390

6

6

6

6

6

6

42'

10.0

12.5

15.0

20 C

30 C

40 C

1.8

1.8

1.8

1.8

1.8

1.8

2.4

2.3

2.4

2.4

2.4

2.4

13800

15600

16400

19500

22600

26400

0.9

1.1

1.1

1.4

1.8

2.2

760

860

900

1070

1240

1450

2

2

2

2

2

3

1560

1770

1860

2210

2560

2990

2

3

3

3

3

6

2300

2600

2730

3250

3770

4400

3

3

6

6

6

6

3080

3490

3670

4360

5050

5900

6

6

6

6

6

6

3880

4380

4610

5480

6350

7410

6

6

6

6

6

6

4680

5290

5560

6610

7660

8940

6

6

6

6

6

6

48'

10.0

12.5

15 C

20 C

30 C

40 C

50 C

1.9

1.8

1.9

1.9

1.8

1.9

1.8

2.7

2.5

2.6

2.6

2.5

2.6

2.4

13900

16000

16700

19900

23100

26800

31600

0.6

0.8

0.8

1.0

1.2

1.5

1.9

760

880

920

1100

1270

1470

1740

2

2

2

2

3

3

3

1580

1810

1890

2260

2620

3040

3580

2

3

3

3

6

6

6

2320

2670

2790

3320

3850

4470

5270

3

6

6

6

6

6

6

3110

3580

3730

4450

5160

5990

7060

6

6

6

6

6

6

6

3900

4490

4690

5590

6490

7530

8800

6

6

6

6

6

6

6

4710

5420

5660

6740

7830

9080

10710

6

6

6

6

6

6

6

Loading...

Loading...