PNEG-1156ETL Design III Series Grain Stir-Ator CSA 77

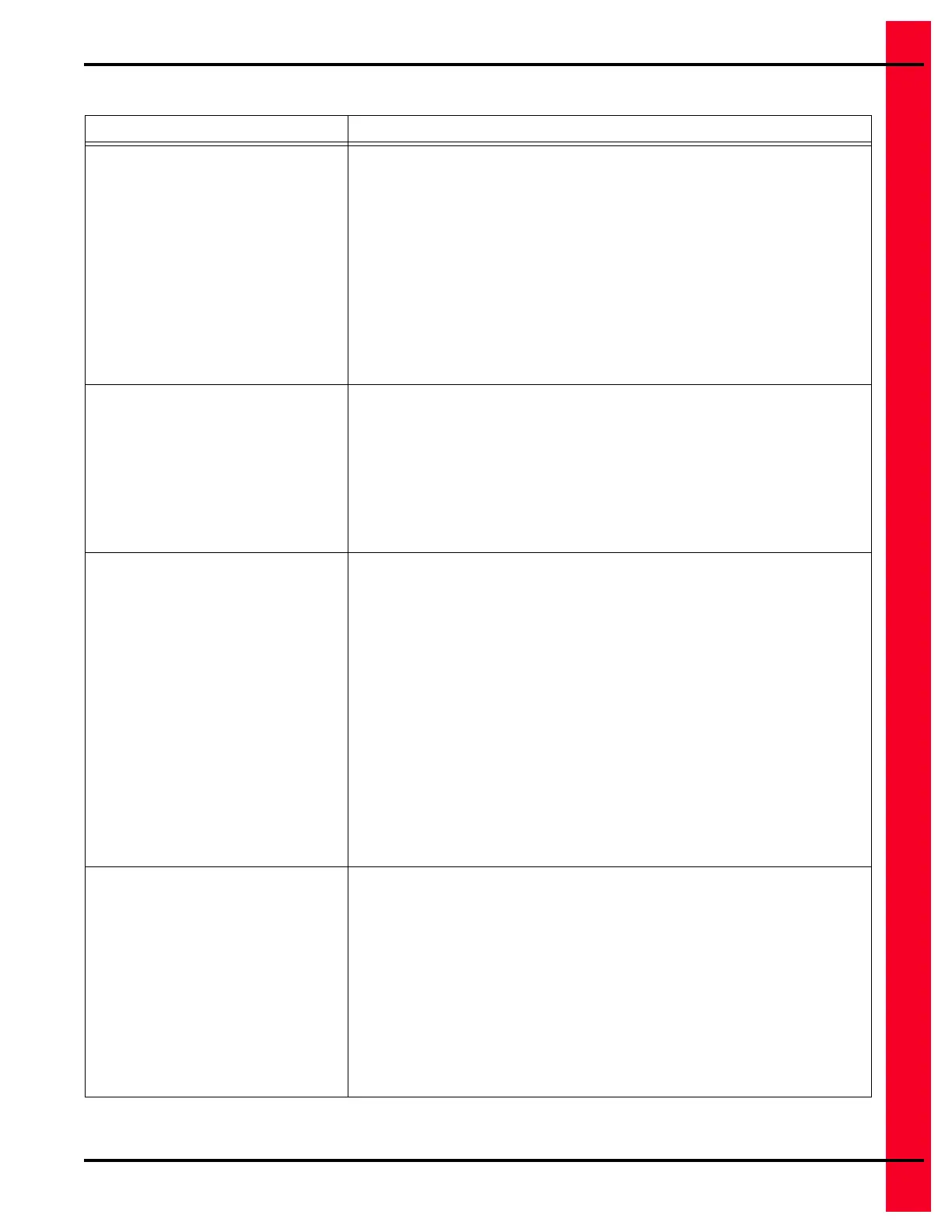

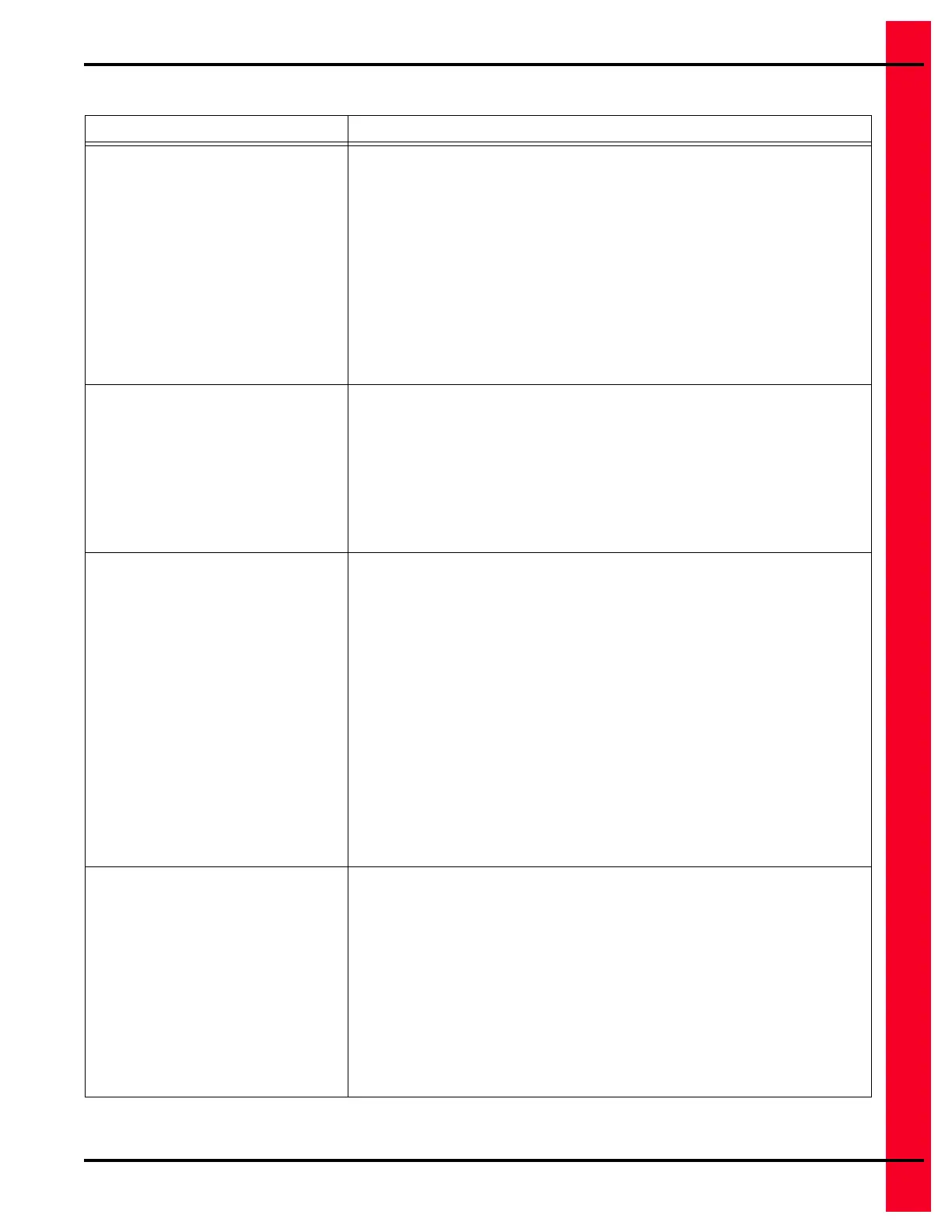

8. Troubleshooting

Design III Stir-Ator Troubleshooting

Problem Probable Cause/Potential Solution

1. Auger motor(s) and gear motor do

not run.

1. Main power is not ON.

2. Contactor in swivel box is bad. (Replace.)

3. Contacts in contactor are dirty or burned. (Clean or replace.)

4. Swivel straps are loose or broken. (Replace strap or clip.)

5. There is a broken, loose or shorted wire. (Call electrician.)

6. Stir-Guard solid state module is bad. (Replace.)

7. Junction box on trolley is improperly wired. (New installation only -

See Wiring Diagrams on Pages 79-82.)

8. Electrical swivel shorted or loose connection.

2. Gear motor runs but not the

auger motor(s).

1. Auger motor overload tripped. (Push reset button on motor.)

2. Augers is stuck in grain. (See Start-Up Procedures on Page 48.)

3. Motor is burned out. (Replace.)

4. There is improper wiring at trolley junction box. (New installation only.)

5. Motor HP may not be adequate for length of auger.

6. Fuse is blown. (Replace.)

3. Auger motors run but gear motor

does not.

1. Gear motor fuse is blown. (Replace.)

2. Low voltage or wired for 115 volts. (Check trolley junction box for proper wiring.)

3. Gear motor is burned out. (Replace.)

4. Gear motor case transmission is a problem. (Repair or replace.)

5. Drive chain is off sprocket.

6. Augers trailed back and mercury switch shut gear motor off. (Normal - See

Problems #6 on Page 78.)

7. Tilt switch not adjusted properly.

8. Gear motor and tilt switch not wired properly at trolley junction box.

9. Auger will not advance through grain. (See Problems #6 on Page 78.)

10. Gear motor overload tripped - overload will reset automatically when cool.

Check for excessive drag.

4. Unit has been tripped off by

safety chain.

1. Chain is adjusted too tight. (See Shut Off Chain Adjustments on Page 43.)

2. Switch box handle moves too freely. (Replace box or hook common door spring

from handle to bin roof, being sure it is not too tight to prevent safety shut off from

working properly.)

3. Augers are too long and touch floor.

4. There are foreign object in corn stops.

5. Trolley is binding on frame rails.

6. Cable connector is installed backwards not going around idler pulleys.

7. Check correct length unit for bin size.

Loading...

Loading...