26

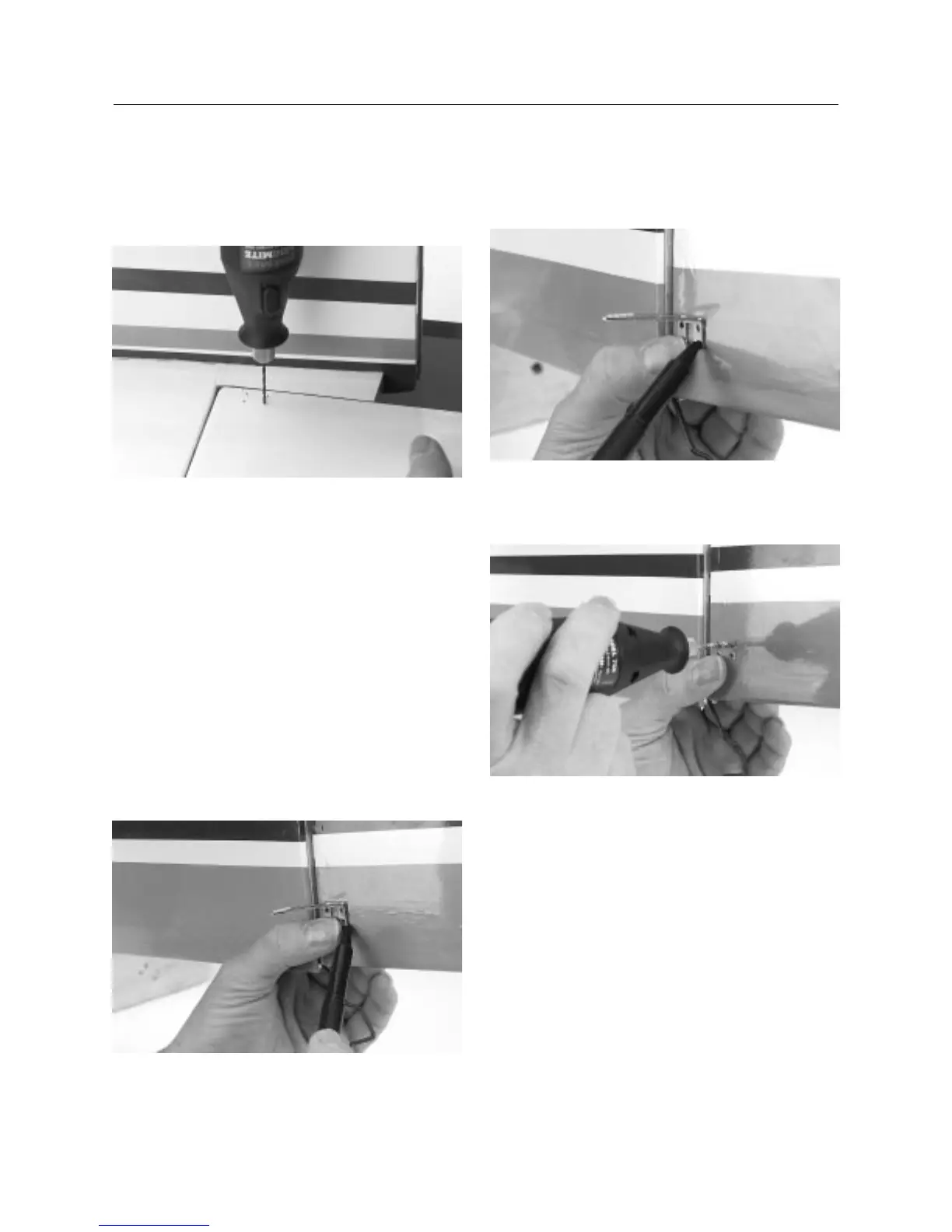

Step 5. Using a 1/16′′ drill bit, drill four pilot holes for the horn.

After the pilot holes are drilled, you can use the 3/32′′ drill bit to

complete the process.

Step 6. Trial fit the standard horn, using the four screws.

Carefully screw in the screws and engage the plastic plate on the

other side. We recommend covering the area around the horn

with masking tape to help prevent damage to the covering in

case the screwdriver slips. Once installed, repeat the process for

the left elevator.

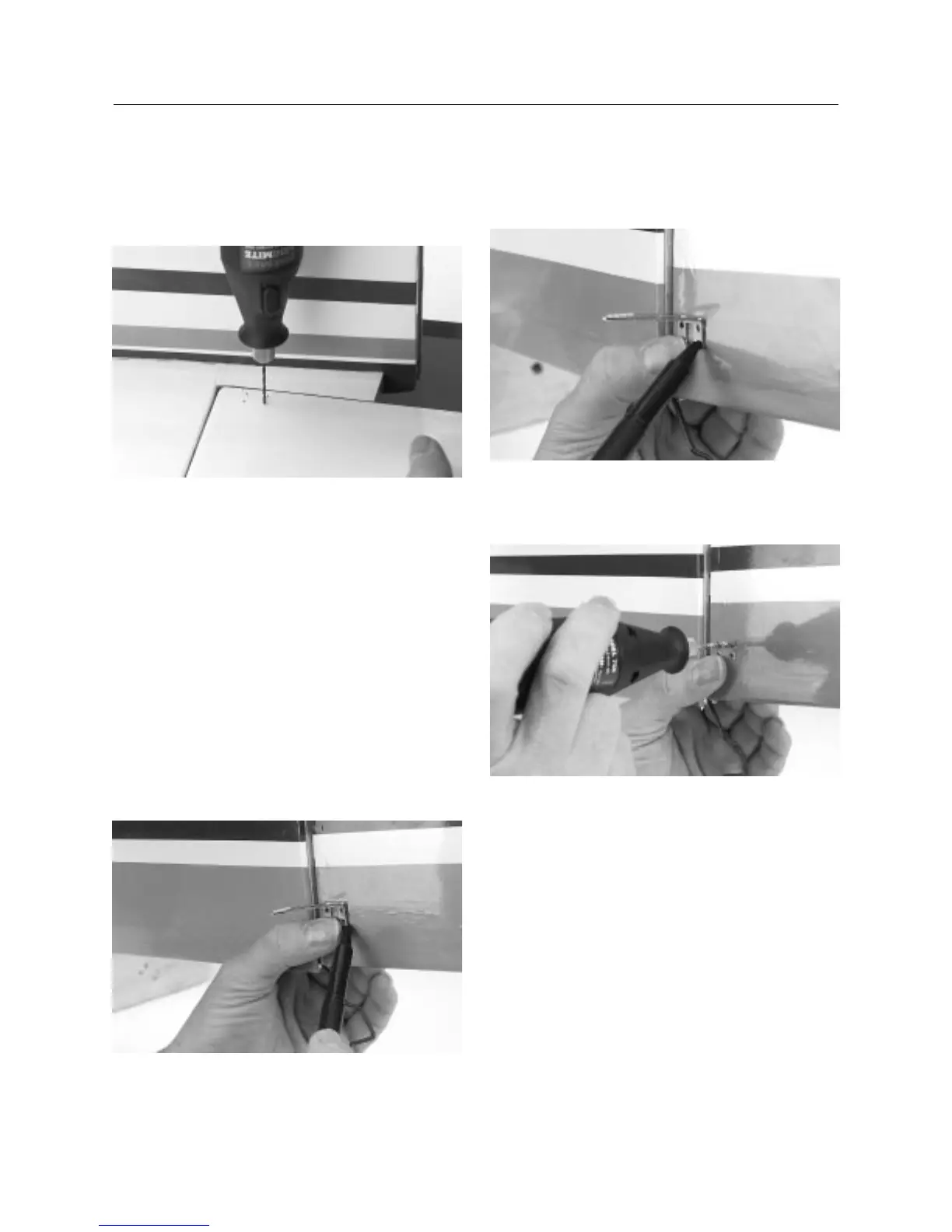

Step 7. Locate a standard and reverse control horn, four screws

and one plastic plate. The reverse “R” control is installed on the

right side of the rudder as if you were sitting in the cockpit. The

standard control horn will be mounted on the left. The rudder

pull-pull control horns will be located 7/16′′ back from the hinge

line of the rudder and approximately 3/8′′ up from the bottom of

the rudder. Mark the location with a felt tipped pen. Trial fit one

horn and make sure the location does not interfere with the tail

wheel wire that was inserted into the rudder.

photo 9-7

Step 8. Once you are satisfied with the location, mark the screw

holes with a felt tipped pen.

Photo 9-8

Step 9. Drill holes using the same procedure as described in

Step 5. Again, use caution when drilling so the wood is not split.

photo 9-9

CONTINUED

Section 9: Installing the Control Horns

Loading...

Loading...