14

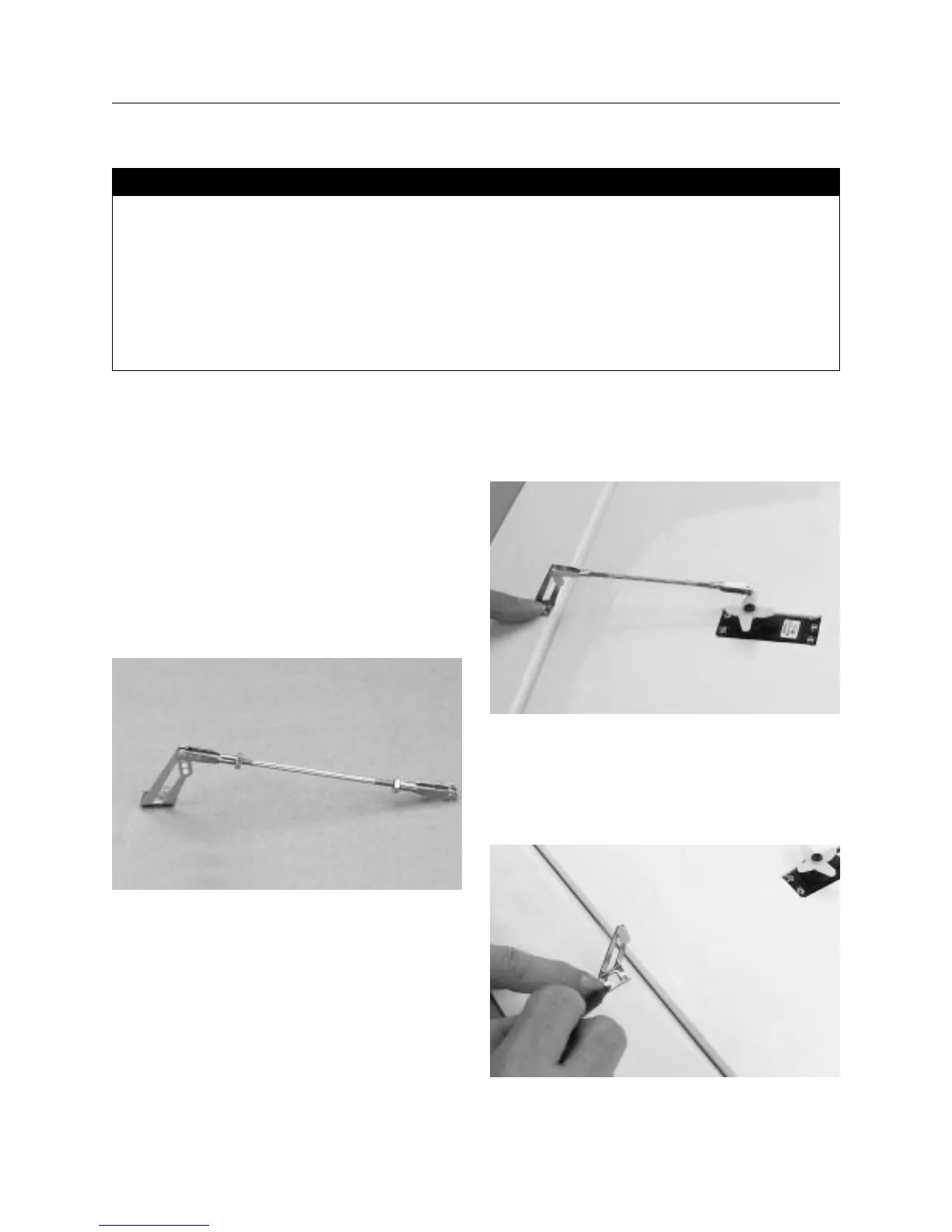

Step 1. For this assembly, you will be using a short (4”)

threaded rod, two clevis and a regular and reverse control horn.

Use the 4/40 nuts as locking devices to keep the clevis from

turning. There is also a locking clip that keeps the clevis from

opening. The reverse control horn has an “R” marked on its

base; the standard horn has no marking. For illustration

purposes, we will describe the hookup of the linkage on the right

wing panel.

Step 2. Thread a 4/40 nut and clevis on each end of the

threaded rod. Next locate the standard horn. The mounting hole

plate should point toward the wing center. The link assembly

goes on the outer servo arm or the one pointing to the wing tip.

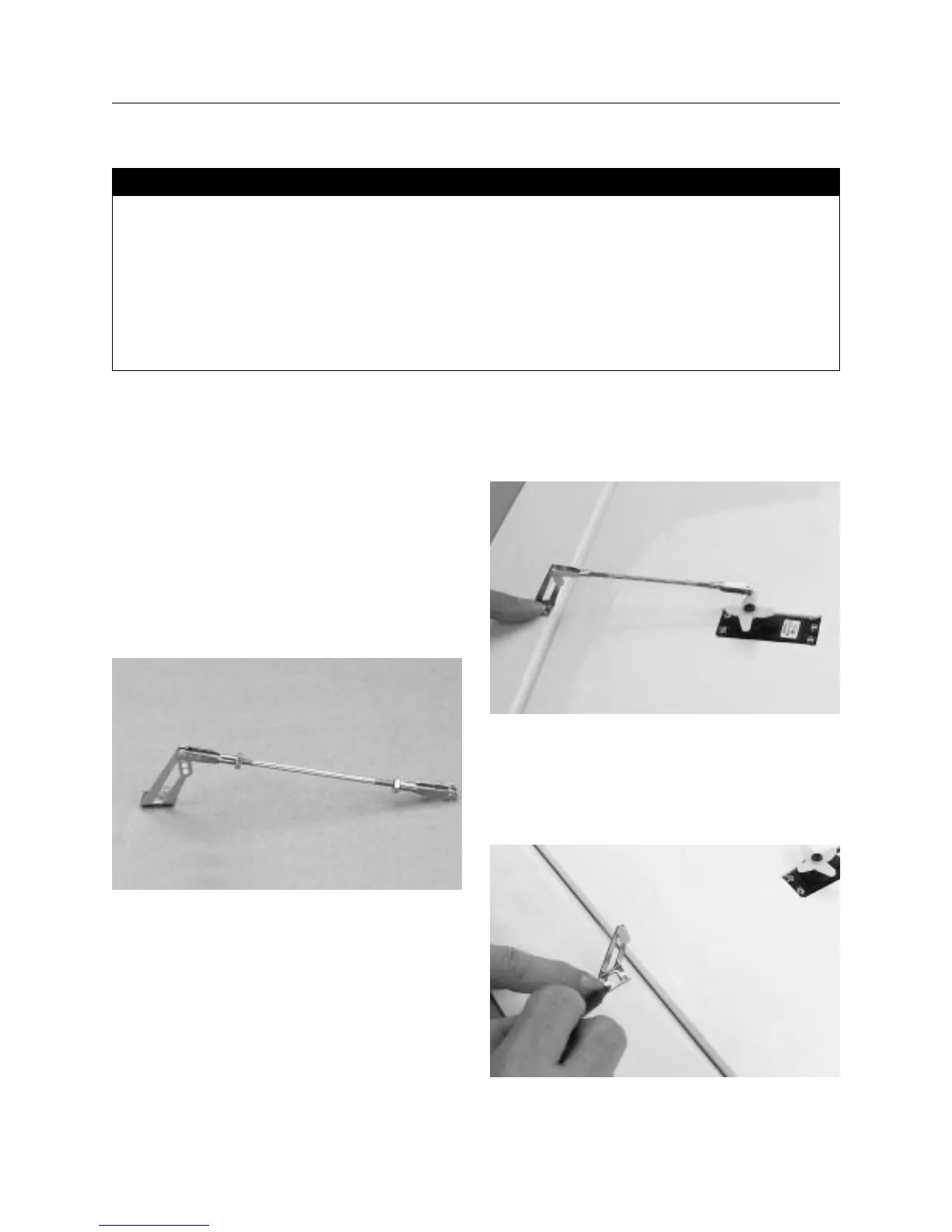

Step 3. To establish the length needed, trial fit the horn and

linkage to the servo arm. Adjustments in length are made by

screwing one or both clevis in or out. The control horn should be

positioned so the holes are over the center line of the hinge line.

Step 4. Once satisfied with the horn location (it should be a

straight line from the servo arm to the horn), mark the location

with a felt tipped pen. You will note the servo is positioned at an

angle to the wing, but is 90 degrees to the aileron hinge line.

Section 4: Installing the Aileron Linkage

• Wing assembly from Section 2

• Left control horn

• Right (reversed) control horn

• Plastic plate (2)

• Screws (8)

• Short (4′′) threaded rod (both ends) (2)

• Clevis (4)

• 4/40 nuts (4)

• Medium Phillips screwdriver

• Drill

• Drill bits: 1/16′′, 3/32′′

• Felt tipped pen

• Moto-Tool

Parts Needed Tools and Adhesives Needed

Loading...

Loading...