8

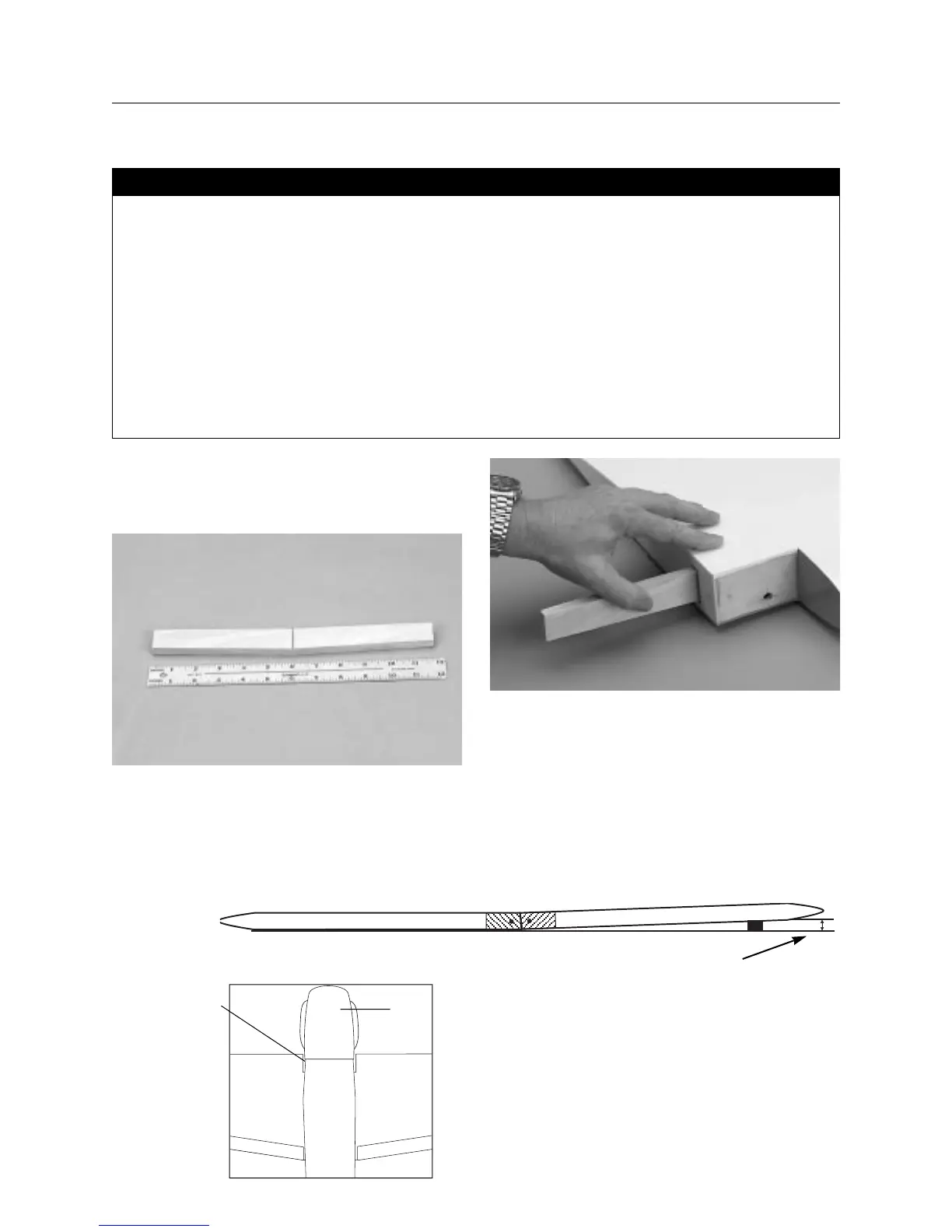

Step 1. Locate the dihedral brace (also called the wing joiner).

Using the ruler, determine the center of the brace and mark it

with a pencil.

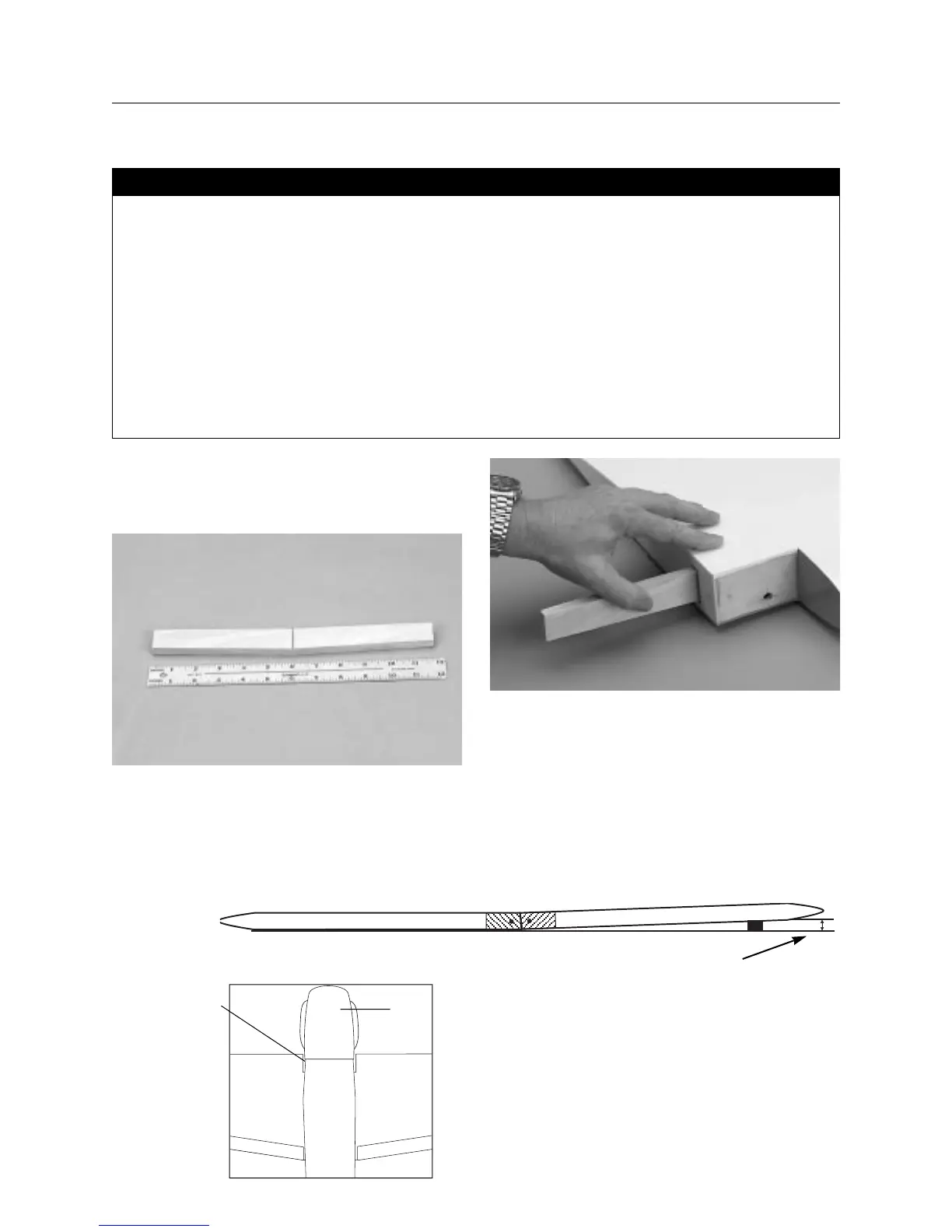

Step 2. Trial fit the dihedral brace into one of the wing panels. It

should insert smoothly up to the center line marked in Step 1.

Now slide the other wing panel onto the dihedral brace until the

wing panels meet. If the fit is overly tight, it may be necessary to

sand the dihedral brace.

Step 3. Check for the correct dihedral angle. Place the wing on

a large, flat surface with one wing panel resting on the flat

surface. The opposite wing tip should be at 3′′ in height from the

surface (see illustration below). If necessary, sand the dihedral

brace until this is achieved. There should be no gaps in the wing

center.

Step 4. To check for adequate clearance of the cowl between the

wing’s leading edge and the fuselage, trial fit the wing together

and temporarily install on the fuselage with the cowl installed. If

the clearance is not adequate, install the extra plywood center

wing rib to provide the necessary clearance (see diagram at left).

• Right/left wing panels

• Dihedral brace

• Plywood wing dowel plate

• Wooden dowels

• Wing bolt plates

• Wing trim tape (white)

• 30-minute epoxy

• 6-minute epoxy

• Epoxy brush

• Masking tape

• Hobby knife

• Rubbing alcohol

• Paper towels

• Wax paper

• Ruler

• Pencil

• Medium sandpaper

• Mixing stick

Parts Needed Tools and Adhesives Needed

Section 2: Joining the Wing Halves

3′′

Clearance

Cowl

Wing

Fuselage

Loading...

Loading...