9

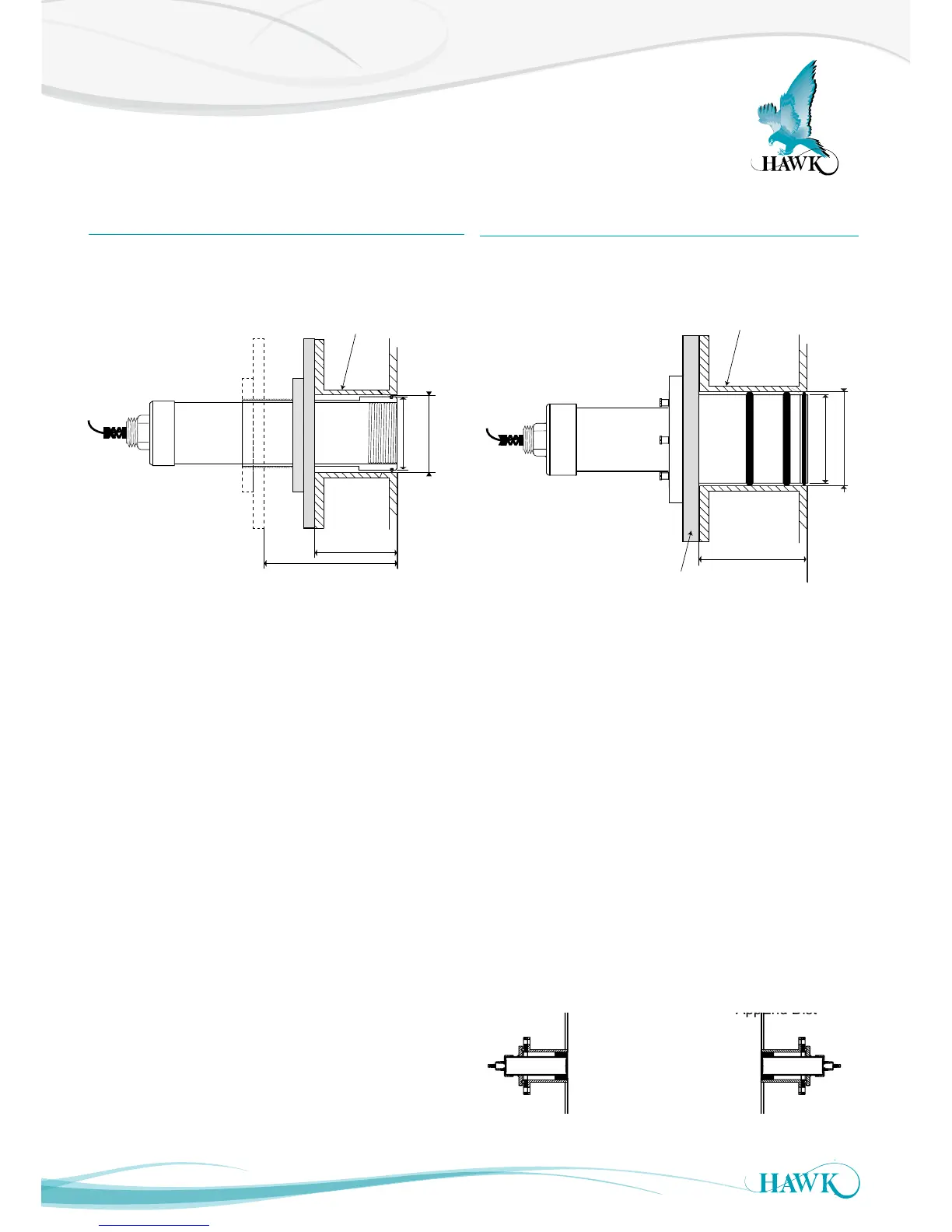

Mounting Dimensions & Instructions

Gladiator Acoustic Switch Series

C

A B

STANDARD 4” ANSI FLANGE DIMENSIONS

FLANGE A (PCD) B (OD)

TYPE mm in. mm in.

C (Hole)

mm in.

FA4 190.5 7.5 228 9.0 19 0.75

SIZE

4”

No.

Holes

8

100mm (3.9”)

102mm (4.0”)

123mm (4.8”)

Flange

3 x O-rings

100mm (3.9”)

min.

95mm (3.7”)

max. 165mm (6.5”)

102mm (4.0”)

ID 100-102mm (3.9-4”)

Pipe with 4” ANSI interface

Adjustable Flange Range

ID 100-102mm (3.9-4”)

Pipe with 4” ANSI interface

General Mounting Instructions

• The mounting location must be away from the

material flow path.

• Sleeve face should be flush with vessel wall interior

• O-rings form both a steal and act as acoustic

de-coupling with the vessel. If required use a cavity

filler (such as a silicone) to prevent material ingress

around the sleeve.

• Material ingress between the sleeve and mounting

can create acoustic coupling which can reduce

sensor performance

• If there is potential for sensor face wear, the

titanium version must be used

• If there is potential for high volume rock impact,

consider a protective hood above (not in front of)

sensor face location.

• Avoid mounting close to perpendicular walls where

material build up can bridge to the Transducers.

• Avoid mounting close to perpendicular walls where

material build up can bridge to the Transducers.

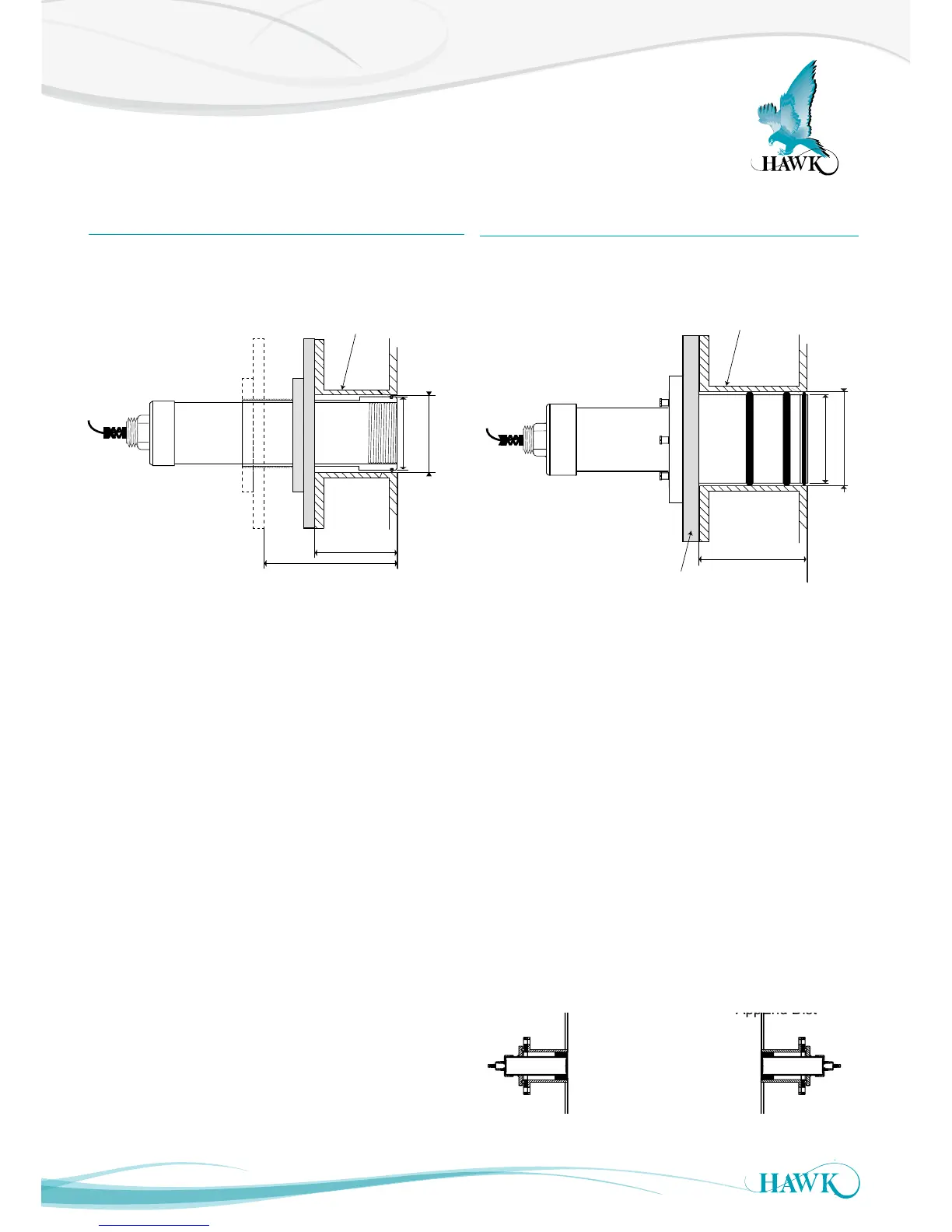

C

A B

STANDARD 4” ANSI FLANGE DIMENSIONS

FLANGE A (PCD) B (OD)

TYPE mm in. mm in.

C (Hole)

mm in.

FA4 190.5 7.5 228 9.0 19 0.75

SIZE

4”

No.

Holes

8

100mm (3.9”)

102mm (4.0”)

123mm (4.8”)

Flange

3 x O-rings

100mm (3.9”)

min.

95mm (3.7”)

max. 165mm (6.5”)

102mm (4.0”)

ID 100-102mm (3.9-4”)

Pipe with 4” ANSI interface

Adjustable Flange Range

ID 100-102mm (3.9-4”)

Pipe with 4” ANSI interface

Remote Transducer

With GAWSLV-3-X and FA4A-4 Flange

Remote Transducer with Spray Cleaner

With FA4A-4-ASC Flange

• Transducers should be aligned as accurately as

possible for optimum performance.

• Never use the connection cable to carry or extract

the Transducer

Spray Kit Mounting Instructions

• Solenoid and 4 way pipe converter should be

mounted securely.

• Recommend 4 way pipe converter is kept close to

mounting position on transducer - use 1” single pipe

for as much distance as possible.

• Use a converter if required to interface with 1”

HAWK recommended pipe connection.

ChuteWidth

AppStart Dist

AppEnd Dist

Live Measured Range

Distance Between

Transducers

Min. 400mm (15.7")

Minimum Range

Loading...

Loading...