HEIDENHAIN TNC 426, TNC 430 113

5.3 Tool Compensation

Radius compensation: Machining corners

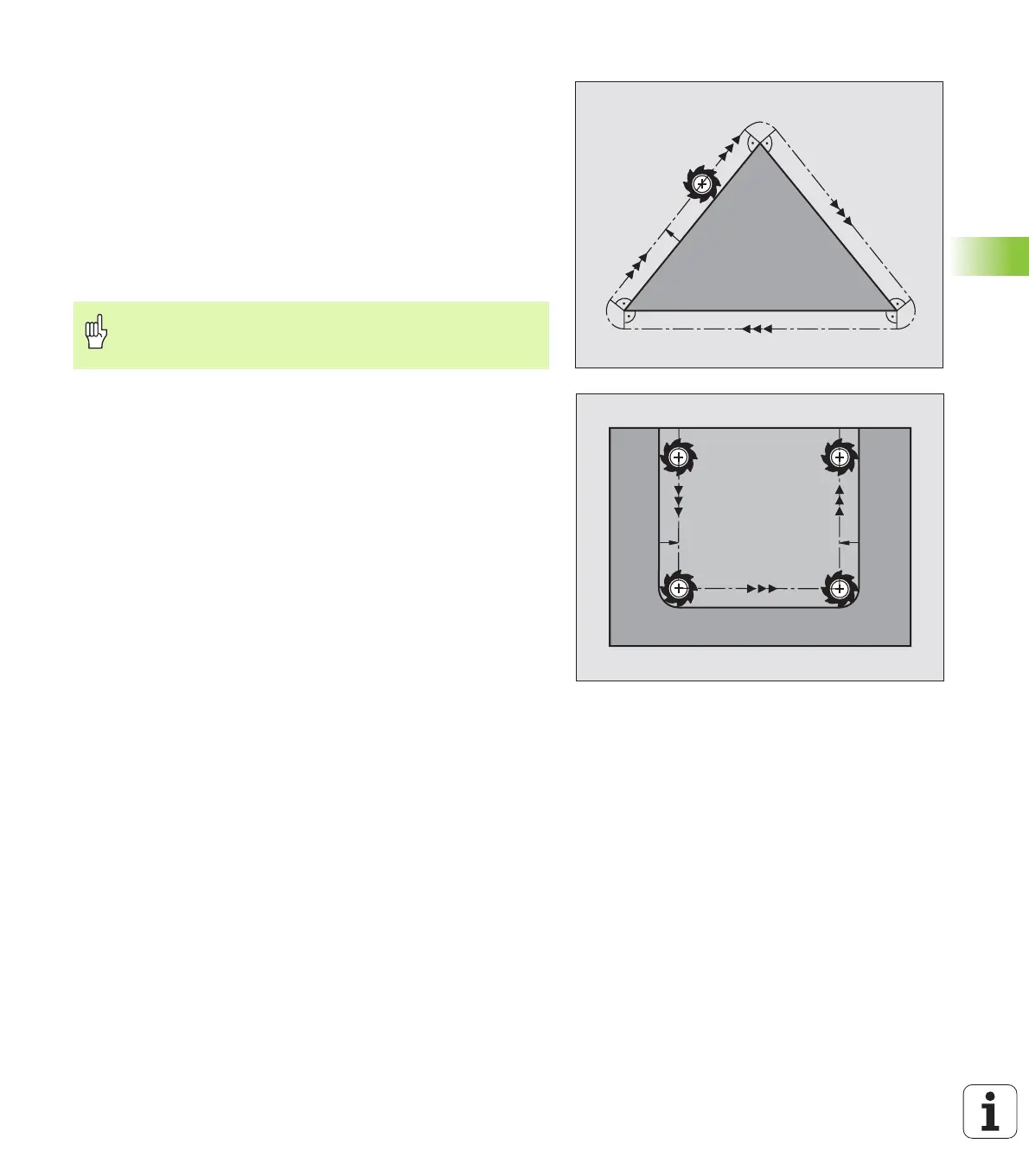

n Outside corners

If you program radius compensation, the TNC moves the tool

around outside corners either on a transitional arc or on a spline

(selectable via MP7680). If necessary, the TNC reduces the feed

rate at outside corners to reduce machine stress, for example at

very great changes of direction.

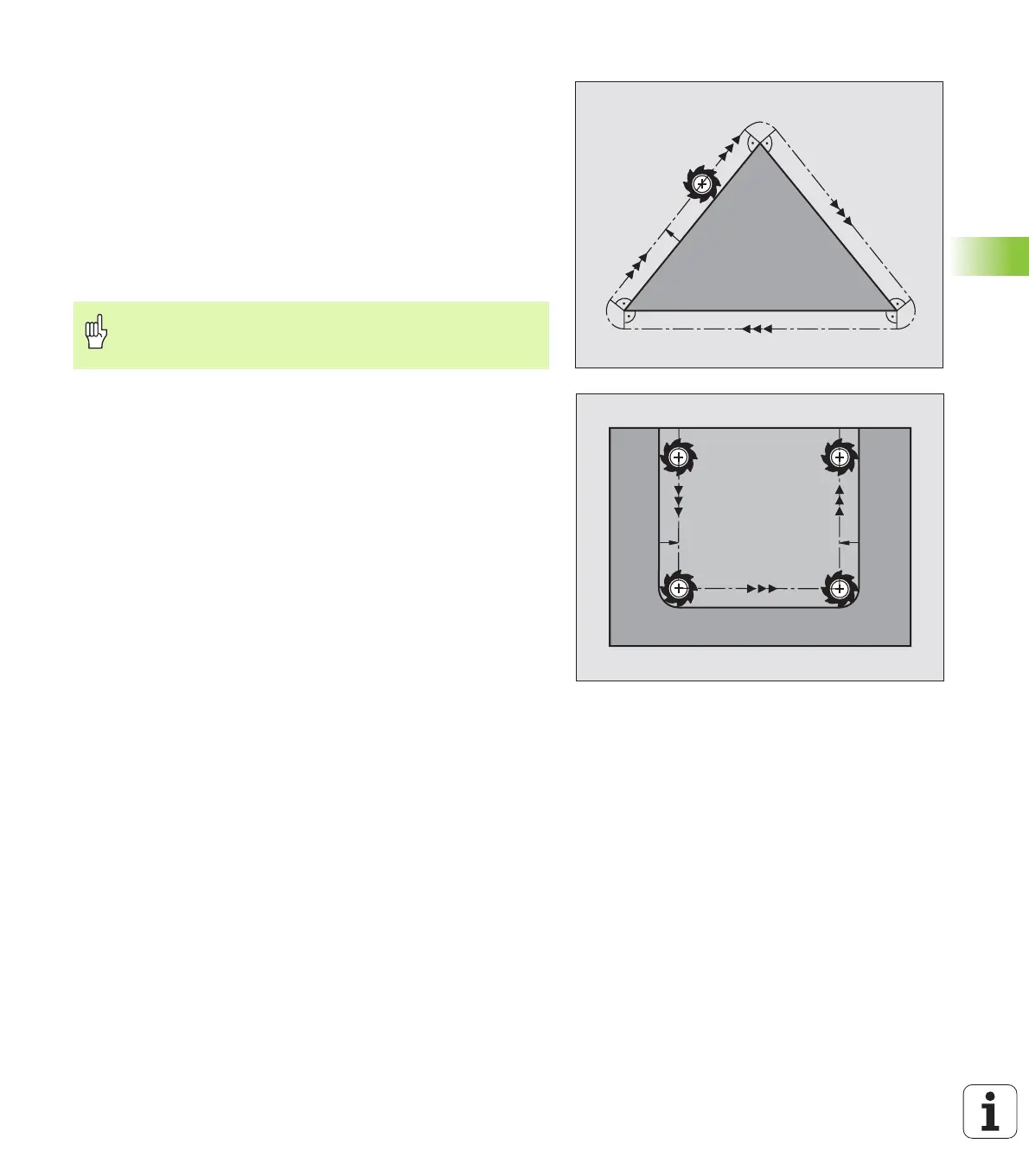

n Inside corners

The TNC calculates the intersection of the tool center paths at inside

corners under radius compensation. From this point it then starts

the next contour element. This prevents damage to the workpiece.

The permissible tool radius, therefore, is limited by the geometry of

the programmed contour.

Machining corners without radius compensation

If you program the tool movement without radius compensation, you

can change the tool path and feed rate at workpiece corners with the

miscellaneous function M90, See “Smoothing corners: M90,” page

181.

To prevent the tool from damaging the contour, be careful

not to program the starting or end position for machining

inside corners at a corner of the contour.

RL

RL RL

Loading...

Loading...