386 10 Programming: Q Parameters

10.10 Preassigned Q Parameters

10.10 Preassigned Q Parameters

The Q parameters Q100 to Q122 are assigned values by the TNC.

These values include:

n Values from the PLC

n Tool and spindle data

n Data on operating status, etc.

Values from the PLC: Q100 to Q107

The TNC uses the parameters Q100 to Q107 to transfer values from

the PLC to an NC program.

Active tool radius: Q108

The active value of the tool radius is assigned to Q108. Q108 is

calculated from:

n Tool radius R (Tool table or TOOL DEF block)

n Delta value DR from the tool table

n Delta value DR from the TOOL CALL block

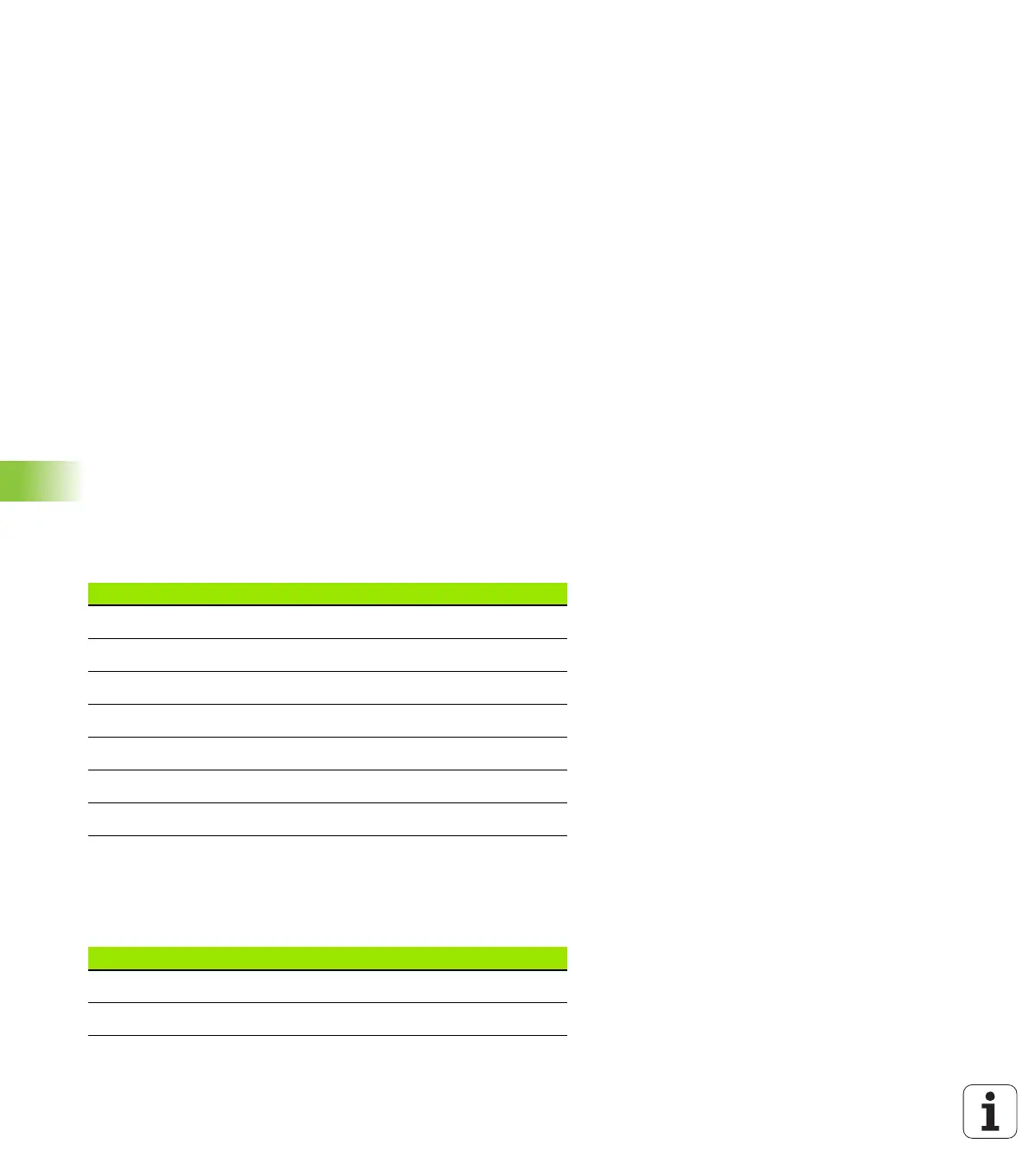

Tool axis: Q109

The value of Q109 depends on the current tool axis:

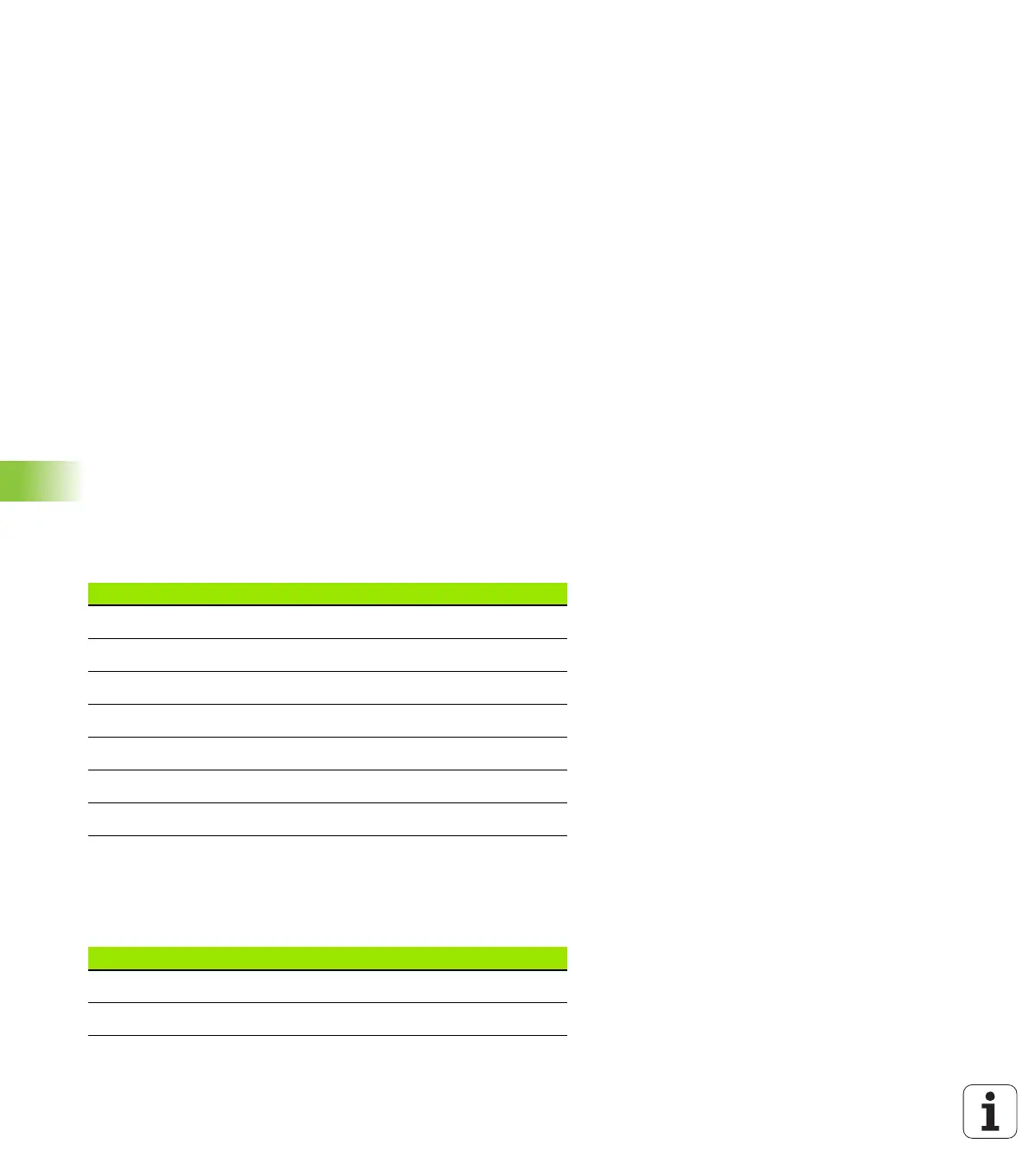

Spindle status: Q110

The value of Q110 depends on which M function was last

programmed for the spindle:

Tool axis Parameter value

No tool axis defined Q109 = –1

X axis Q109 = 0

Y axis Q109 = 1

Z axis Q109 = 2

U axis Q109 = 6

V axis Q109 = 7

W axis Q109 = 8

M Function Parameter value

No spindle status defined Q110 = –1

M03: Spindle ON, clockwise Q110 = 0

Loading...

Loading...