HEIDENHAIN TNC 426, TNC 430 153

6.5 Path Contours — Polar Coordinates

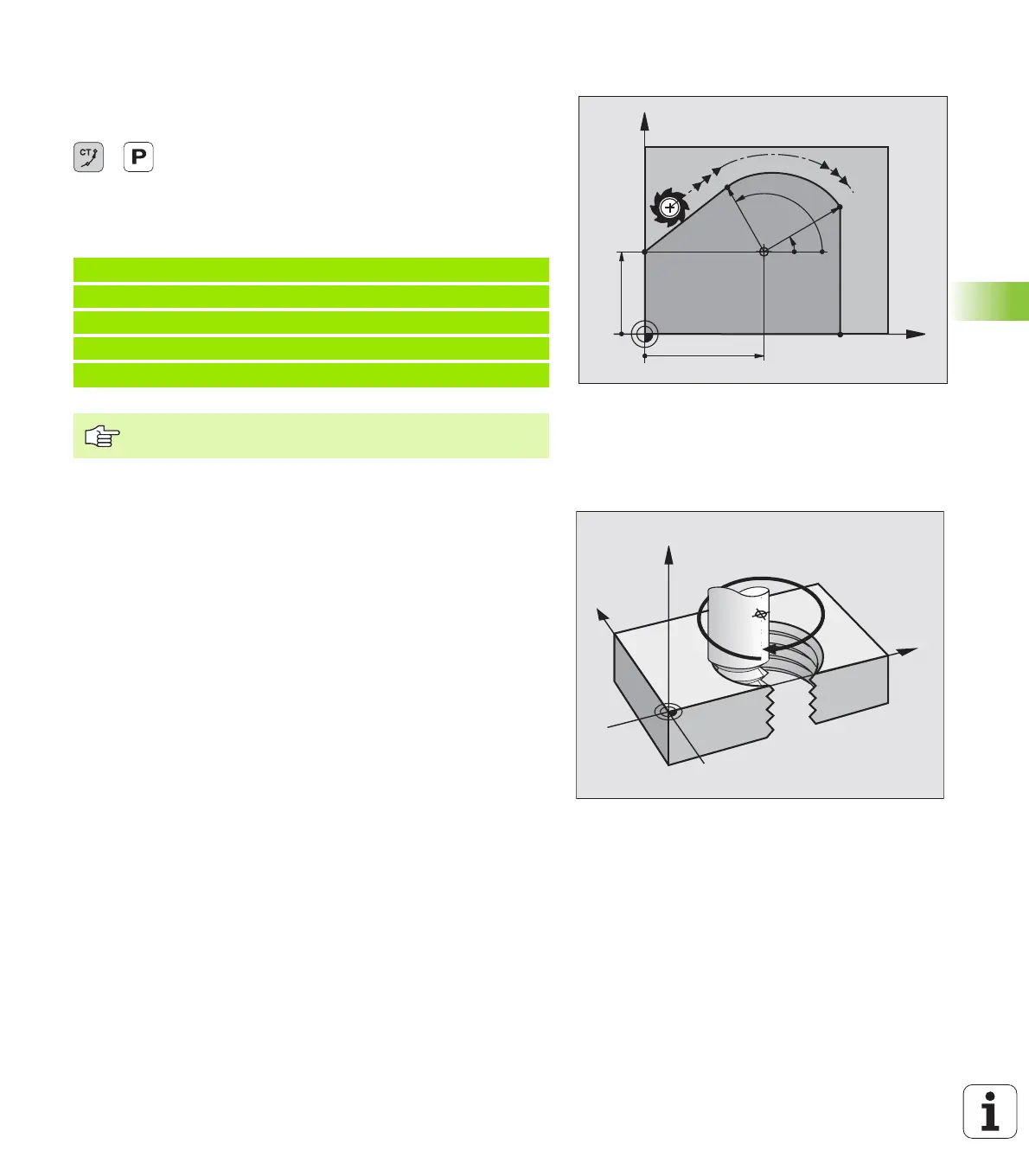

Circular path CTP with tangential connection

The tool moves on a circular path, starting tangentially from a

preceding contour element.

U Polar coordinates radius PR: Distance from the arc

end point to the pole CC

U Polar coordinates angle PA: Angular position of the

arc end point

Example NC blocks

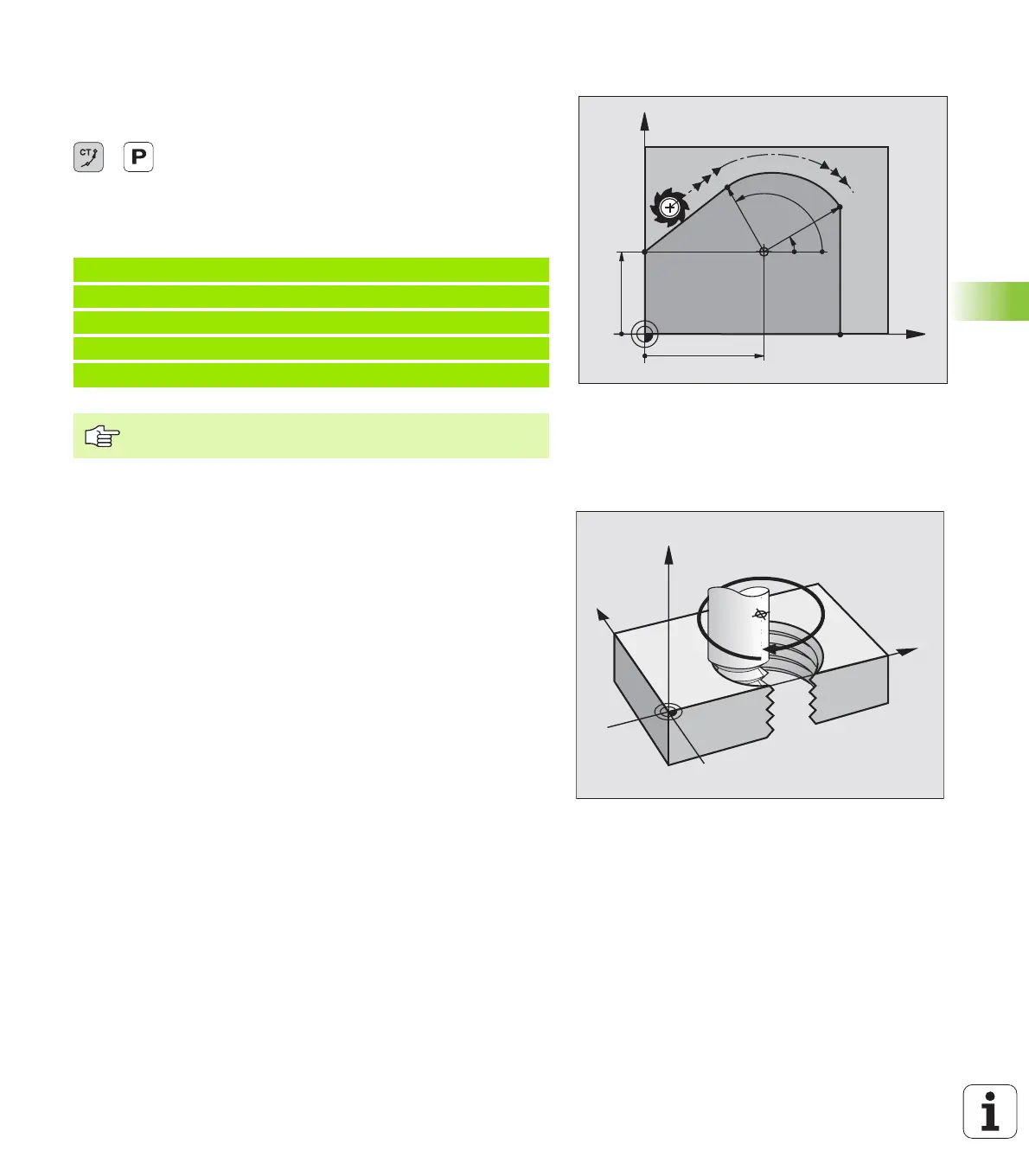

Helical interpolation

A helix is a combination of a circular movement in a main plane and a

liner movement perpendicular to this plane.

A helix is programmed only in polar coordinates.

Application

n Large-diameter internal and external threads

n Lubrication grooves

Calculating the helix

To program a helix, you must enter the total angle through which the

tool is to move on the helix in incremental dimensions, and the total

height of the helix.

For calculating a helix that is to be cut in a upward direction, you need

the following data:

12 CC X+40 Y+35

13 L X+0 Y+35 RL F250 M3

14 LP PR+25 PA+120

15 CTP PR+30 PA+30

16 L Y+0

The pole CC is not the center of the contour arc!

X

Y

40

35

CC

30°

120°

R30

R25

Thread revolutions n Thread revolutions + thread overrun at

the start and end of the thread

Total height h Thread pitch P times thread revolutions n

Incremental total

angle IPA

Number of revolutions times 360° + angle for

beginning of thread + angle for thread

overrun

Starting coordinate Z Pitch P times (thread revolutions + thread

overrun at start of thread)

Y

X

Z

CC

Loading...

Loading...